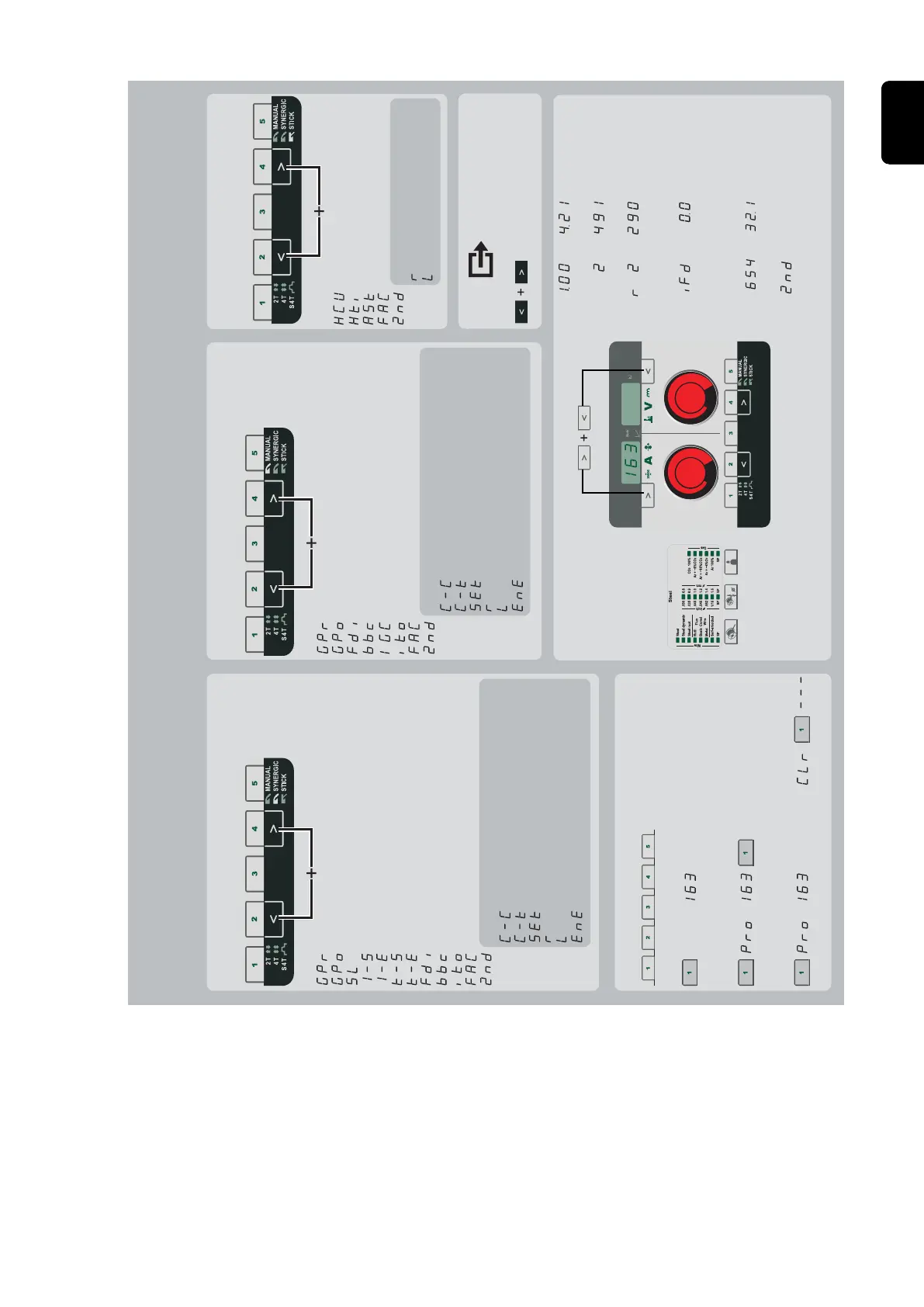

Gas pre-fl ow time

Gas post-fl ow time

Threading speed

Burn-back effect

Ignition current

Length of wire before the safety cut-out trips

Restoring factory setup

2nd menu level

Cooling unit control

Cooling unit watchdog

Country setting

Welding circuit resistance

Welding circuit inductivity

Real Energy Input

MIG/MAG - setup

Manual

Display service parameters

Operating points

briefl y press

retrieve:

press and hold down for several seconds release

delete:

save:

Welding circuit resistance

Welding circuit inductivity

Gas pre-fl ow time

Gas post-fl ow time

Slope (2-step, special 4-step)

Starting current (2-step, special 4-step)

Final current (2-step, special 4-step)

Starting current duration (2-step)

Final current duration (2-step)

Threading speed

Burn-back effect

Length of wire before the safety cut-out trips

Restoring factory setup

2nd menu level

Cooling unit control

Cooling unit watchdog

Country setting

Welding circuit resistance

Welding circuit inductivity

Real Energy Input

MIG/MAG - setup

Synergic

Hot-start current

Hot-current time

Anti-stick

Restoring factory setup

2nd menu level

Rod electrode - setup

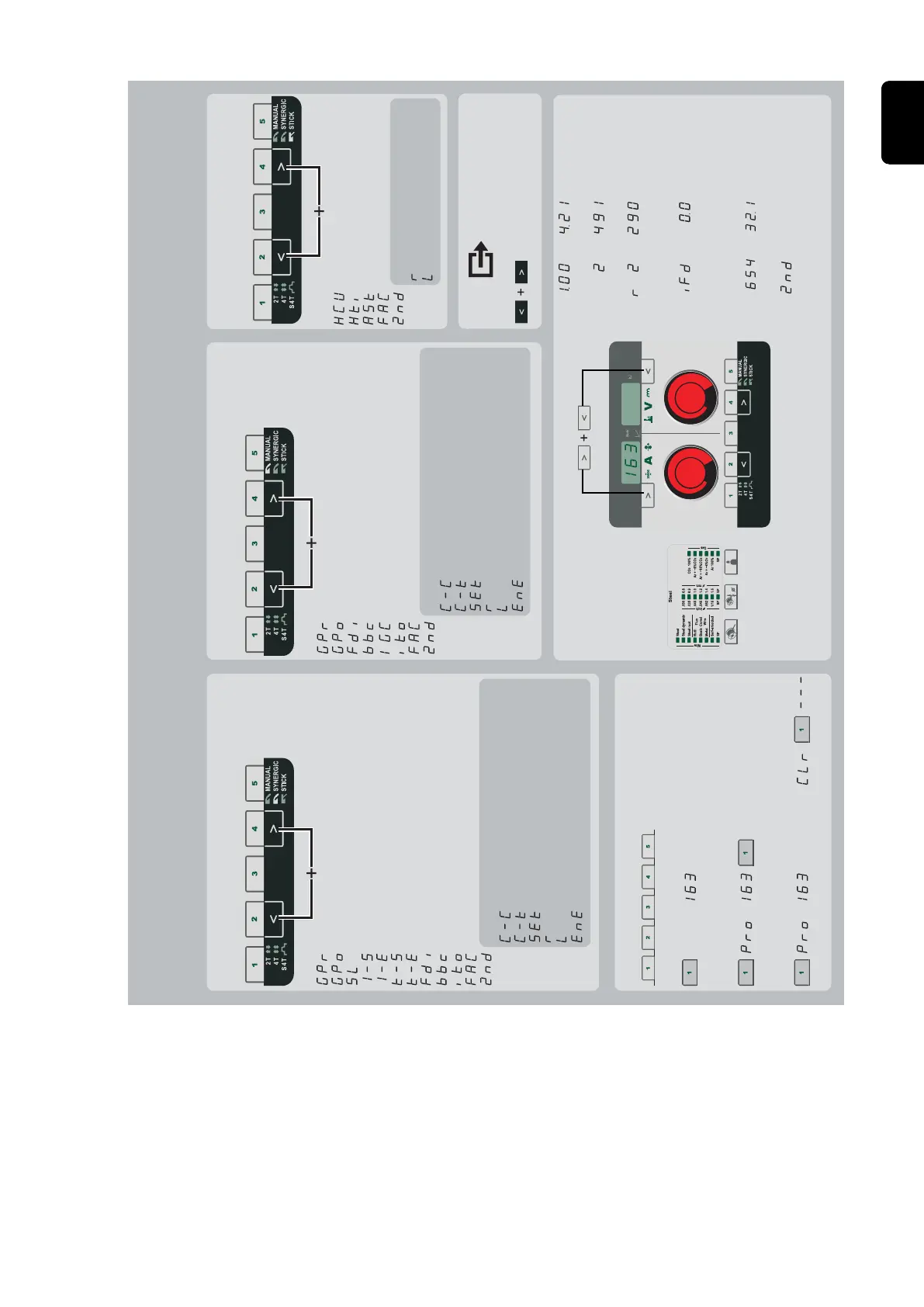

Quick Reference: English

TransSteel Synergic

press and hold

release

5 „Save“ buttons

Setup

2. Menu level for service engineers

e.g.:

e.g.:

e.g.:

e.g.:

e.g.:

fi rmware version

welding program confi guration

number of the currently selected welding

program

motor current for wire drive in A

The value changes as soon as the motor

is running.

Arc burning time

Loading...

Loading...