Maintenance

8.3 Replacing O-rings

48 Edition 09/2022 M3560-02en

Information

• When replacing the lubricant, keep the amount of remaining lubricant in the coupling as

low as possible.

• It’s easier to change the grease if you add low-viscosity oil to the old grease. Contact

the manufacturer to confirm the compatibility of the oil with the grease in writing.

Procedure

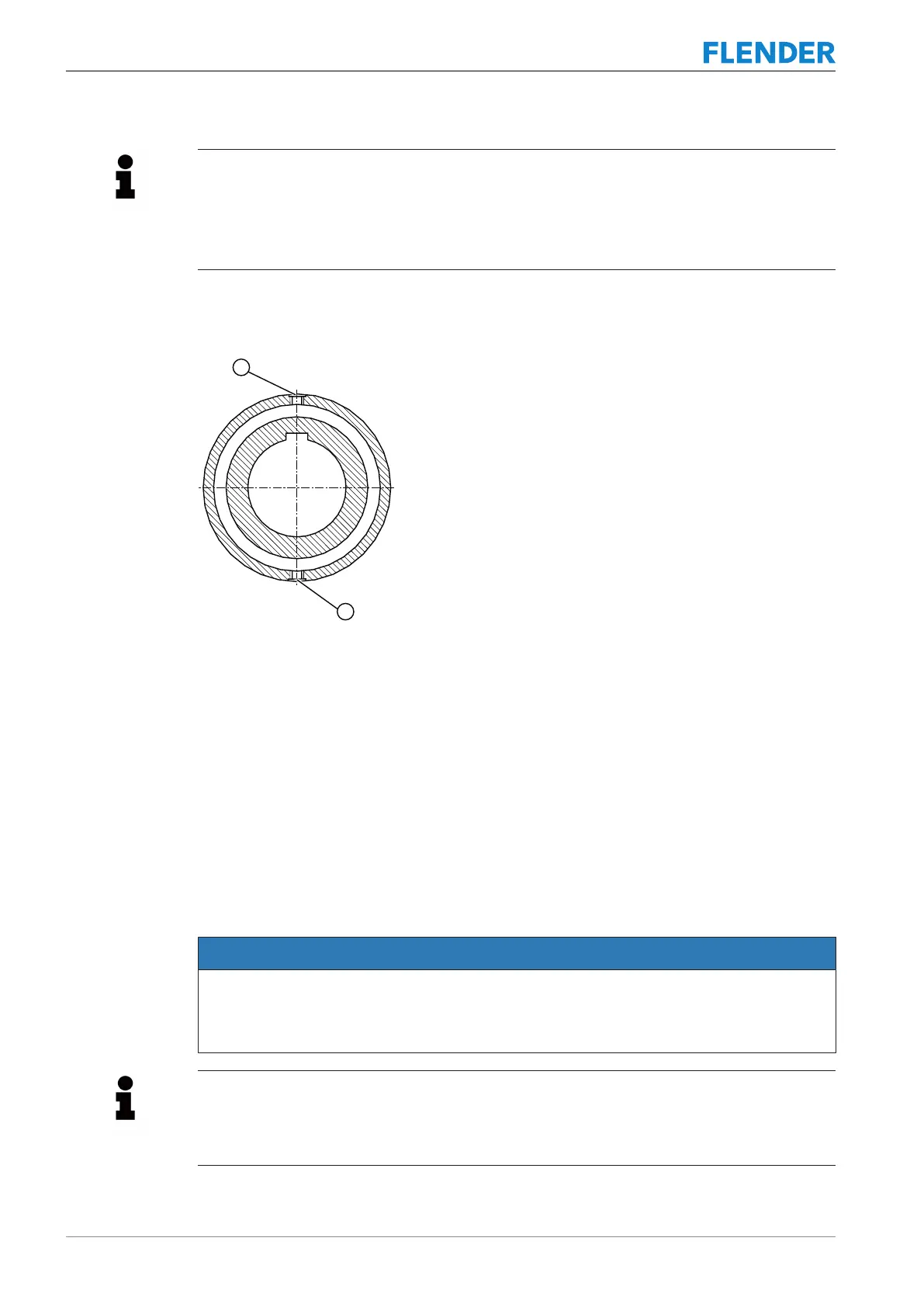

1. Rotate the coupling to the position according to the illustration.

Figure8-1:Draining the lubricant

① Venting hole

② Drainage hole

2. Place a suitable container under the drainage hole.

3. Unscrew all of the screw plugs (6).

4. Make sure you capture all of the lubricant.

5. Disposal of the lubricant. When doing this, carefully observe applicable regulations.

6. Fill with lubricant according to Section Fill with lubricant (Page38).

8.3 Replacing O-rings8.3 Replacing O-rings

NOTICE

Damage to property

Risk of damage to sealing rings from cleaning agents.

• Ensure that the sealing rings do not come into contact with cleaning agents.

Information

If dimensions Q and P from Section Speeds, geometry data and weights (Page61) are

complied with, you can replace the O-rings (12) with cut O-rings (12) without having to

move the coupling apart.

Loading...

Loading...