5700A/5720A Series II Calibrator

Service Manual

5-60

Note

The duty cycle may differ from this figure. Using the Calibrator edit knob,

vary the second LSD of the Calibrator output display and verify that the

duty cycle of the signal at TP7 changes. If either of these displayed signals

are incorrect, skip to Duty Cycle Control Circuit.

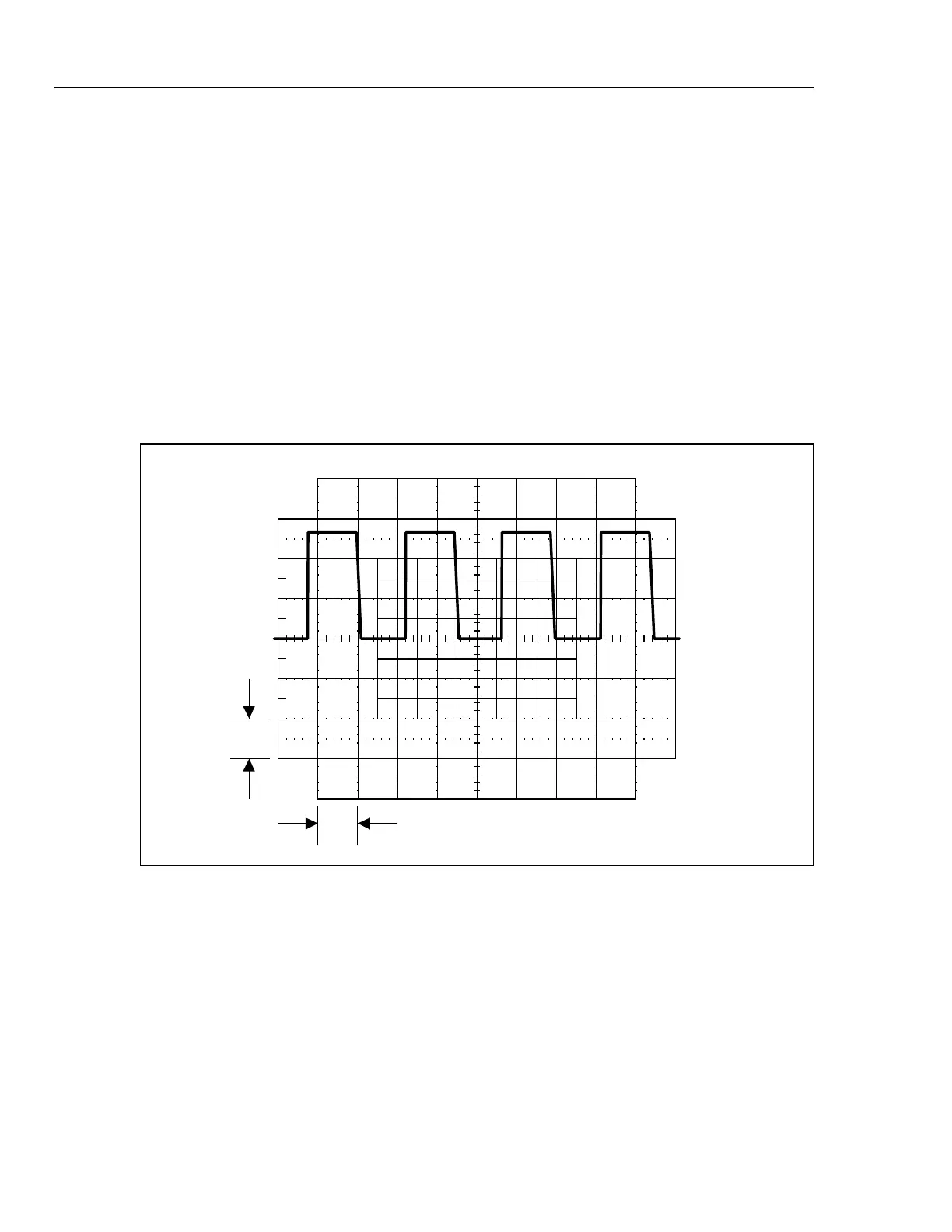

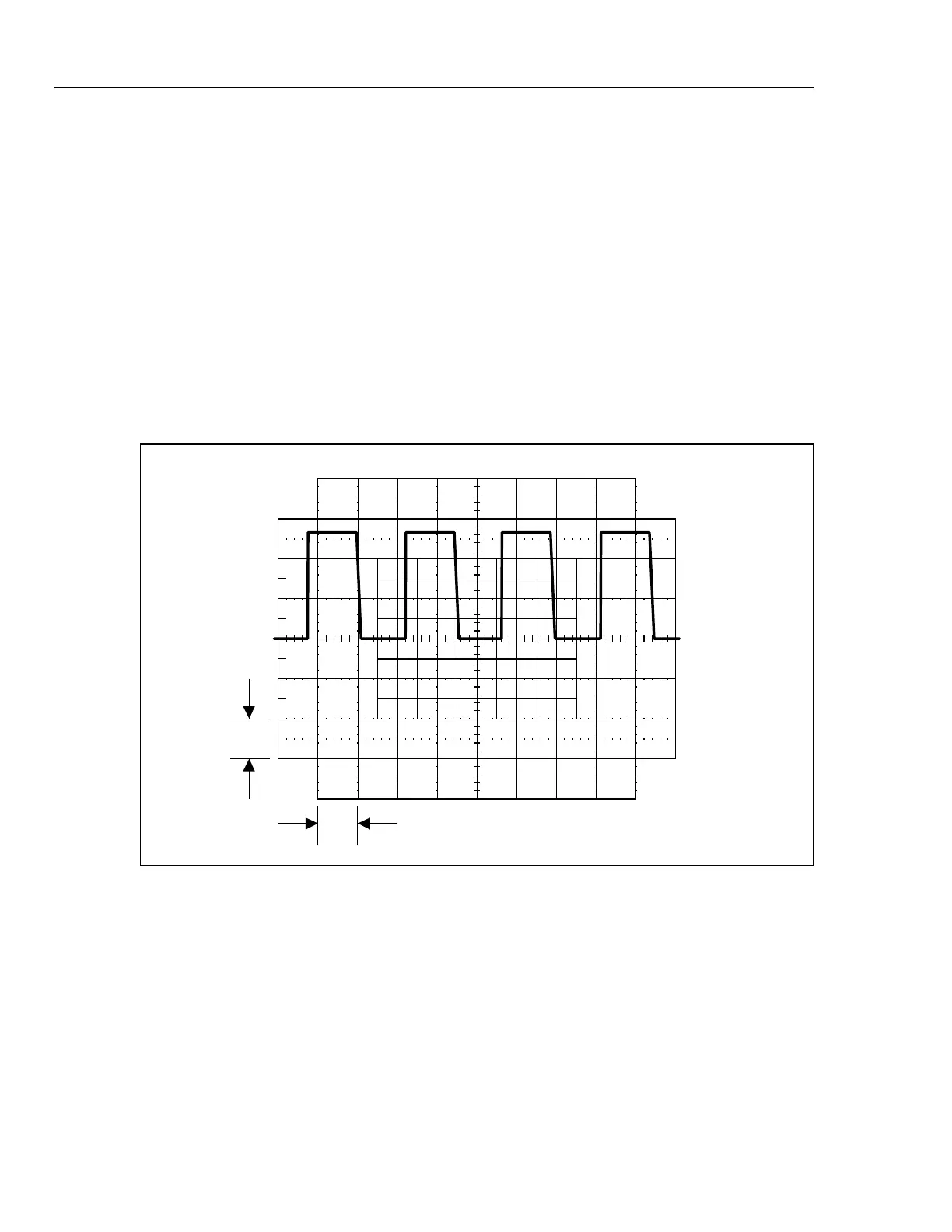

6. Check the SERIES LINEARITY CONTROL CIRCUIT. Using a DMM measure the

voltage at U38 pin 6 (common to TP3). The voltage should be +23.0 to +26.4V. If

this voltage is incorrect, check U38 and Z2.

7. Check the NEG. OFFSET CIRCUIT. Using a DMM measure the voltage at U2 pin 1

(common to TP3). The voltage should be -13 to -14V which is the reference voltage

inverted. If this voltage is incorrect, check U2A and part of the HR6 resistor network.

8. Connect an oscilloscope to TP5 (common to TP3), and set the Calibrator to 6.5V dc,

operate. Set the oscilloscope to 5V/div at 2 ms/div and verify the signal is similar to

that shown in Figure 5-21. If this signal is incorrect, check Q4, Q5, Q6, and Q7.

1 V

10 ms

F5-21.EPS

Figure 5-21. Waveform at TP5

9. Check the FILTER INPUT. Set the Calibrator to 6.5V dc, operate. Measure the

voltage with a DMM at TP1 (common to TP3 on the main board) on the DAC Filter

SIP assembly (A11A1). It should be a nominal +6.5V dc(±0.1V for an uncalibrated

instrument), free of distortion, and stable. If a failure is detected, check the DAC

Filter SIP assembly.

10. Check the DC AMP HYBRID. Set the Calibrator to 10V dc, operate. Measure the

voltage with a DMM at pin 18 (common to TP3) of the HR6 DC AMP HYBRID. It

should be a nominal +10V dc (±0.25V for an uncalibrated instrument), free of

distortion, and stable. If a failure is detected, check the HR6 Hybrid assembly and its

heater control circuit.

Loading...

Loading...