Assembly

5.1 Preparatory work

M3560-02en Edition 09/2022 29

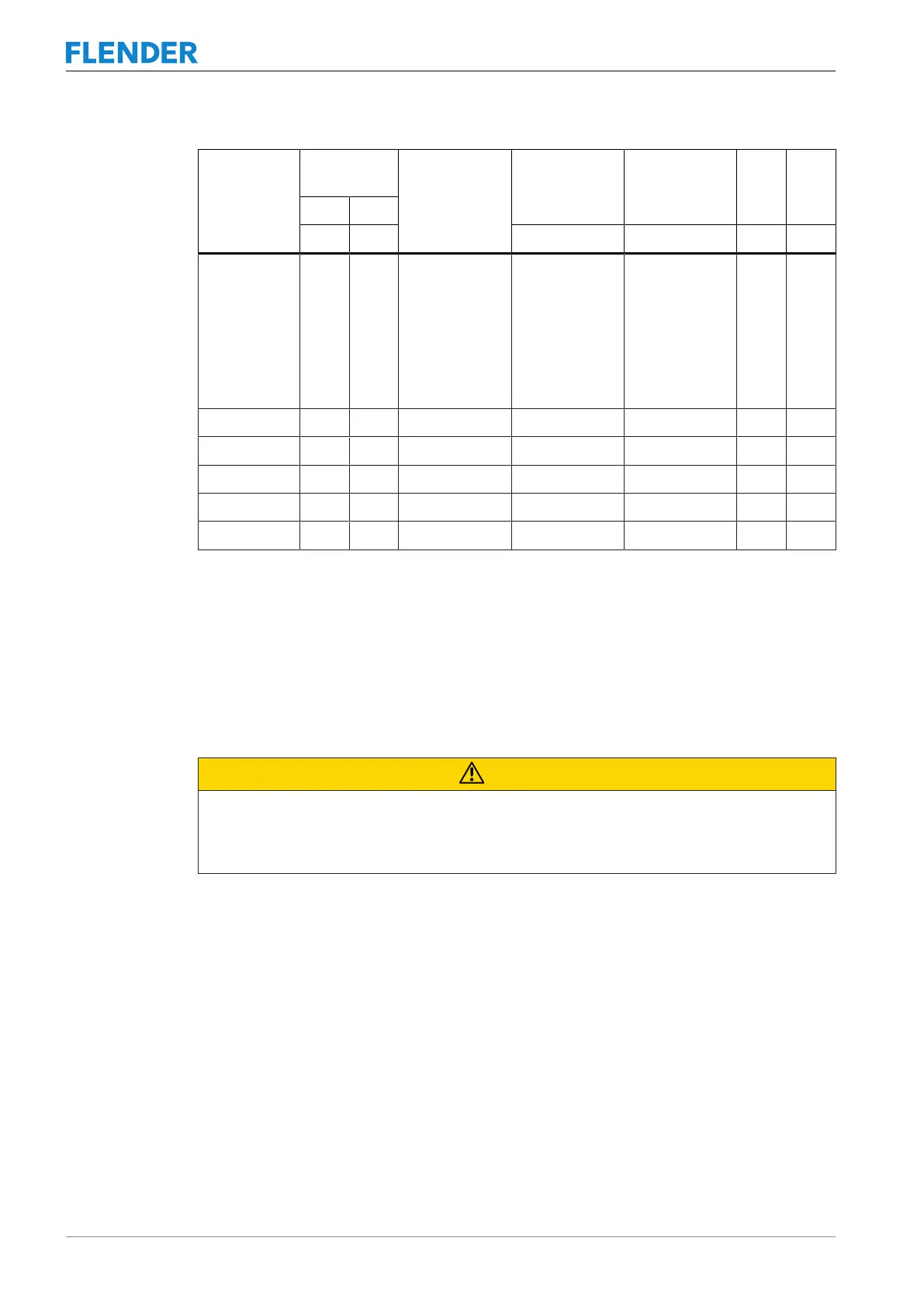

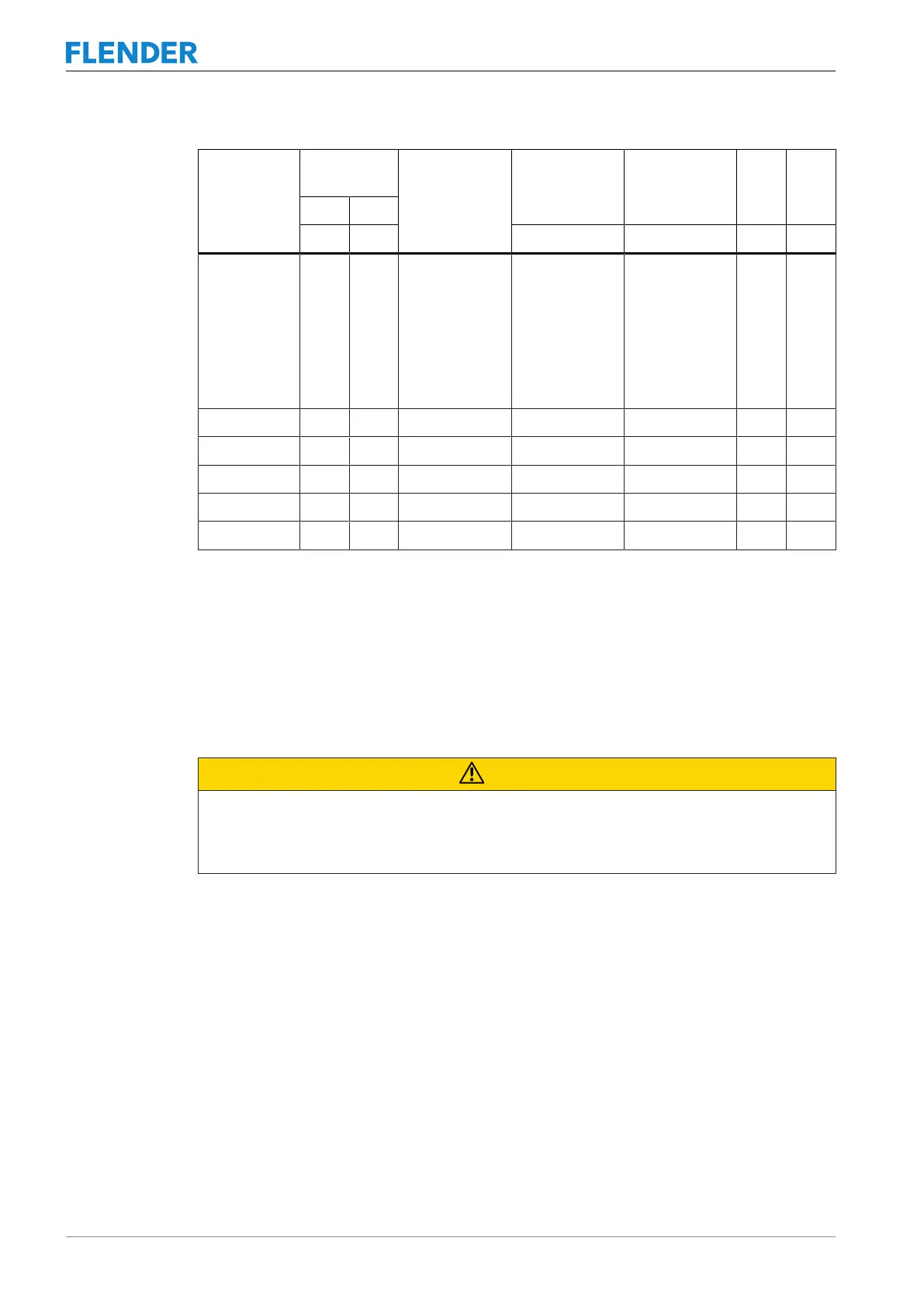

Coupling size Finished

bore D

Threaded hole

d1

Tightening

torque TA

Width A/F in-

ternal hexagon

e1 e2

Over Up to

mm mm Nm mm mm mm

250 10

17

22

30

38

50

17

22

30

38

50

164

M5

M6

M8

M10

M12

M16

3

4

8

15

25

70

2.5

3

4

5

6

8

22 40

274 80 178 M16 70 8 25 46

307 90 198 M16 70 8 30 54

333 100 216 M16 70 8 30 61

364 120 242 M20 130 10 30 50

424 150 288 M24 230 12 30 50

Table5-2: Diameter and axial position of the threaded hole, tightening torque and width A/F

Apply the specified tightening torques as listed in Section Tightening procedure (Page69).

Position of the threaded hole with respect to the parallel keyway

Position the threaded hole for the set screw on the parallel keyway.

Selection of the set screw

CAUTION

Physical injury

Risk of injury from protruding set screw.

• Please observe the information about selecting the set screw.

Use set screws in accordance with ISO 4029 with a toothed cup point. The size of the set

screw is determined by the bore made. The set screw should fill out the threaded hole as

much as possible and must not protrude beyond the hub.

Loading...

Loading...