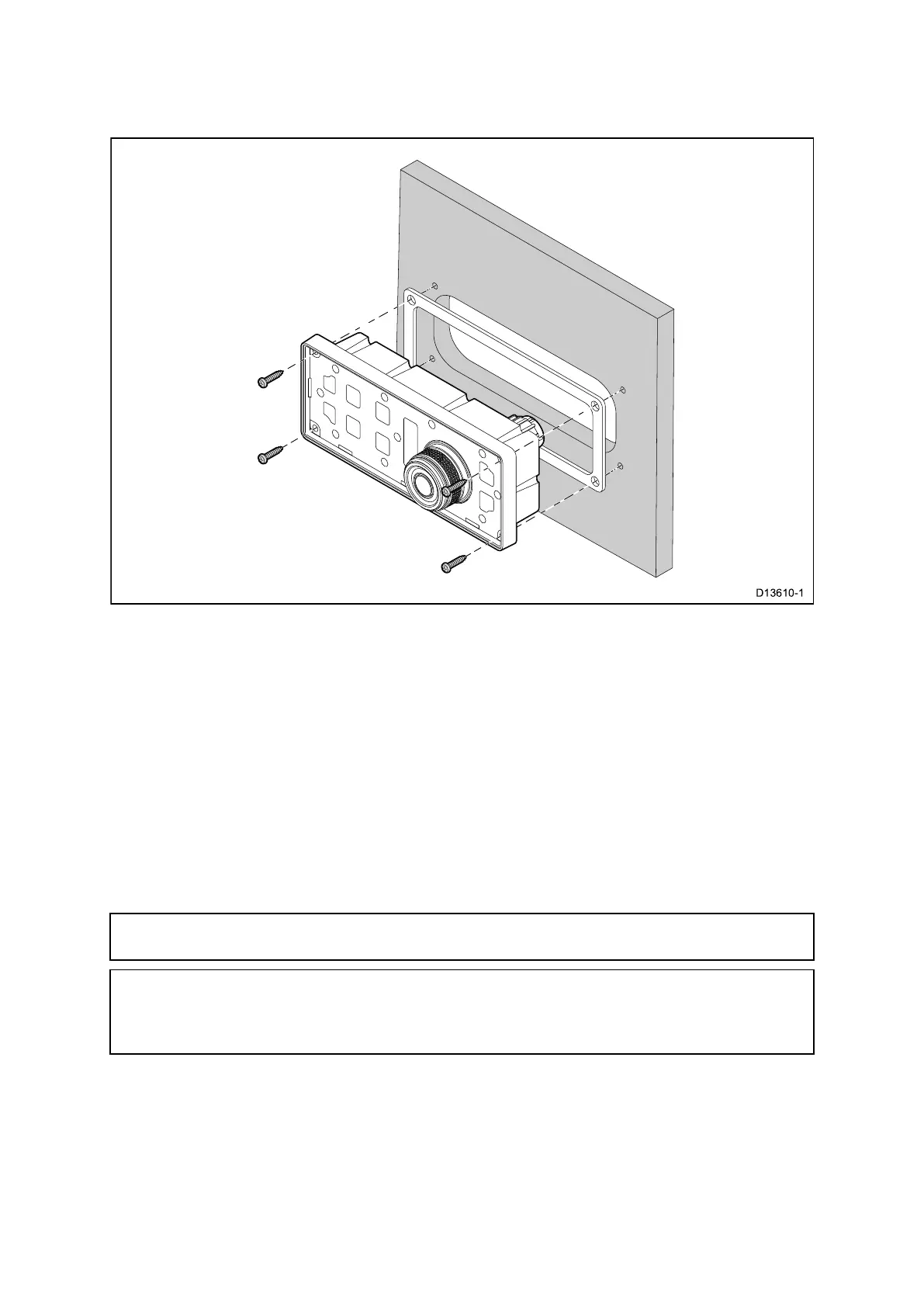

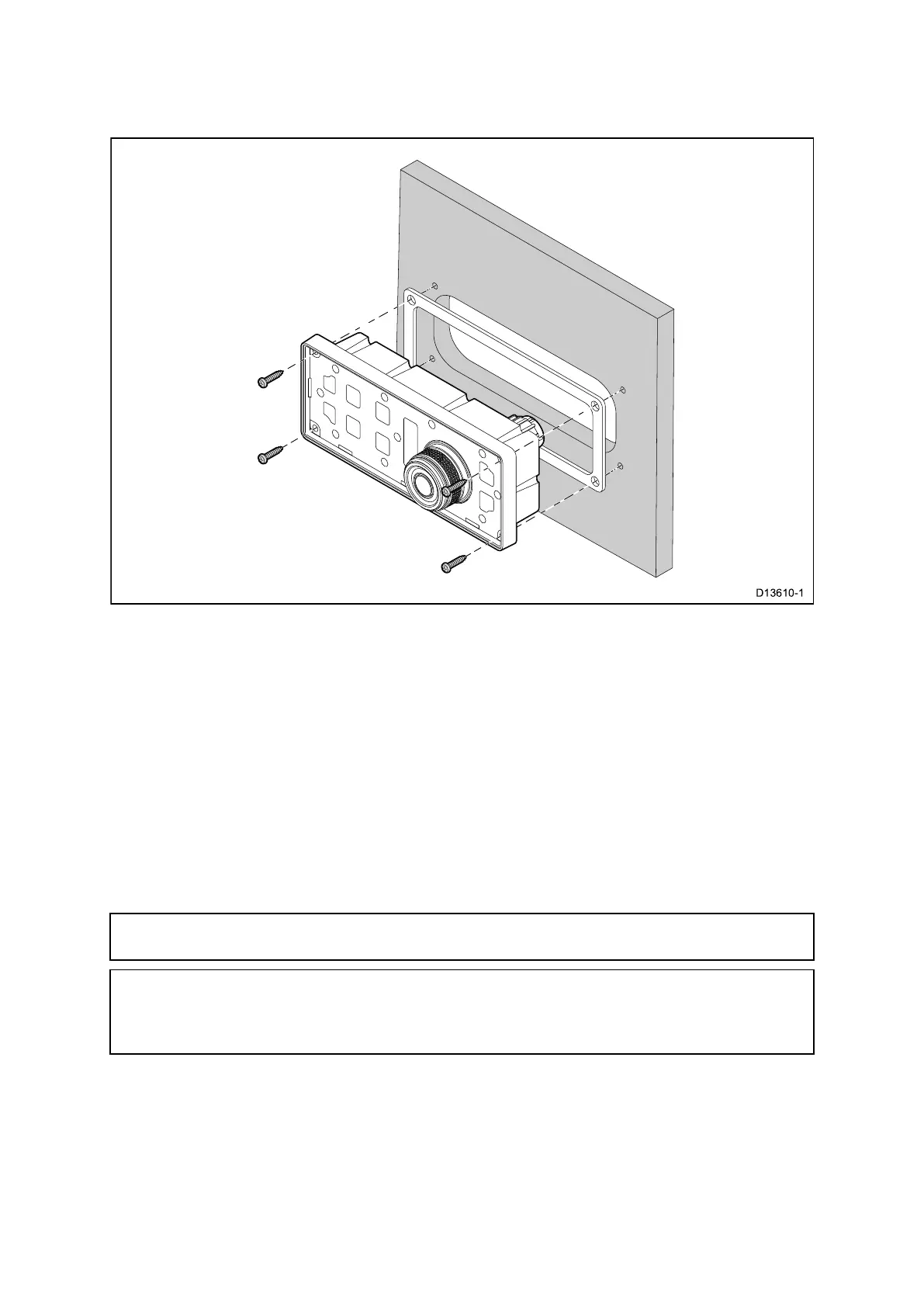

Surfacemountingthekeypad

Surfacemountingprovidesauniforminstallationwheretheproductsprotrude,usuallyby

thethicknessofthebezel,fromthemountingsurface.

1.Checktheselectedlocationfortheunit.Aclear,atareawithsuitableclearance

behindthepanelisrequired.

2.Beforemodifyingthemountingsurface,refertothedimensionssuppliedinthis

documenttoensurethereisenoughspacefortheunitandallcables.

3.Fixthesuppliedmountingtemplatetotheselectedlocation,usingmaskingorself

adhesivetape.

4.Drill4holesasindicatedonthemountingtemplatetoacceptthexings.

5.Usingasuitableholesaw,makeaholeineachcornerofthecut-outarea.

6.Usingasuitablesaw,cutalongtheinsideedgeofthecut-outline.

7.Ensurethattheunittsintotheremovedareaandthenremoveroughedges.

8.Placethesuppliedgasketontotherearofthekeypad,ensuringthemounting

holesarealigned.

9.Connecttherelevantcablestotheunit.

10.Secureusingthexingsprovided.

Note:Theappropriatetighteningtorqueanddrillbitsizetousedependsonthe

thicknessofthemountingsurfaceandthetypeofmaterialitismadefrom.

Note:Thesuppliedgasketprovidesasealbetweentheunitandasuitablyatand

stiffmountingsurfaceorbinnacle.Thegasketshouldbeusedinallinstallations.It

mayalsobenecessarytouseamarine-gradesealantifthemountingsurfaceor

binnacleisnotentirelyatandstifforhasaroughsurfacenish.

Fittingthekeypadmat

Y ourkeypadcanbeinstalledinportraitorlandscapeorientation.keypadmatsare

availableforeachorientation.

•Y oushouldtthekeypadmatthatmatchesyourchosenmountingorientation.

•Y oushouldonlytthekeypadmataftertheunithasbeensecuredtothemounting

surface.

1.Ensurethekeypadmatisorientatedcorrectly.

Mounting

61

Loading...

Loading...