CHAPTER 6: SETPOINTS S3 PROTECTION

339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL 6–35

Total Capacity Used

register (TCU)

339 thermal protection integrates stator and rotor heating into one model. The rate of

motor heating is gauged primarily by measuring the terminal currents. The present value

of the accumulated motor heating is maintained in the Thermal Capacity Used actual

value register.

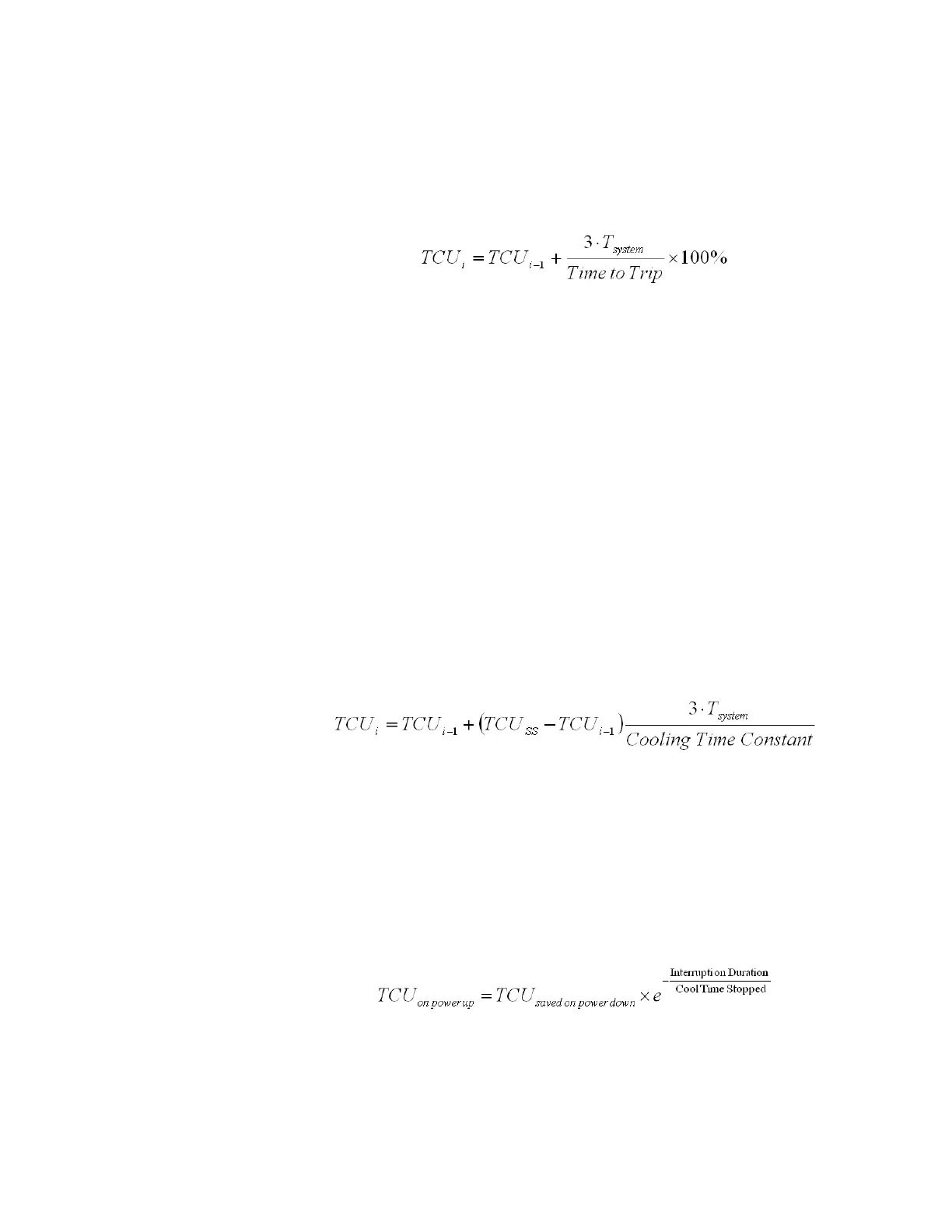

While the motor’s equivalent current is greater than the thermal overload pickup setting,

the TCU register is updated every 3 cycles using the following equation:

Eq. 1

where:

Time to Trip = Thermal Overload Trip Time in seconds, calculated from the thermal

overload curve when running, or from the start protection when starting. The thermal

overload curve and the start protection are described in the corresponding sections below.

T

system

= the period in seconds corresponding to the nominal power system frequency.

The 339 thermal protection addresses the two distinct parts of the thermal limit curve: the

motor starting limit, and the running limit. The start protection determines Time to Trip

during motor starting, and the thermal overload curve determines Time to Trip during

motor running.

When the motor is in overload, the motor’s temperature and the Thermal Capacity Used

will be rising. When the thermal capacity used reaches 100%, a trip will occur. The thermal

overload curve and start protection should always be set slightly lower than the thermal

limits provided by the manufacturer. This will ensure that the motor is tripped before the

thermal limit is reached.

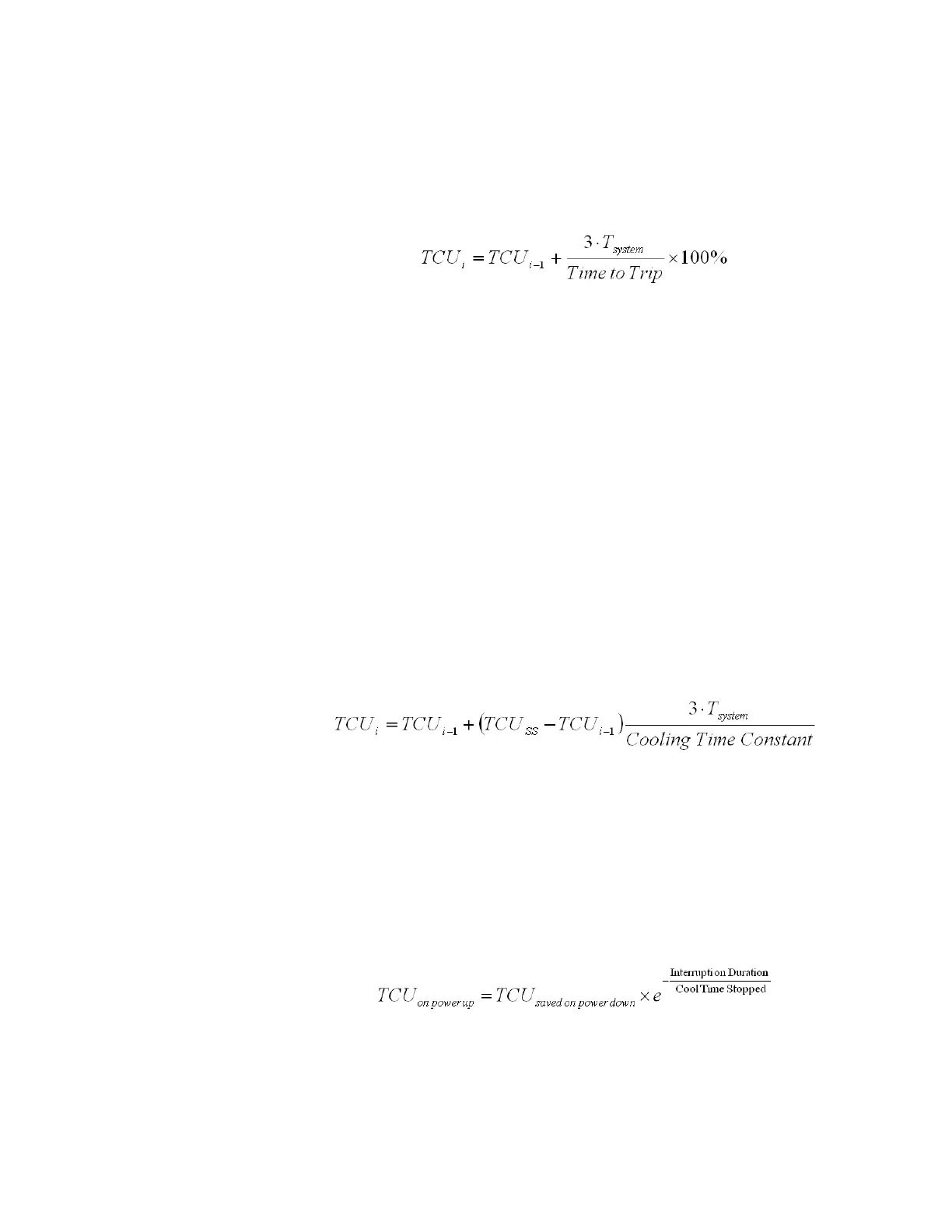

When the motor is stopped and is cooling to ambient, the Thermal Capacity Used decays

to zero. If the motor is running normally, the motor temperature will eventually stabilize at

some steady state temperature, and the Thermal Capacity Used moves up or down to

some corresponding intermediate value TCU

SS

, which accounts for the reduced amount of

thermal capacity left to accommodate transient overloads. While the motor’s equivalent

current is less than the thermal overload pickup setting, the TCU register is updated every

3 cycles using the following equation:

Eq. 2

where:

TCU

SS

= Steady state TCU corresponding to the running terminal current; zero when

stopped, or when running as described in the hot/cold biasing section below.

Cooling Time Constant = The value of the Cool Time Running setting when running, or the

value of the Cool Time Stopped setting when stopped, expressed in seconds.

T

system

= the period in seconds corresponding to the nominal power system frequency

The TCU register value can also be forced to at least equal the RTD bias value as described

in the RTD Biasing section below.

In the event of a loss of control power to the relay, the thermal capacity will decay for the

duration of the loss of control power based on the stopped motor cooling rate.

Eq. 3

Loading...

Loading...