RXB PLUS ROTARY SCREW COMPRESSOR UNITSS70-101 IOM

Page 56

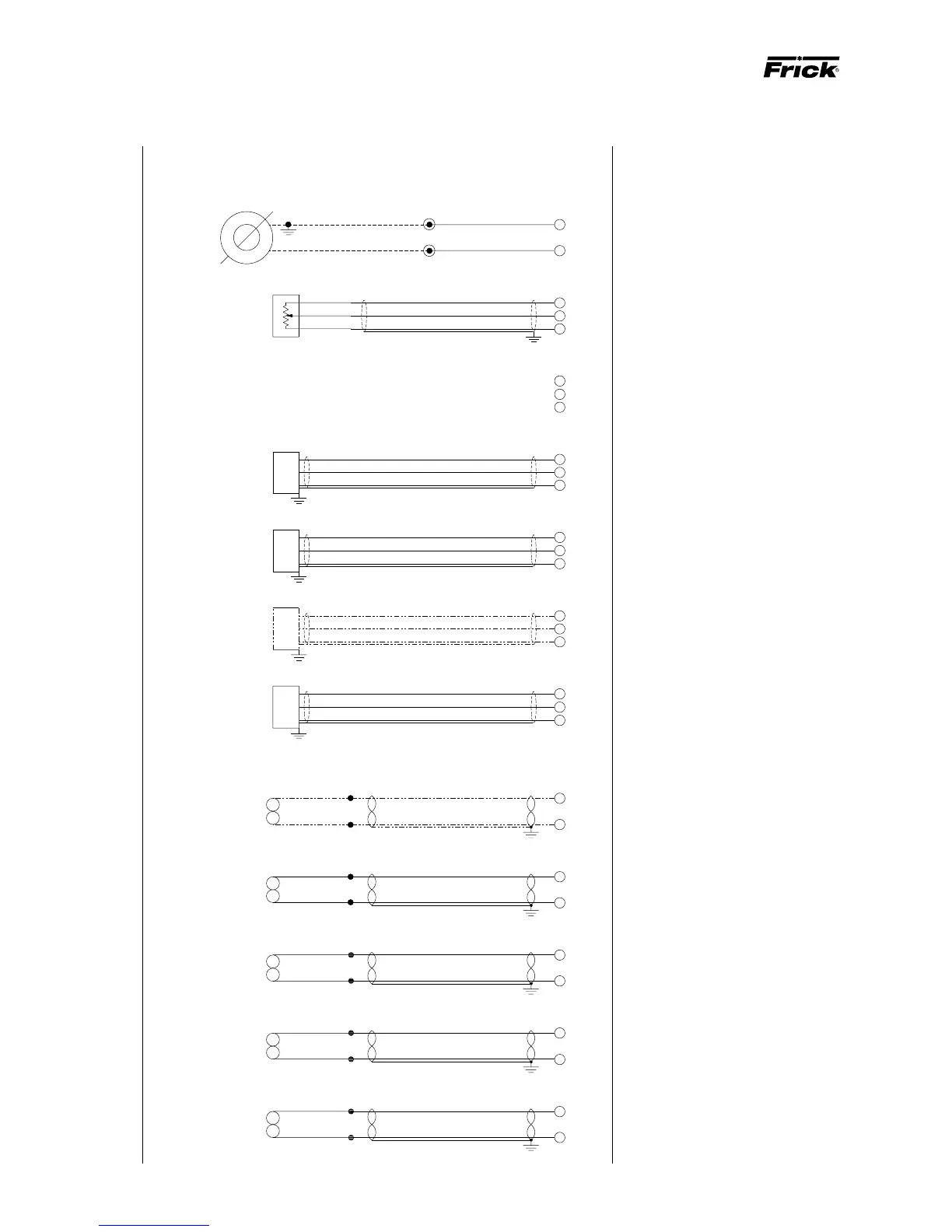

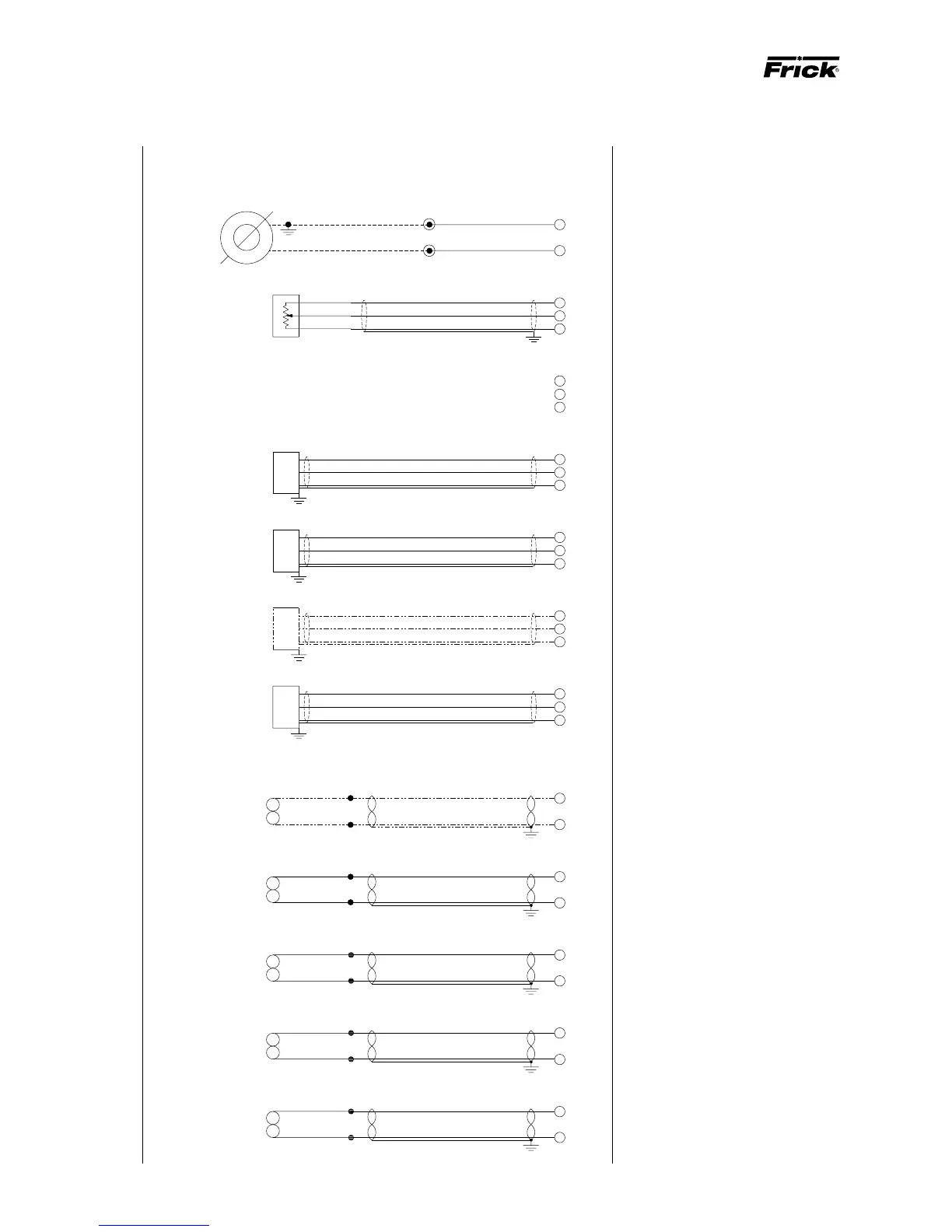

MICRO PANEL ASSEMBLY WIRING DIAGRAM

MAINTENANCE

19

#20 AWG TWISTED PAIR

2000 FT. MAX. DISTANCE

38

39

5

37

36

35

34

33

TE-1

BLACK

TE-2

BLACK

BLACK

32

31

30

29

28

27

26

TE-3

BLACK

COLOR MAY VARY

TYPICAL

TE-4

BLACK

25

24

23

22

21

20

TE-5

PE-4

PE-1

PE-2

PE-3

RED

WHITE

BLACK

WHITE

WHITE

CABLE #1

CABLE #2

BLACK

2

BLACK

BLACK

WHITE

WHITE

CABLE #3

CABLE #4

BLACK

BLACK

WHITE

CABLE #6

CABLE #5

CABLE #7

12

18

17

16

15

14

13

RED

WHITE

BLACK

BLACK

WHITE

RED

WHITE

BLACK

POTENTIOMETER

POSITION

SLIDE VALVE

10

11

09

07

08

06

RED

2

1

3

RED

WHITE

BLACK

C.T. MOUNTED IN STARTER OR

MOTOR JUNCT. BOX (BY OTHERS)

05

04

03

02

01

AMPS

ONE PHASE

OF MOTOR

MOTOR

5

SECONDARY

0-5 AMP AC

CABLE #8

CABLE #9

DO NOT GROUND PE DRAIN AT PANELCABLE

TYPICAL

CABLE #11

3

4

2

CHANNEL 12

0-5 AMP AC

MOTOR AMPS

(CHANNEL 11)

SLIDE VALVE

(CHANNEL 10)

1-5 VDC

ECON PRESS

(CHANNEL 9)

1-5 VDC

SUCT PRESS

(CHANNEL 8)

1-5 VDC

DISCH PRESS

(CHANNEL 7)

1-5 VDC

FILTER PRESS

(IF OPTIONAL OR REQ'D)

(CHANNEL 6)

1-5 VDC

OIL PRESS

(CHANNEL 5)

SPARE TEMP

REMOTE TEMPERATURE

CAPACITY CONTROL (OPTIONAL)

WIRING BY OTHERS

SEE NOTE 2A

(CHANNEL 4)

SEP TEMP

(CHANNEL 3)

OIL TEMP

(CHANNEL 2)

DISCH TEMP

(CHANNEL 1)

SUCT TEMP

SEE IOM MANUAL

FOR C.T.WIRE SIZING

R

R

R

S

S

S

S

S

S

S

S

S

+

+

+

+

+

+

+

+

+

+

+

+

+

+

_

_

_

_

_

_

_

_

_

_

_

_

_

_

B

W

RXBELD3

Loading...

Loading...