Weld334m - User’s manual

17

3.1.3

Power consumption

Power used is dependent on the type of application carried out on the machine.

Table below lists the minimum power to apply to the control device in its full configuration,

depending on the type of power supply being used.

Consumption

Power feeder Power supply type 24V Internal 24V External

F350/370 Vac Transformer (recommended): 110VA 62VA

F350/370 Vdc Power feeder (recommended): 80W 45W

3.2

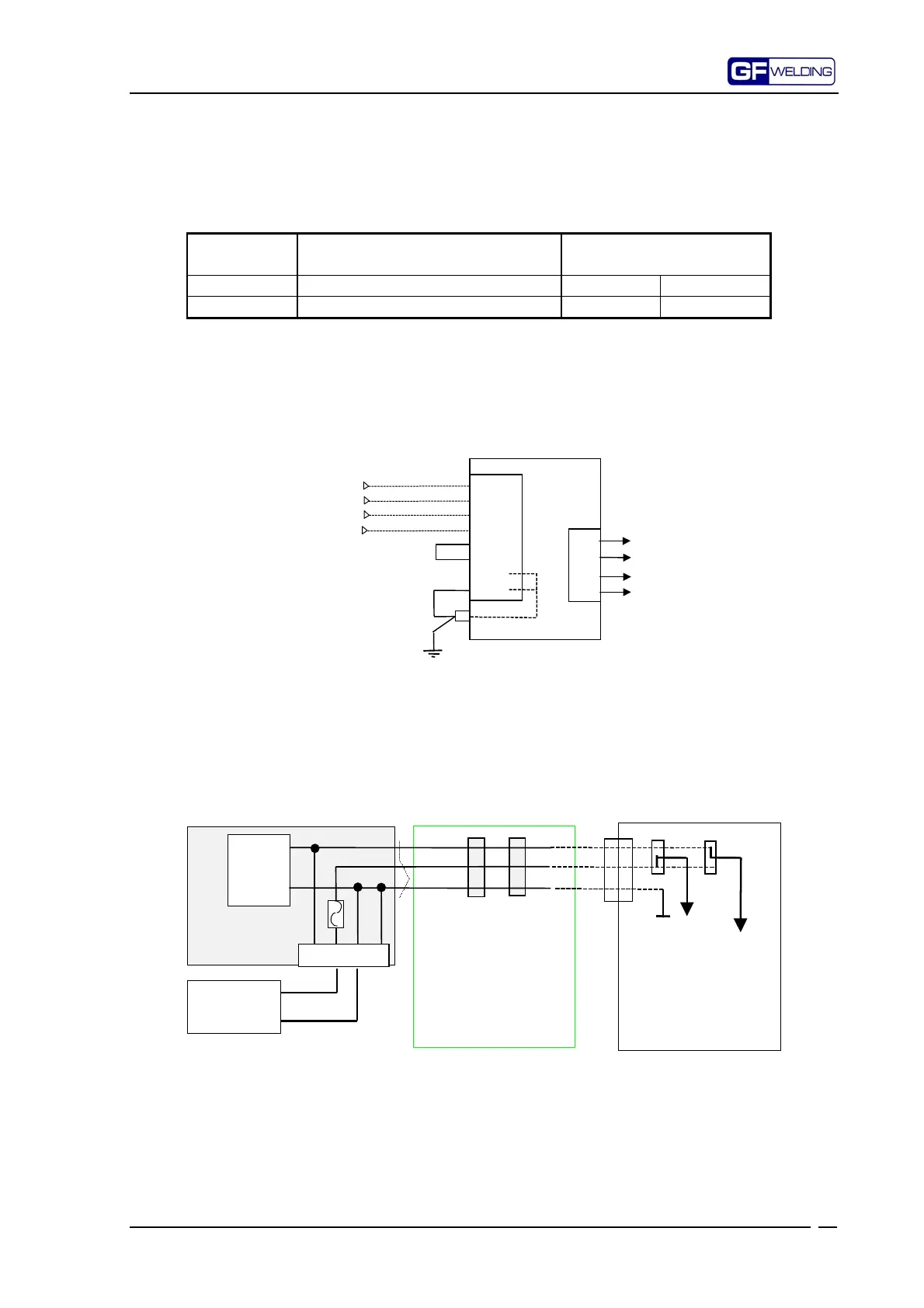

Use of 24V - I/O

To make use of 24V supply of I/O, certain rules are to be observed. These rules depend on

the type of application used on the machine.

The Weld334m is supplied by GF WELDING

in a standard configuration; 24V = make

jumpers between pin 5 and pin 6 (see figure below).

Faston

Power supply

External sync

1

2

3

4

5

6

7 0V

8 0V

PS

PWR

SYNC.

1

2

3

4

P20

Weld334

*

+24

0V

I/O

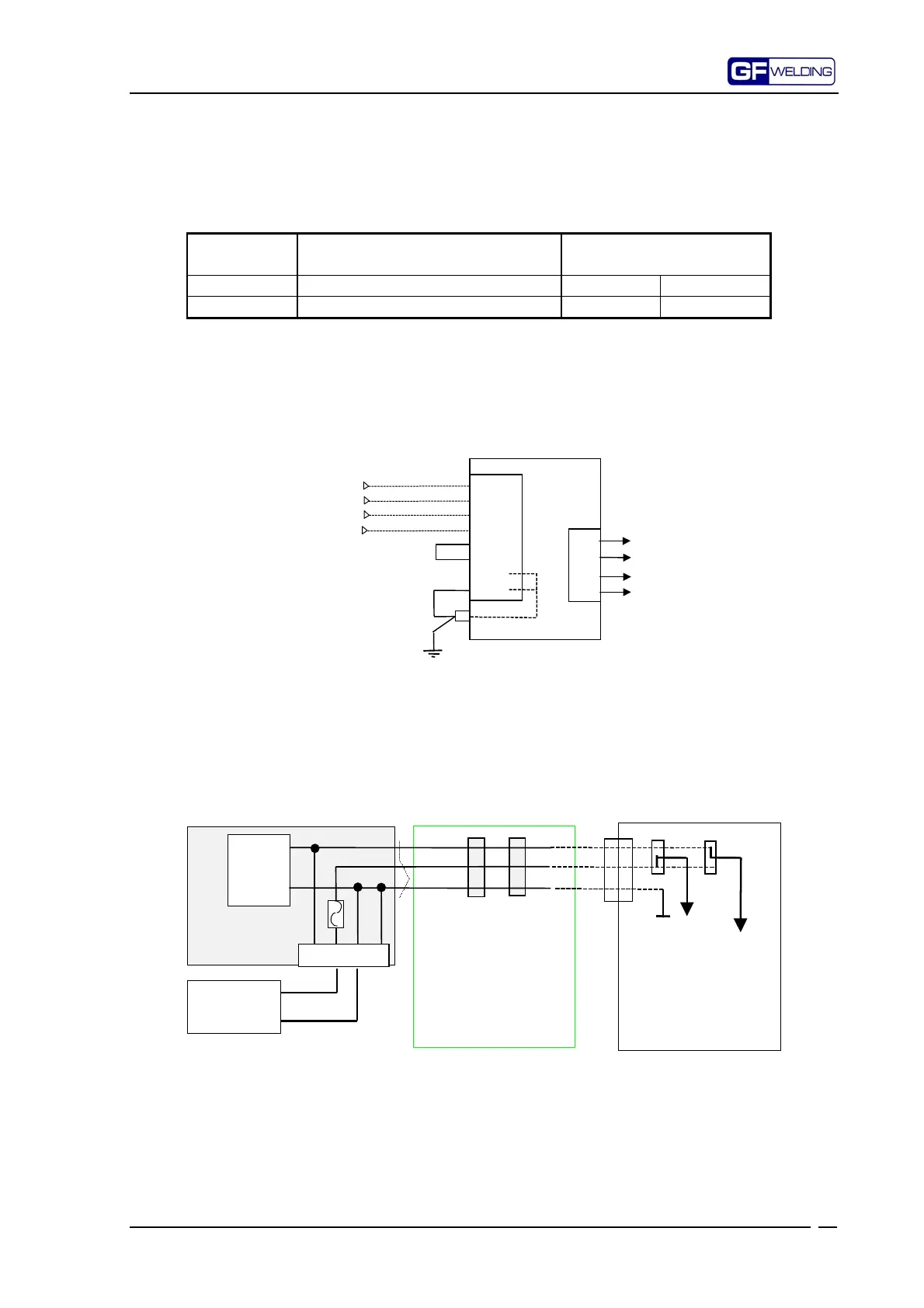

3.2.1

Selecting 24V – internal or external

24V supply for I/O input is distributed in such a way to have two internal separate lines.

These lines are alternate between one another:

•

One line for external 24V (24VE), whose input is located on pin 6 and pin 7 of PS

•

One for internal 24V (24VI) which, from the power feeder, is connected directly to

bus connectors JP2/3/4/5/6 (see figure 1).

Internal power

feeder

PS

BUS W334m

External power

feeder

24VE

5 6 7 8

24VI

0V

24VI

24VE

0V

JP2

JP3

J1

J2

24V I/O

24V

PULS.Com.

IMP.

1

2

3

1

2

3

IOB

module

P7

Figure 1

The modules using 24Vdc supply have 2 jumpers: J1 for 24V of I/O and J2 for 24V supply

used for the pulse control or the servovalve. These jumpers allow +24V supply to be set

toward the internal power feeder or toward an external+24V supply.

Each module is factory-calibrated (standard calibration) and calibration value is shown on

the layout page in the chapter concerning each module.

Figure 1 gives an example of setting for these 2 jumpers.

Loading...

Loading...