3. The I/O module

3-24

Festo P.BE-CB-COMP-EN en 1102d

If the set target number of parts types is reached, all further

good parts of the parts type up to the moment when the

small parts conveyor is switched off will be returned to the

conveyor at the actuator position for superfluous good parts.

Bad parts will be output further at the relevant position.

CFul

When the last good part of a counting procedure reaches the

output position for good par ts, the output O/22 on the con-

nection PLC will be set from LOW > to HIGH (“Target num-

ber reached”). The current counter status is ended. The

CHB-C-X shows “cFul”.

All subsequent good parts will be returned to the small parts

conveyor. When the time preset with CheckKon has expired,

the small parts conveyor will be switched off.

In order to star t a new counting procedure, the CHB-C-X

requires the signal “Start new cycle” from the higher-order

controller. In order that the counting cycle can be started, the

pulse LOW > HIGH > LOW must be applied at input I/18.

During the pulse duration t

sc

good parts will still be returned.

The new counting cycle starts with the falling edge at I/18

(see follo wing table).

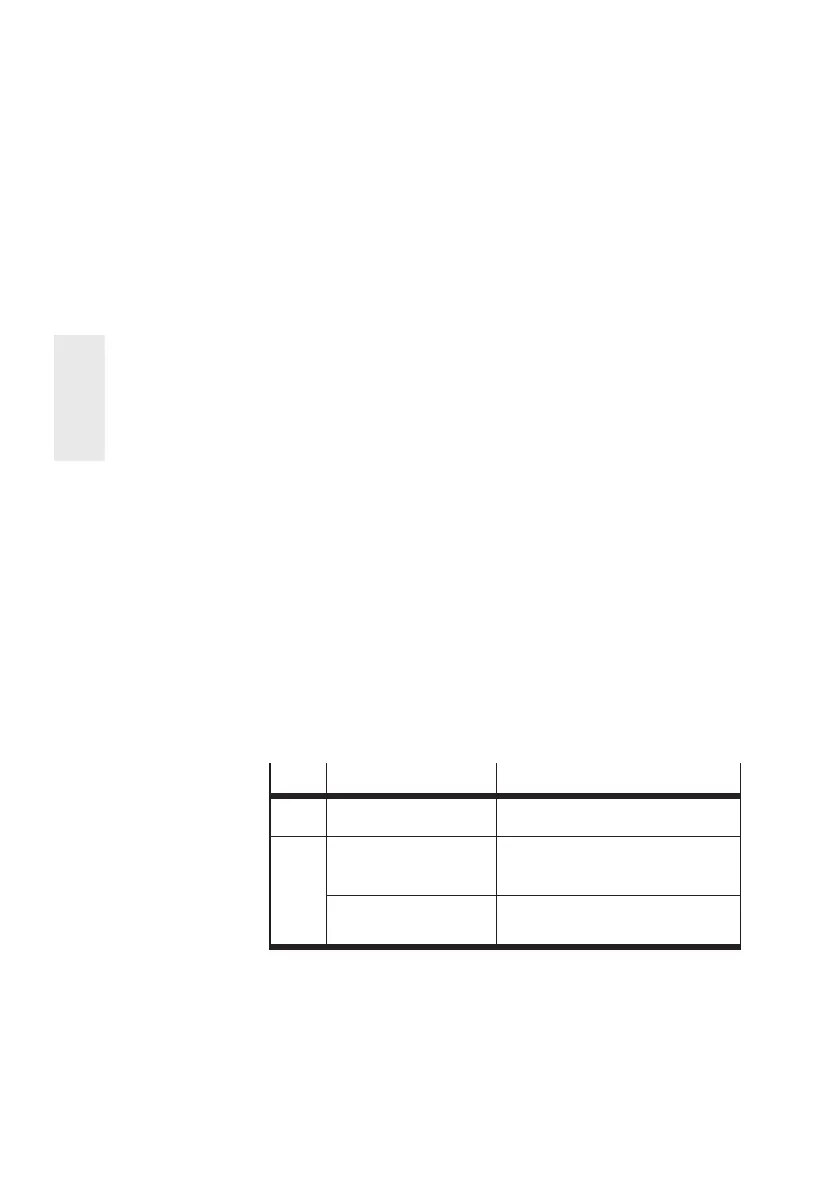

Pin

Signal level Significance

I/18

LOW > HIGH > LOW

Starts new counting cycle

O/22 HIGH Preselected c ounter status

reached

LOW Preselected counter status not

yet reached

Tab. 3/14: Signal sequence for controlling the counting pro-

cedure

Loading...

Loading...