RXB PLUS ROTARY SCREW COMPRESSOR UNITS S70-101 IOM

Page 55

58

5

70

69

68

67

66

65

64

63

62

61

60

59

57

56

55

53

54

52

51

50

49

48

46

47

45

43

44

42

41

5

40

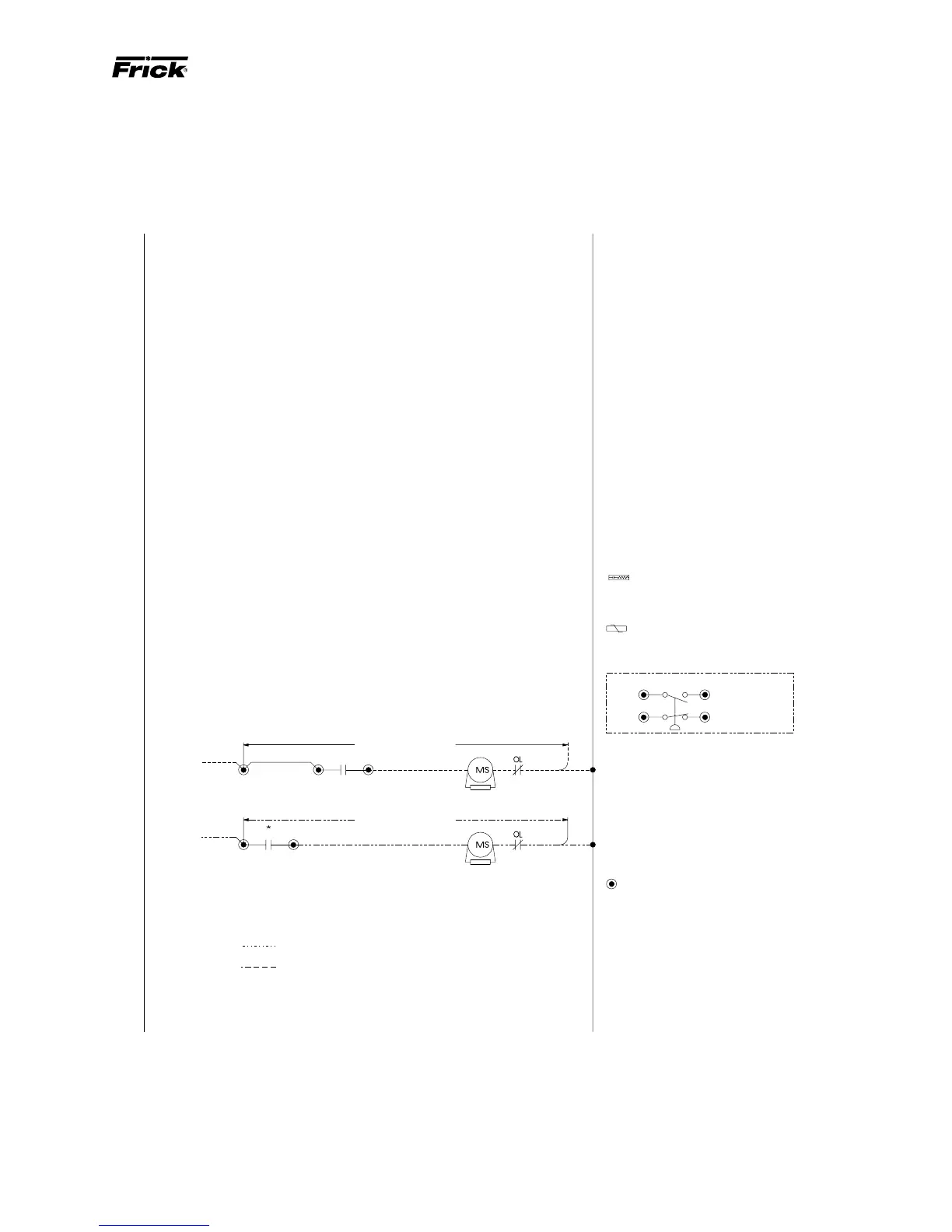

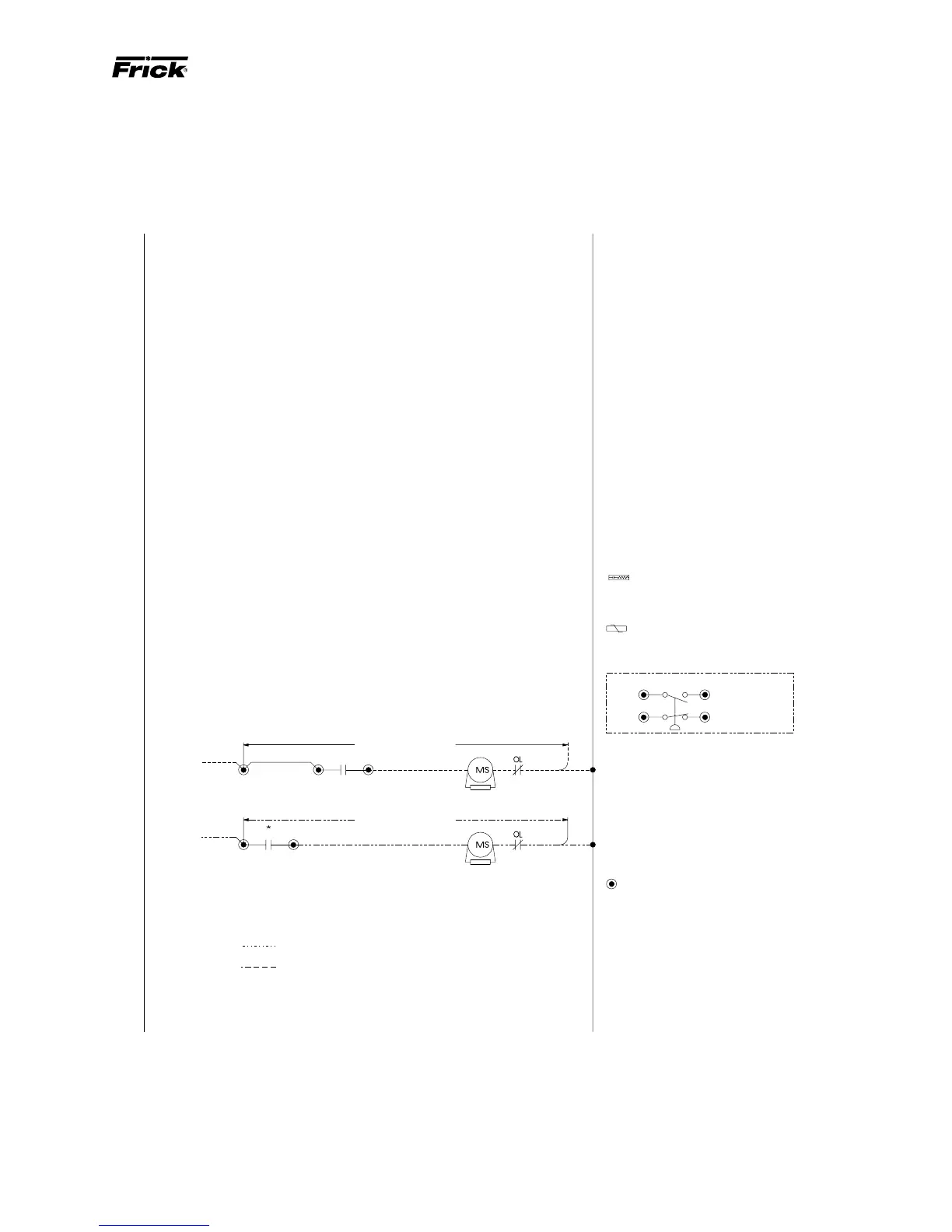

2CR

(Y)

(Y)

(Y)

(Y)

(Y)

8

37

HOT

3CR

JUMPER

SEE NOTE B

36

HOT

42

WIRING IF ISOLATED

2CR CONTACT IS USED

SEE NOTE A

WIRING IF ISOLATED

3CR CONTACT IS USED

SEE NOTE A

18

2

NEU

NEU

36

30

42

2

1 PSH WIRING FOR GAUGEBOARD OPTION

HPCO

5

PROGRAM

AUX 1 AS

NOR. CLOSED

SHUTDOWN

1-PSH

NOTE A:

IF COMPR. MOTOR STARTER IS A FRICK SUPPLIED STARTER

OR CONFORMS TO FRICK STARTER SPECS,WIRE AS SHOWN

ON LINE 60 ONLY. JUMP TERM 6 TO 36.

IF 2CR IS USED AS A ISOLATED CONTACT,WIRE AS SHOWN

BETWEENTHE HOT & NEUTRAL LINES ON LINE 60.

NOTE C:

A SURGE SUPPRESSOR OR MOV TO BE INSTALLED ACROSS

ALL INDUCTIVE LOADS IN CONTROL CENTER.

SURGE SUPPRESSOR

VARISTOR

METAL OXIDE VARISTOR (MOV) SPECIFICATIONS:

GE #V130LA10A OR EQUAL

COMPR MOTOR STARTER

IF STARTER CONTAINS MULTIPLE

CONTACTORS, RELAYS, & TIMERS,

ADD SUPRESSORS OR VARISTORS

AT EACH COIL (SEE NOTE C)

OIL PUMP STARTER

SUPRESSOR OR VARISTOR

INSTALLED AT OIL

PUMP STARTER COIL

(SEE NOTE C)

TERMINALS IN CONTROL CENTER

* INDICATES FURNISHED OR REQUIRED WITH OIL PUMP ONLY

INDICATES DEVICES SUPPLIED ONLY

WHEN OPTIONAL OR REQUIRED

JUMP TO 6

IF REQ'D

SEE NOTE A

JUMP TO 6

IF REQ'D

SEE NOTE A

WIRING BY OTHERS- ALL WIRING ENTERING CONTROL

CENTER (INCLUDING GROUND & NEUTRAL) TO BE #14

AWG STRANDED WIRES UNLESS SPECIFIED OTHERWISE.

FOR HIGH POT TEST PROCEDURE, SEE MMIB NO. 4.11.10.7

SEE 640D0024 FOR STANDARD CONTROL CENTER ASSEMBLY

FOR INSTALLATION OF MICROPROCESSOR BOARD

AND EPROMS, SEE MMIB NO. 4.11.10.11

FOR RXB PACKAGE/MICROPROSSOR TEST PROCEDURE,

SEE MMIB NO. 4.11.10.8

ALL CONTROL CENTER WIRING TO BE #16 AWG

STRANDED WIRE UNLESS SPECIFIED OTHERWISE.

NO THREE PHASE WIRING SHALL ENTER OR LEAVE MICRO PANEL

NO SINGLE PHASE OVER 300 VOLTS SHALL ENTER OR LEAVE

MICRO PANEL

FOR PROPER INSTALLATION OF ELECTRONIC EQUIPMENT,

SEE FRICK PUBLICATION S90-400 SB/ SERVICE MANUAL.

SUPPRESSOR SPECIFICATIONS:

RC NETWORK CONSISTING OF A .1 MFD CAPACITOR, 600

VDC IN SERIES WITH A 47 OHM RESISTOR.

USE ELECTROCUBE #RG2031-3-6 OR EQUAL.

IF 2CR IS USED AS A ISOLATED CONTACT, WIRE AS SHOWN

BETWEEN THE HOT & NEUTRAL LINES ON LINE 60.

SAME NOTES APPLY TO OIL PUMP STARTER CIRCUIT

ON LINE 63.

NOTE B:

FOR OPTIONAL ALARMS & SHUTDOWNS:

(HIGH LEVEL SHUTDOWN ETC.)

WHEN REFERENCING MICRO POWER TO OPERATE COMPR.

WHEN USING 2CR AS A ISOLATED CONTACT (PARAGRAPH 2,

NOTE A), REMOVE JUMPER 36 TO 42 & INSERT ISOLATED

CONTACT(S). A SEPARATE ISOLATED CONTACT SHOULD BE

INSERTED BETWEEN 5 & 29 OR 30. PROGRAM AUX AS

ABOVE. SEE 1-PSH WIRING BELOW FOR EXAMPLE.

AUX 1 & AUX 2 CAN BE PROGRAMMED TO ALARM OR

SHUTDOWN, NOR. OPEN OR NOR. CLOSED.

MOTOR STARTER (PARAGRAPH 1-NOTE A), REMOVE JUMPER

36 TO 42 & INSERT ISOLATED CONTACT(S). JUMP 42 TO

EITHER 29 OR 30 (AUX 1 OR AUX 2). PROGRAM AUX TO

SHUTDOWN-NORMALLY CLOSED.

RXBELD2

MICRO PANEL ASSEMBLY WIRING DIAGRAM

MAINTENANCE

Loading...

Loading...