CHAPTER 6: SETPOINTS S3 PROTECTION

339 MOTOR PROTECTION SYSTEM – INSTRUCTION MANUAL 6–43

TCU

used_start

: the TCU caused by an overload condition

TCU

used_end

: the TCU dictated by the hot/cold safe stall ratio when the motor is

running (=0 when the motor is stopped)

t: time in minutes

τ: Cool Time Constant (running or stopped)

I

eq

: equivalent motor heating current

O/L

_PKP

: overload pickup setting as a multiple of FLA

HCR: hot/cold safe stall ratio

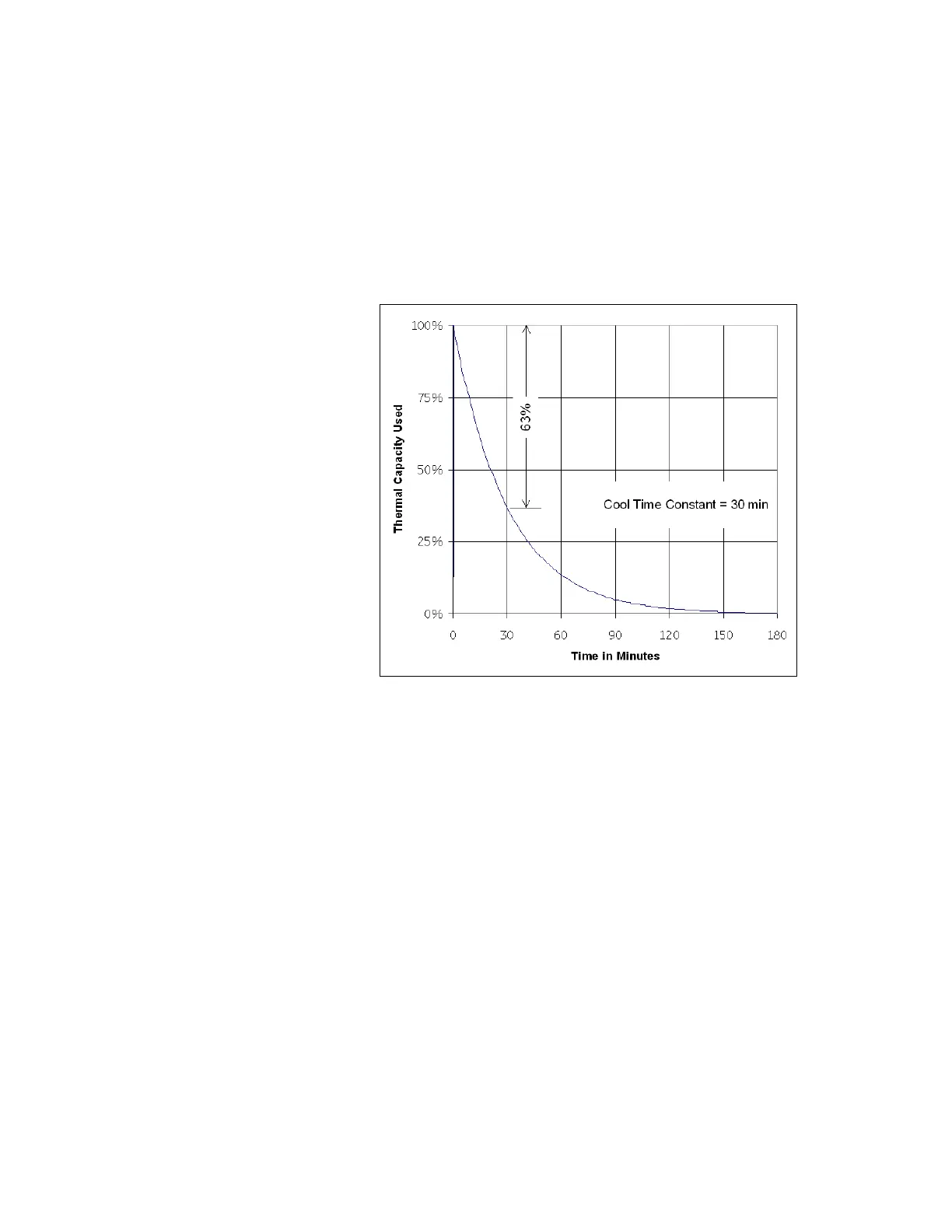

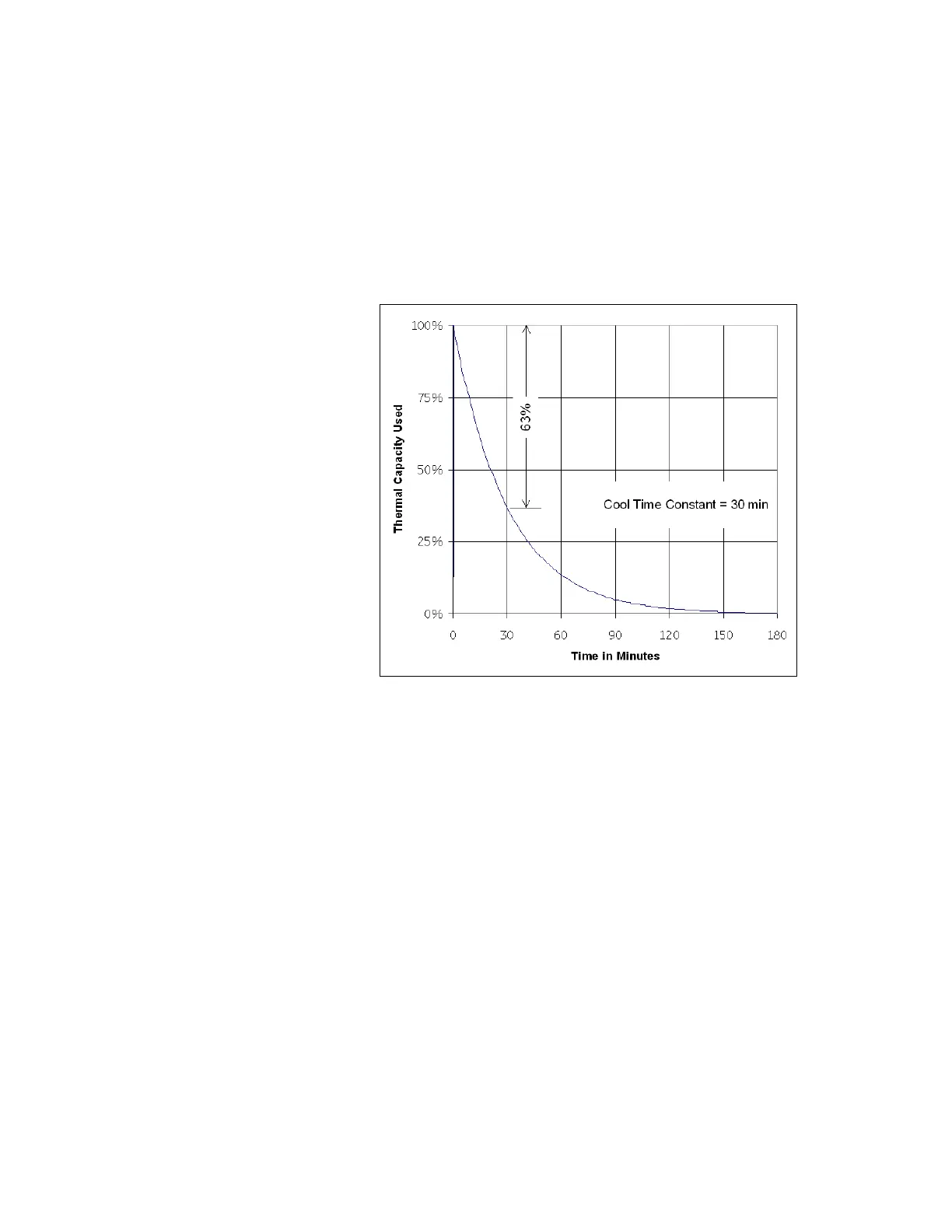

Figure 6-18: Thermal Protection Cooling Following a Trip at t = 0

THERMAL PROTECTION RESET

Thermal Protection operation is a serious event, and it consequently results in a lockout

that cannot be reset until the motor has cooled, unless an Emergency Restart or a Lockout

Reset is used. An Emergency Restart will reset the motor Thermal Capacity Used from its

current value to 0% so that a hot motor may be restarted. Note that a Lockout Reset does

not reset the Thermal Capacity Used register; if the motor is re-started it may re-trip

quickly. Should process interruption concerns overweigh the probable damage to the

motor that early starting would create, an Emergency Restart can be issued.

A setpoint AUTO RESET TCU≤15% is available to control whether once the motor has

cooled until the Thermal Capacity Used reaches 15% (approximately twice the Cool Time

Constant Stopped setting), the lockout is replaced with a trip that can be manually reset, or

alternatively the condition is fully reset, allowing immediate re-start.

THERMAL CAPACITY ALARM

A Thermal Capacity Alarm will occur when the Thermal Capacity rises above the

programmed THERMAL ALARM PKP level.

Loading...

Loading...