Assembly

5.1 Preparatory work

M3560-02en Edition 09/2022 27

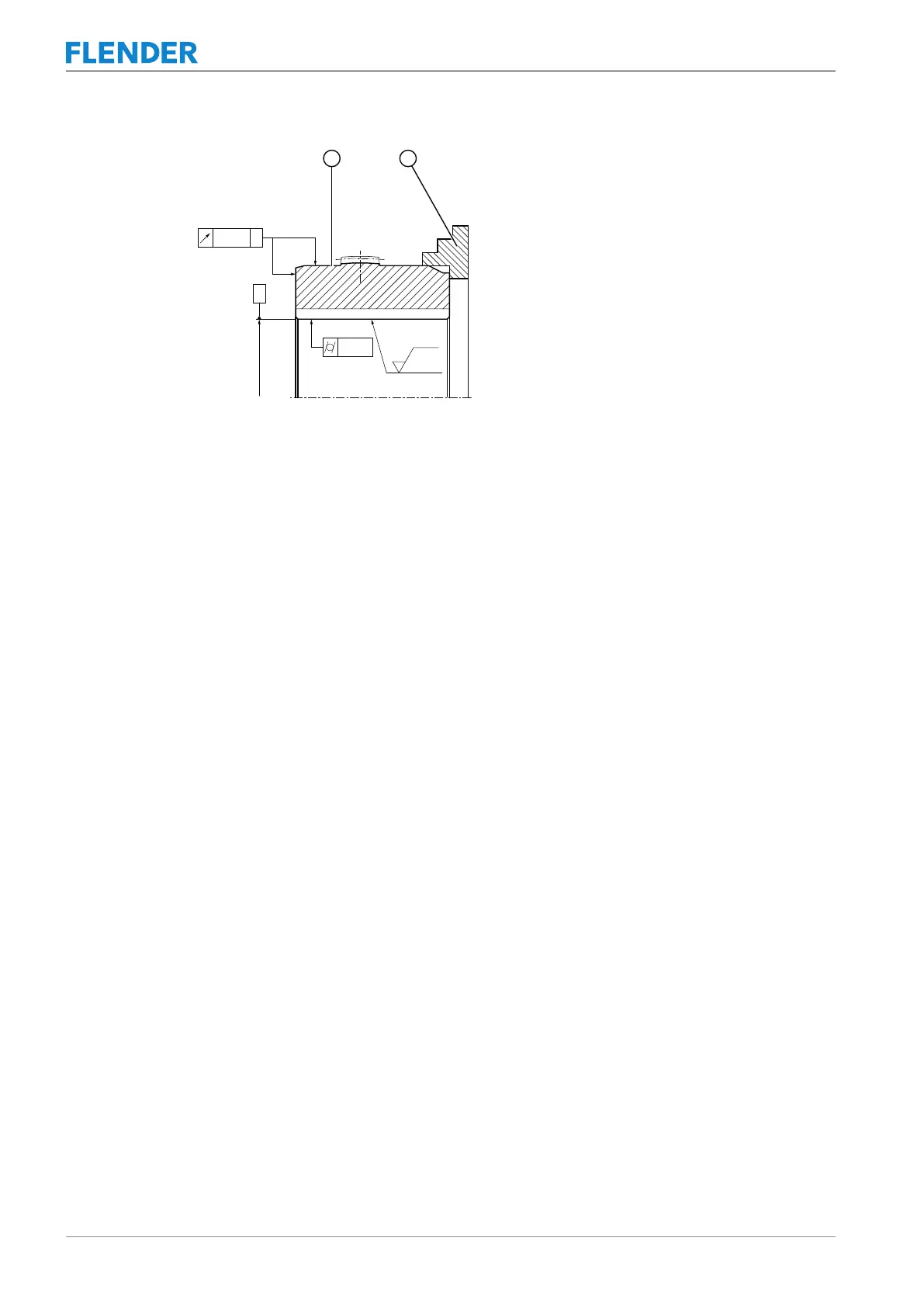

Figure5-1:Tolerances for the finished bore in coupling part 1 (1) or 2 (2)

① Sealing surface

② Clamping chuck

5.1.2 Mill the parallel keyway5.1 Preparatory work

Applicable standards

• For one parallel keyway, machine it according to DIN6885/1ISOP9.

• For two parallel keyways, machine them according to DIN6885/1ISOJS9.

• If you want to mill a parallel keyway that does not correspond to DIN6885/1, please con-

sult Flender.

5.1.3 Machining an axial locking mechanism5.1 Preparatory work

The coupling part 1/2 (1 or 2) is secured by a set screw or an end plate to prevent axial

movements.

Please consult Flender if you want to use an end plate.

Note the following when using a set screw:

• Diameter and axial position of the threaded hole in the hub

• Position of the threaded hole with respect to the parallel keyway

• Selection of the set screw

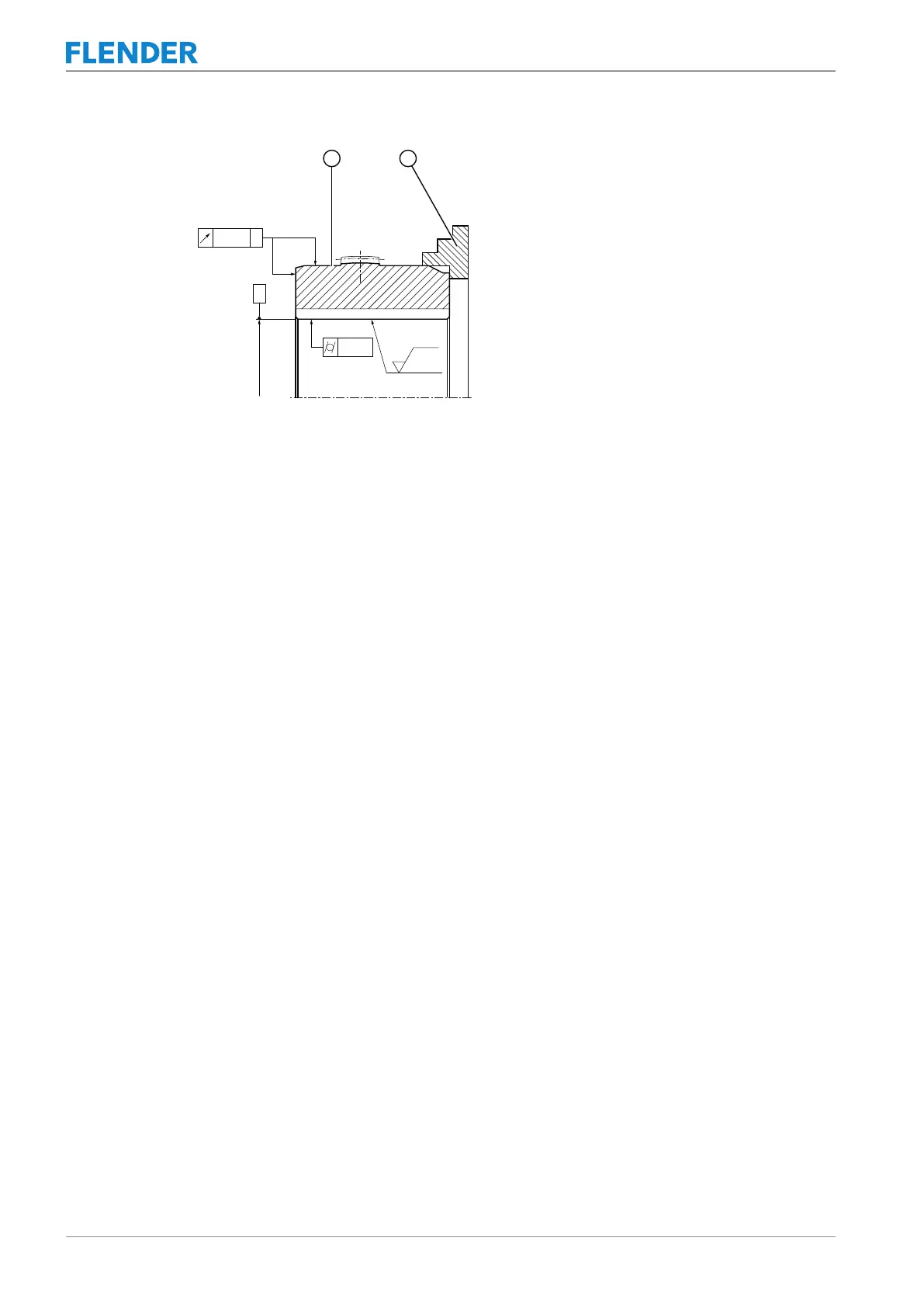

Diameter and axial position of the threaded hole in the hub

The following diagram shows the axial position of the threaded hole.

Loading...

Loading...