Manual Flamcomat G4 + Flamcomat Starter G4

We reserve the right to change designs and technical specifications of our products.

37

ENG

8. Maintenance

Electrical supply must be disconnected prior to conducting any maintenance. To supplement, or in addition to,

the stipulations made in the overall project, perform the following:

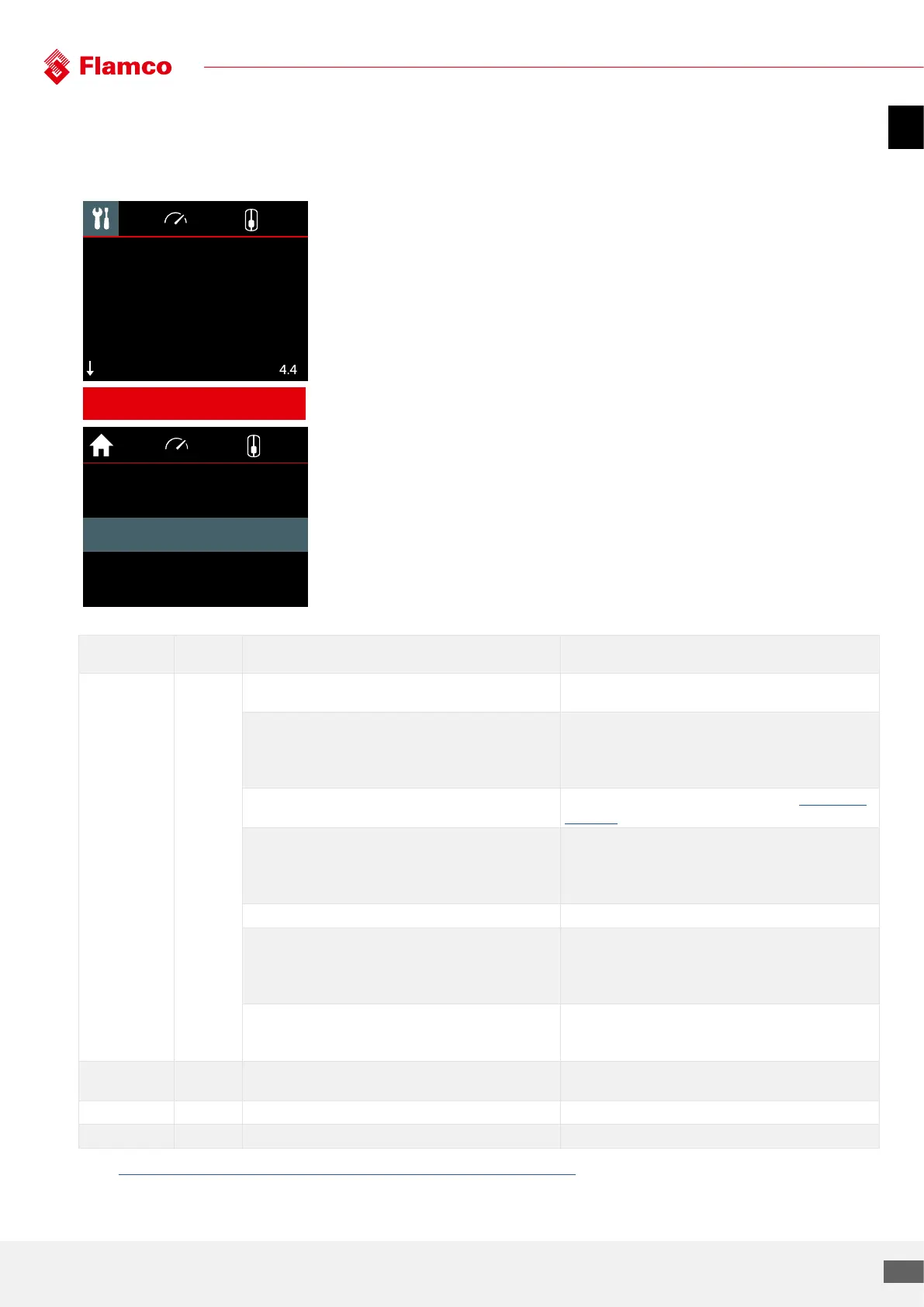

Maintenance due date is shown in menu 4.4.

Maintenance error pops-up when date is due. Error gets stored in the Current

errors/warnings list and Error logbook.

Aknowledging the “maintenance 1 is due” error in the Current errors/warnings

list is equal to resetting the maintenance 1 due date.

Objects, standard scope of supply Service activities, measures

Maintenance 1 365 Days Particle filter 3.8 * Particle filter back-flow security (only when

installed)

Clean filter insert and housing

Air-intake preventer, bleeder valve 1.2 *, automatic breather

3.18*

Clean and check function. Unscrew the cap and take out the

inner spring and ball-bearing for cleaning. Re-assemble in

reverse order. Screw the cap back on and open it with a single

turn.

Primer valve 3.10; 3.11 *

Check and reset the pre-sets as in diagrams (see “Appendix 2.”

on page 41; seal the valve)

Pump 3.3, 3.6 *, valve 1, 2, 3.12, 3.13 *, valve 3 *, water meter

3.14 *

Function check. To be carried out manually by trained and

certified personnel. Other inspections can be done during

operation of the Flamcomat equipment (observe). Bleed pumps

(except for MP/DP 60)

Control unit 3.19*, configuration Inspect and restore the required settings (overview menu)

Vessel 1 *,pump module 3 * Inspect and repair the leak-tightness of all hydraulic

connections to the water areas. Check the screw connections

for tightness, check the exterior for damage, deformation or

corrosion and restore to operational readiness.

Safety valve 3.16 * Function check. To be carried out manually by trained and

certified personnel. This requires the lockshield valve 2.1* on

the connection assembly.

Maintenance 2 1825 Days Inspect vessel internally! Consider recurring inspections, see

general savety instructions!

Maintenance 3 3650 Days Carry out strenght inspection to vessel!

Maintenance 4 584 Days Carry out recurring inspection of electrical equipment!

* See “5.6 Component parts, pump module” on page 19.

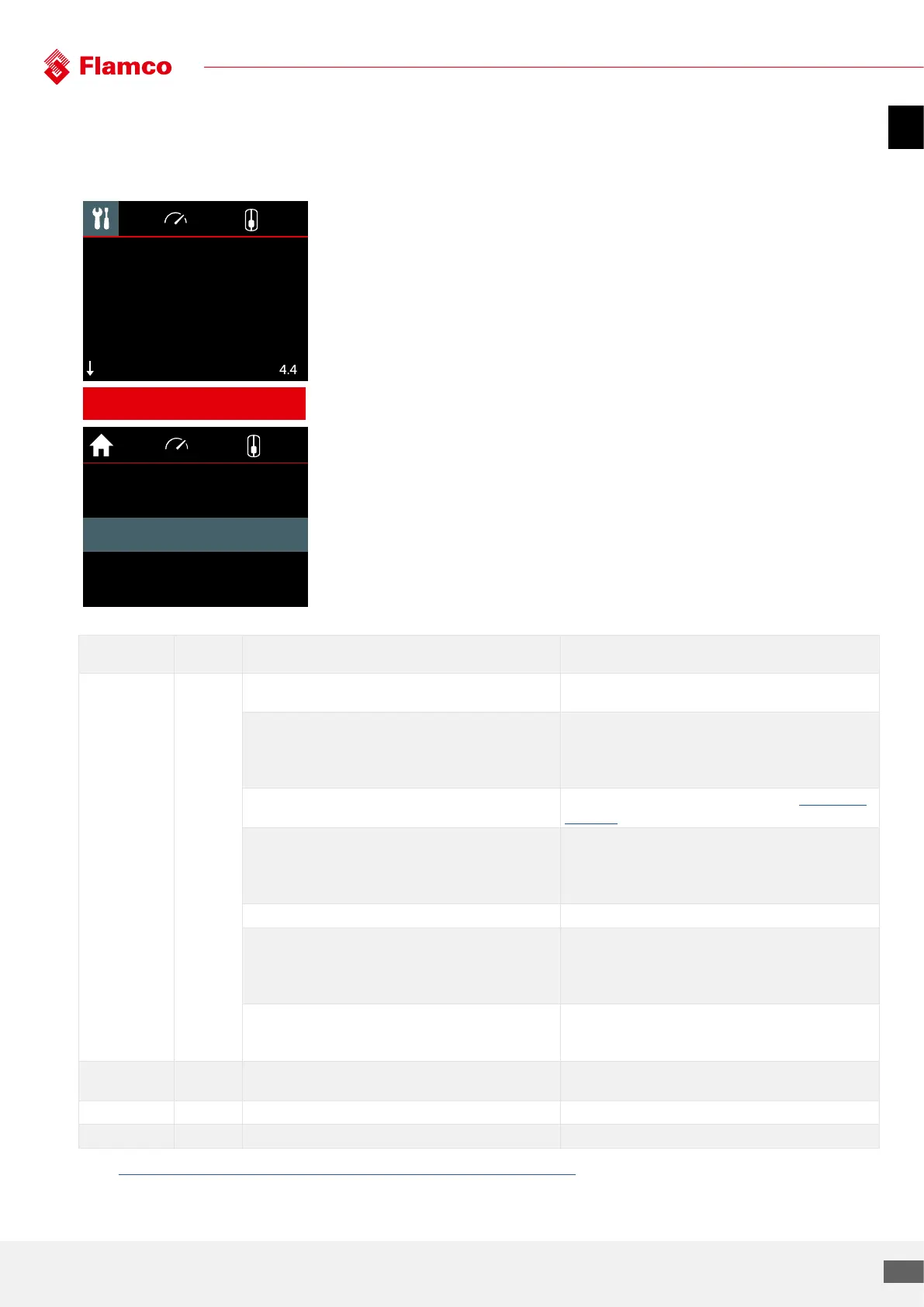

2.2 bar 12 %

Current errors/warnings (1)

>

1 Maintenance 1 is due

<

Maintenance 1 is due

2.2 bar 12 %

Maintenance 1 11-11-2018

Maintenance 2 11-11-2018

Maintenance 3 11-11-2018

Maintenance 4 11-11-2018

Loading...

Loading...