4. Commissioning

4-22

Festo P .BE-MPA-EN en 1108e

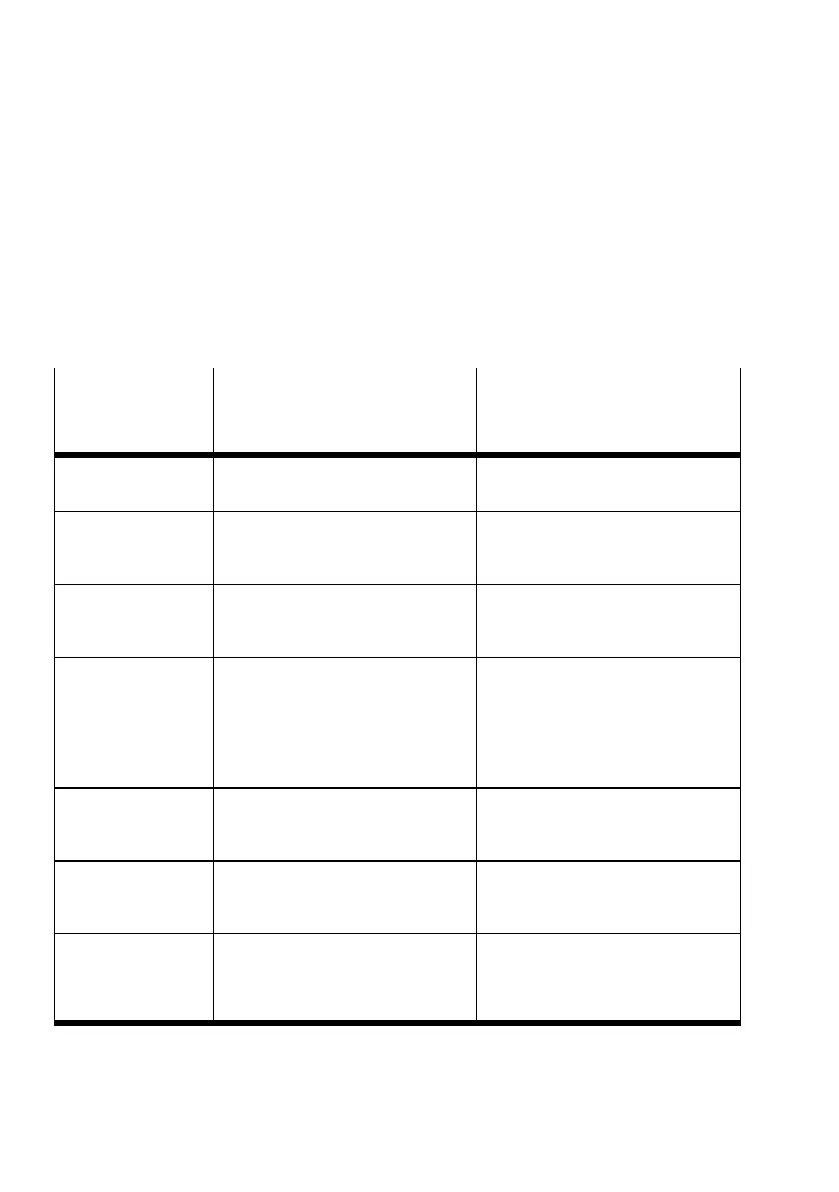

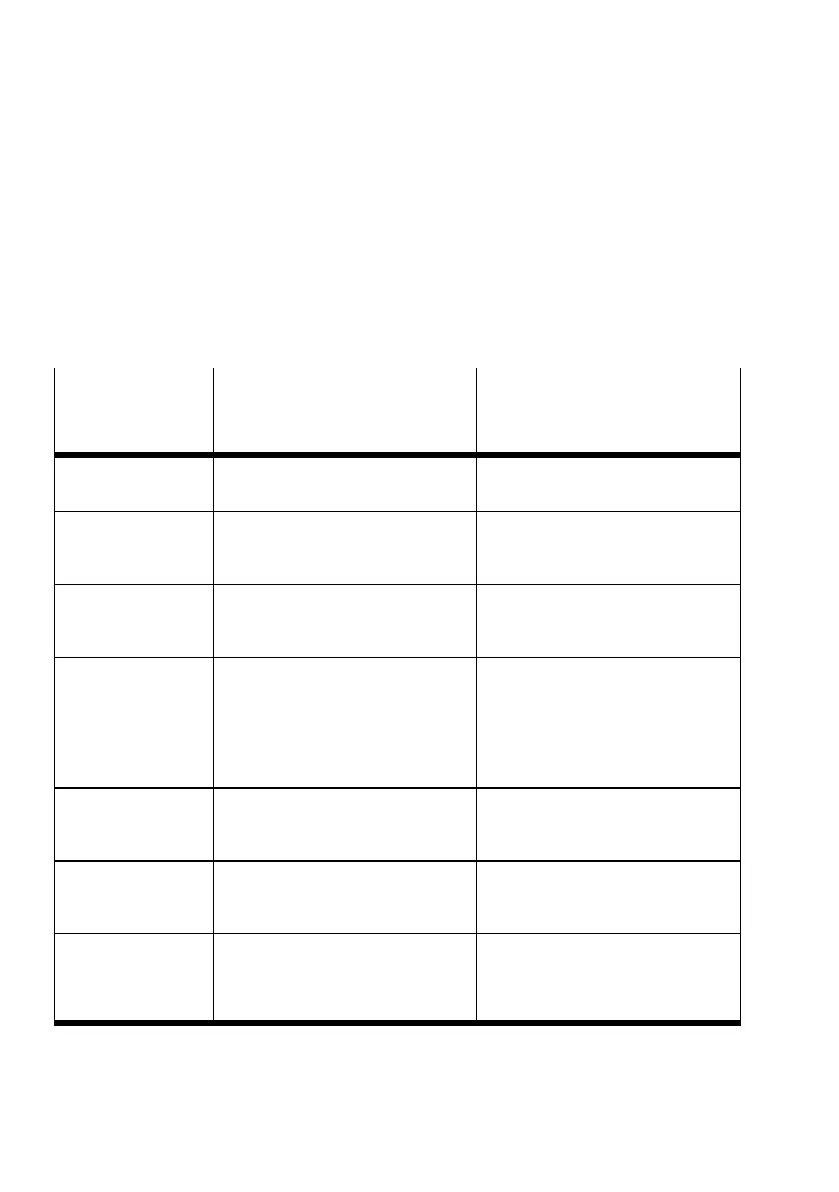

4.7.2 Operating states of the pneumatic system

The following conditions should be fulfilled, in order that the

desired pneumatic operating states listed below can be

achieved:

Desired

pneumatic

operating status

Prerequisites Comment

Zero-leakage – Tubing connected with care

– Regulated pilot air supply

—

Fast reaction Sufficient pressure supply b y means

of pressure supply modules

Exhaust the MPA-S valve terminal via

all exhaust plates or flat plate

silencer

Trouble-free Non-return valves in common

exhaust line

This applies when several systems

with centrally ducted exhaust are

used

Two or more

pressure zones

– Limiting the pressure zones by

means of isolating seals with

blocked channels

– Appropriate number of pneumatic

air supply plates for supplying the

different pressure zones.

Subsequent conversion possible

(see Chapter 5)

Vacuum or

low-pressure

operation

Externally supplied regulated pilot

air supply ( 3 … 8 bar)

Vacuum/Low pressure operation not

with 2x2/2- and 2x3/2-way valves

(Ident.codeD,I,H,K,N)

EMERGENCY STOP of

pressure zones

Guaranteeing the c ontroller function

for the pilot a ir supply despite the

overall supply being switched off

The controller regulates the pilot air

supply to all the valve plates on an

MPA-S valve terminal

Slow star t-up after

EMERGENCY STOP

If control signals are present, the

pilot air supply must have a pressure

of 3 ... 8 bar immediately after being

switched on

Tab. 4/11: Pneumatic operating states

Loading...

Loading...