Assembly

5.3 Aligning the coupling

34 Edition 09/2022 M3560-02en

The recommended alignment values are specified as numerical values in Distances between

teeth VA and recommended alignment values for angular and radial misalignment

(Page67) . Do not align the coupling more accurately than this, as the lubrication film form-

ation will then be compromised.

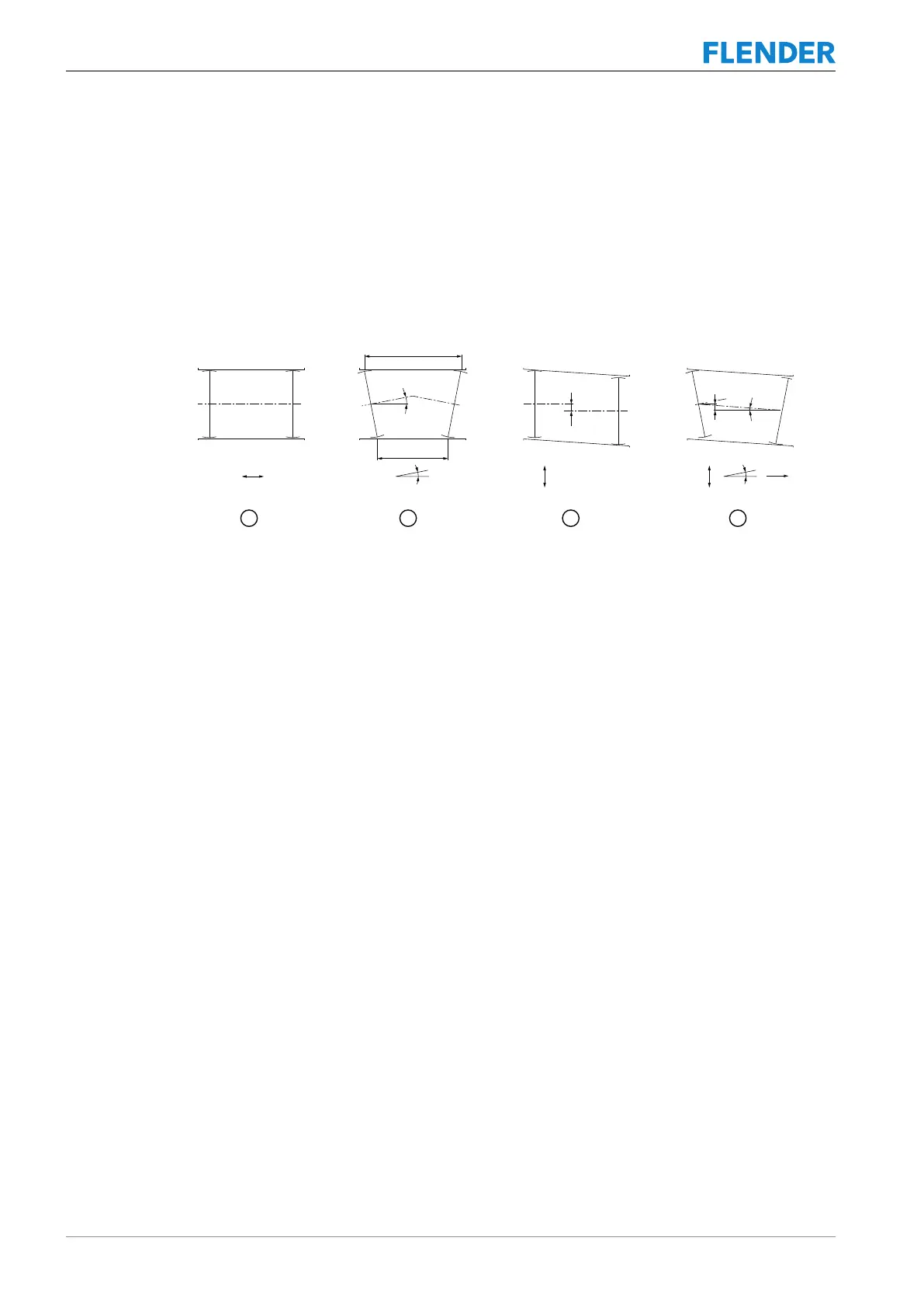

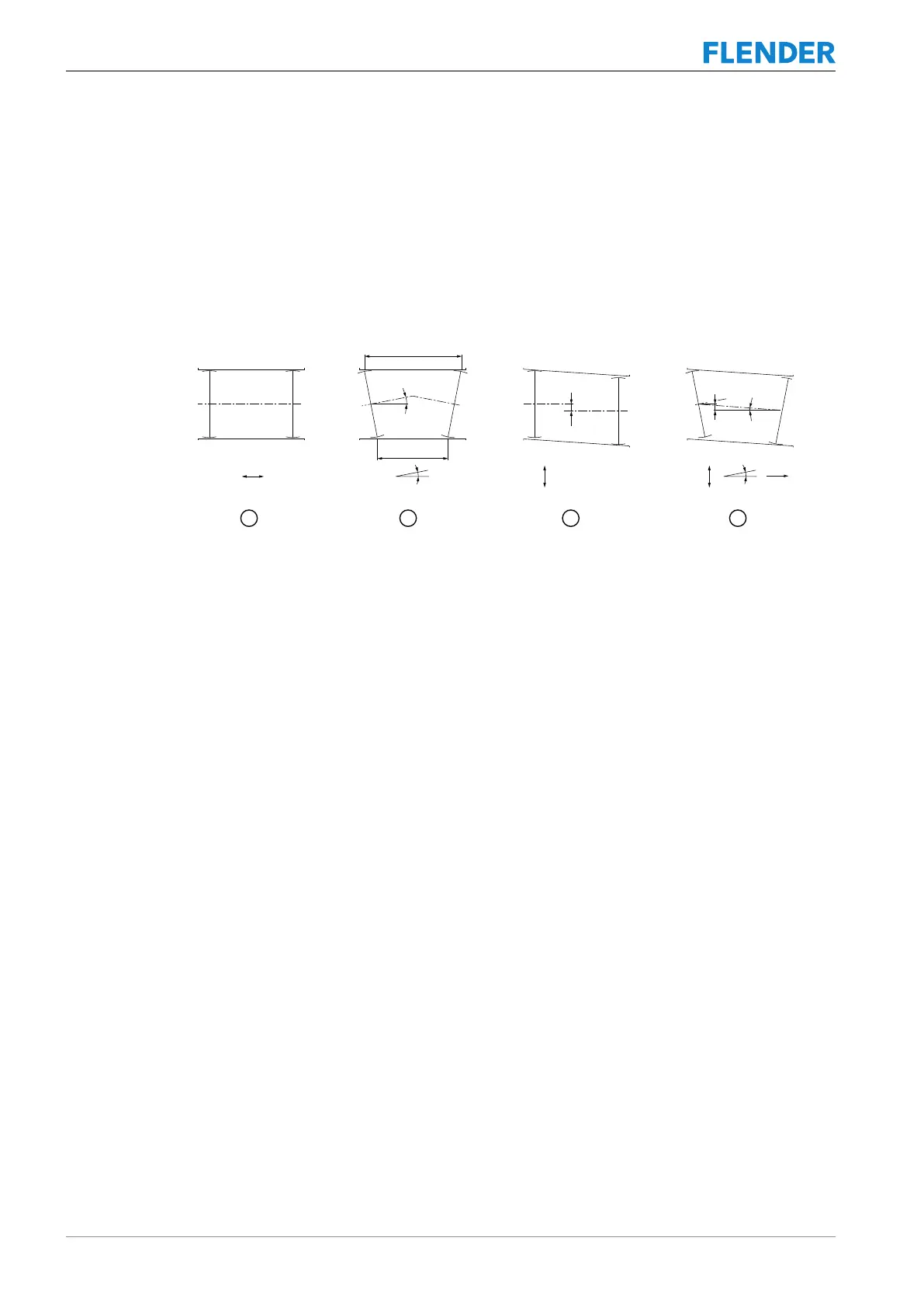

5.3.2 Possible misalignment5.3 Aligning the coupling

The following types of misalignment can occur:

ǡ,B4

NBY

4

NJO

ǡ,B

4

NBY

ǡ,X

ǡ44

NBY

4

NJO

4

NJO

ǡ,S

Figure5-4:Possible misalignment

① Axial misalignment (ΔKa)

② Angular misalignment (ΔKw)

③ Radial misalignment (ΔKr)

④ Axial, angular and radial misalignment

5.3.2.1 Axial misalignment5.3 Aligning the coupling

Set the axial misalignment ΔKa to a value within the permissible tolerance range for the S

clearance.

The values for the S clearance are to be considered as the maximum permissible increase in

the hub distance of the coupling.

You can find the values for clearance S under Clearance S (Page66).

5.3.2.2 Angular misalignment5.3 Aligning the coupling

The ZNN, ZNNV, ZNZS and ZNZV types compensate for positional deviations of the shaft

ends to be connected up to a maximum angular misalignment of ΔKw=0.5°.

The ZNNA and ZNZA types compensate for positional deviations of the shaft ends to be con-

nected up to a maximum angular misalignment of ΔKw=0.2°.

Determine the value ΔS (ΔS = S

max

- S

min

).

ZNN, ZNNV, ZNZS, ZNZV types:

ΔS = S

max

- S

min

≤ ND x tan 0.5° ≈ ND / 100

ZNNA, ZNZA types:

ΔS = S

max

- S

min

≤ ND x tan 0.2° ≈ ND / 300

Loading...

Loading...