Operation

7.2 Fault – causes and correction

42 Edition 09/2022 M3560-02en

WARNING

Physical injury

Injury from rotating parts.

• Only carry out work on the coupling when it is at a standstill.

• Secure the drive aggregate against unintentional startup.

• Attach an information notice to the start switch stating clearly that work is being carried

out on the coupling.

• Before starting any work, make sure that the unit is free from loads.

Intended use

The coupling is only approved for the applications specified in these instructions. Please ob-

serve all the stipulations in Section Intended use (Page17).

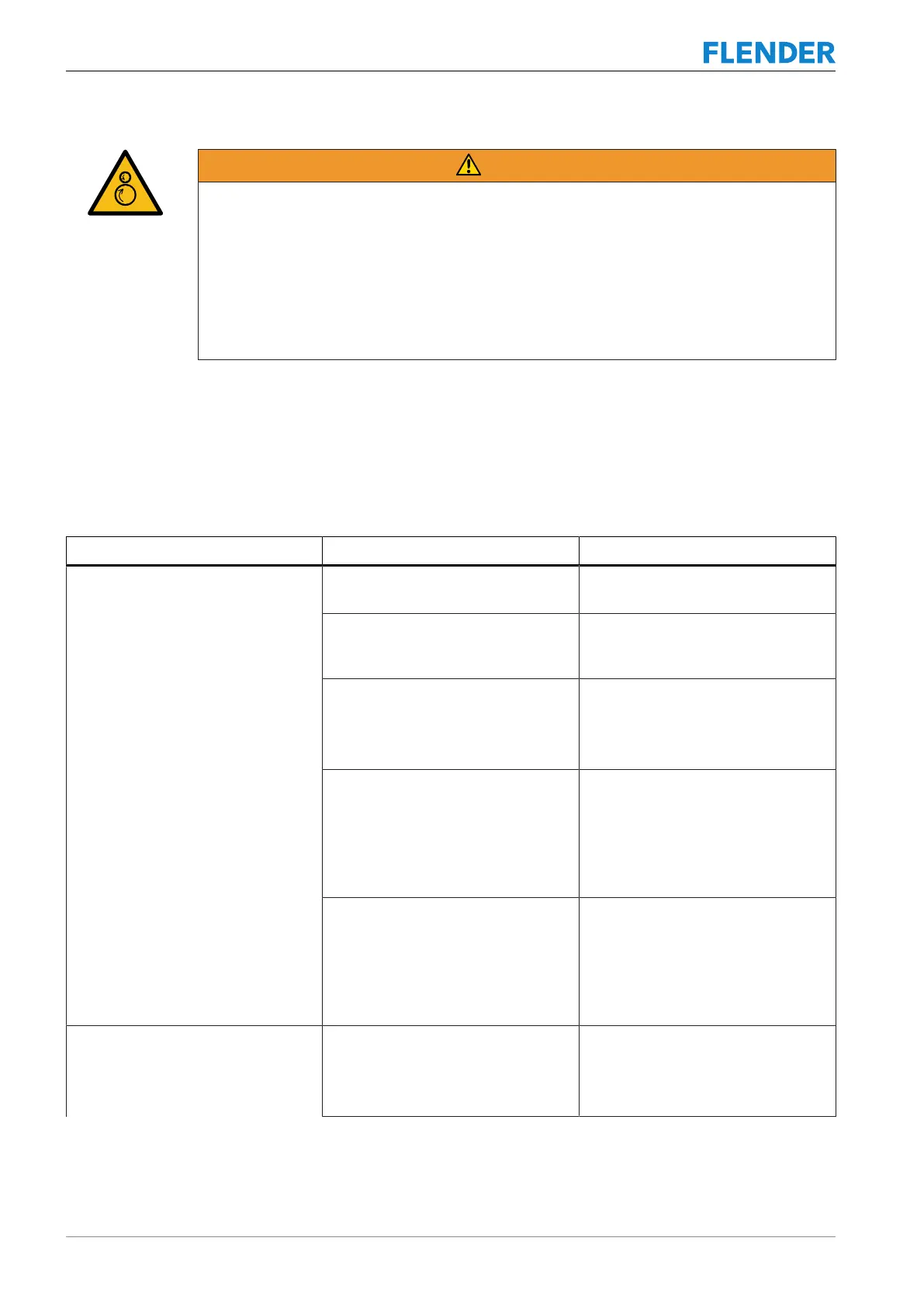

7.2.2.1 Possible faults7.2 Fault – causes and correction

Fault Cause Rectification

Sudden changes in the noise level and/

or sudden occurrences of shocks

Lubricant shortage Follow the instructions given in Section

Fill with lubricant (Page36).

Alignment changes Follow the instructions given in Section

Correcting the changed alignment

(Page45).

Coupling not suitable for the operating

conditions.

Check the possible causes given in

section Unsuitable coupling (Page43).

Use a coupling that is suitable for the

operating conditions.

Incorrect coupling assembly.

Check the possible causes given in

sections Assembly-related causes

(Page43) and Specific assembly-re-

lated and maintenance-related causes

(Page44).

Reassemble the coupling in compliance

with these instructions.

Please observe all the stipulations and

requirements given in chapter As-

sembly (Page25).

Incorrect maintenance of the coupling.

Check the possible causes given in

sections Maintenance-related causes

(Page44) and Specific assembly-re-

lated and maintenance-related causes

(Page44).

Please observe all the stipulations and

requirements given in chapter Mainten-

ance (Page47).

Presence of vibrations Coupling not suitable for the operating

conditions.

Check the possible causes given in

section Unsuitable coupling (Page43).

Use a coupling that is suitable for the

operating conditions.

Loading...

Loading...