Weld334m - User’s manual

F376-OPC Field-Bus InterBus-S Card

50

UL

RD

FO1

BA

FO2

CC

FK

BE

SP

ST

MS

TR

11.3

InterBus-S interface power supply

There is a P25 connector on the front panel to supply the InterBus-S interface.

Connector type: 2 way, 5.08 pitch, disconnectable terminals.

Power supply input characteristics:

•

Acceptable Input voltage: 24Vdc -15%+10%

•

Max. Absorption: 125mA

The 0VIB return signal is not connected to the ground PE.

Pin Signal Description

1 +24VIB Power

20VIB Return

11.4

Description of status LEDs

There are 2 groups of LEDs on the front panel indicating the status of some I/O signals and

of the InterBus-S port.

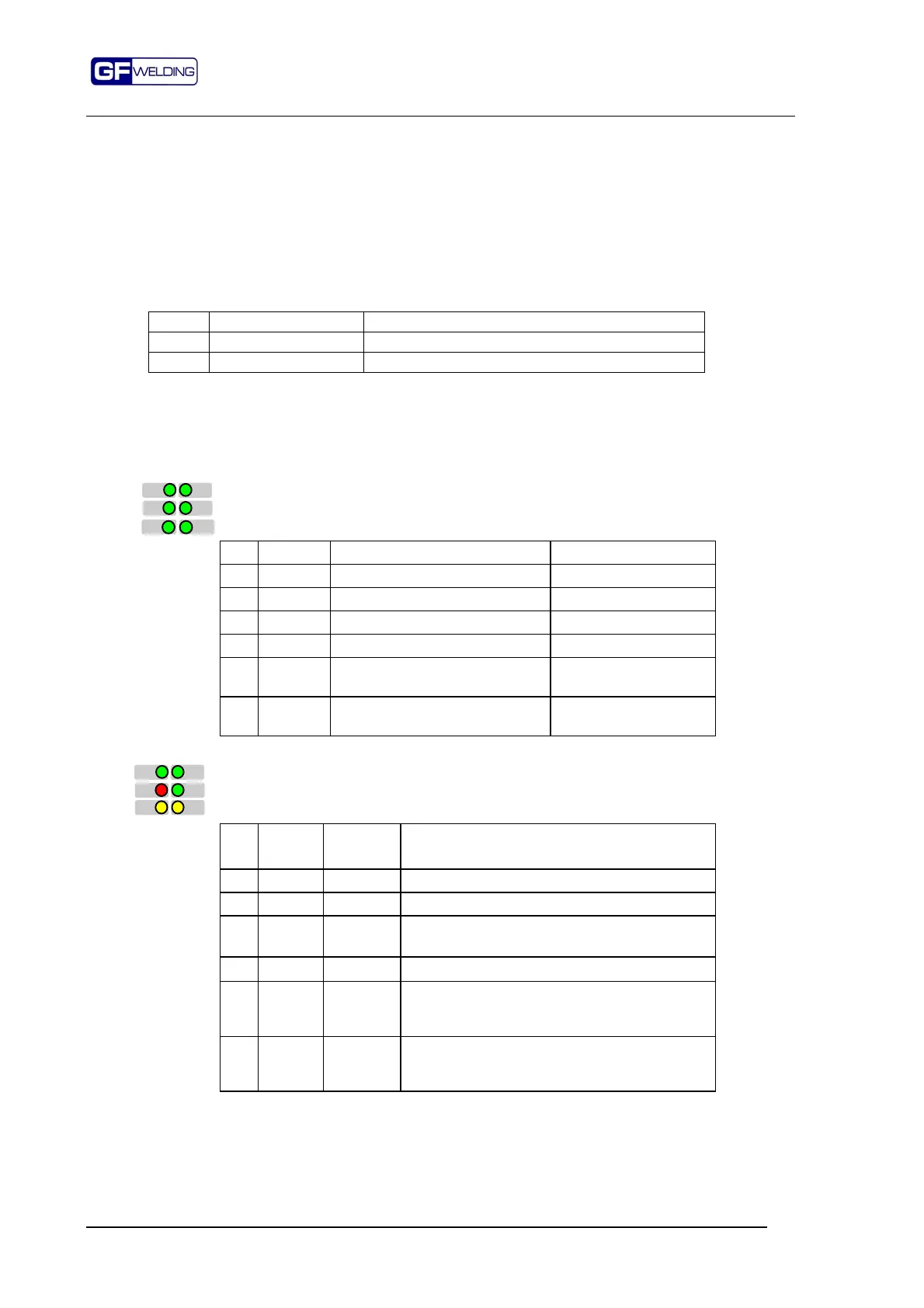

ST-FK-MS-BE leds

These LEDs indicate I/O functions dedicated to the welding process

Led Signal Condition Related bit

ST START Welding sequence start Control Word 1 Bit 0

FK FINESEQ Sequence end active Status Word 1 Bit 0

MS STATUS Weld YES enabled Control Word 1 Bit 7

BE READY Control device ready Status Word 1 Bit 4

TR Transmit

Receive

Communication through PCP

protocol active.

None

SP SPARE Not used. Available for future

uses.

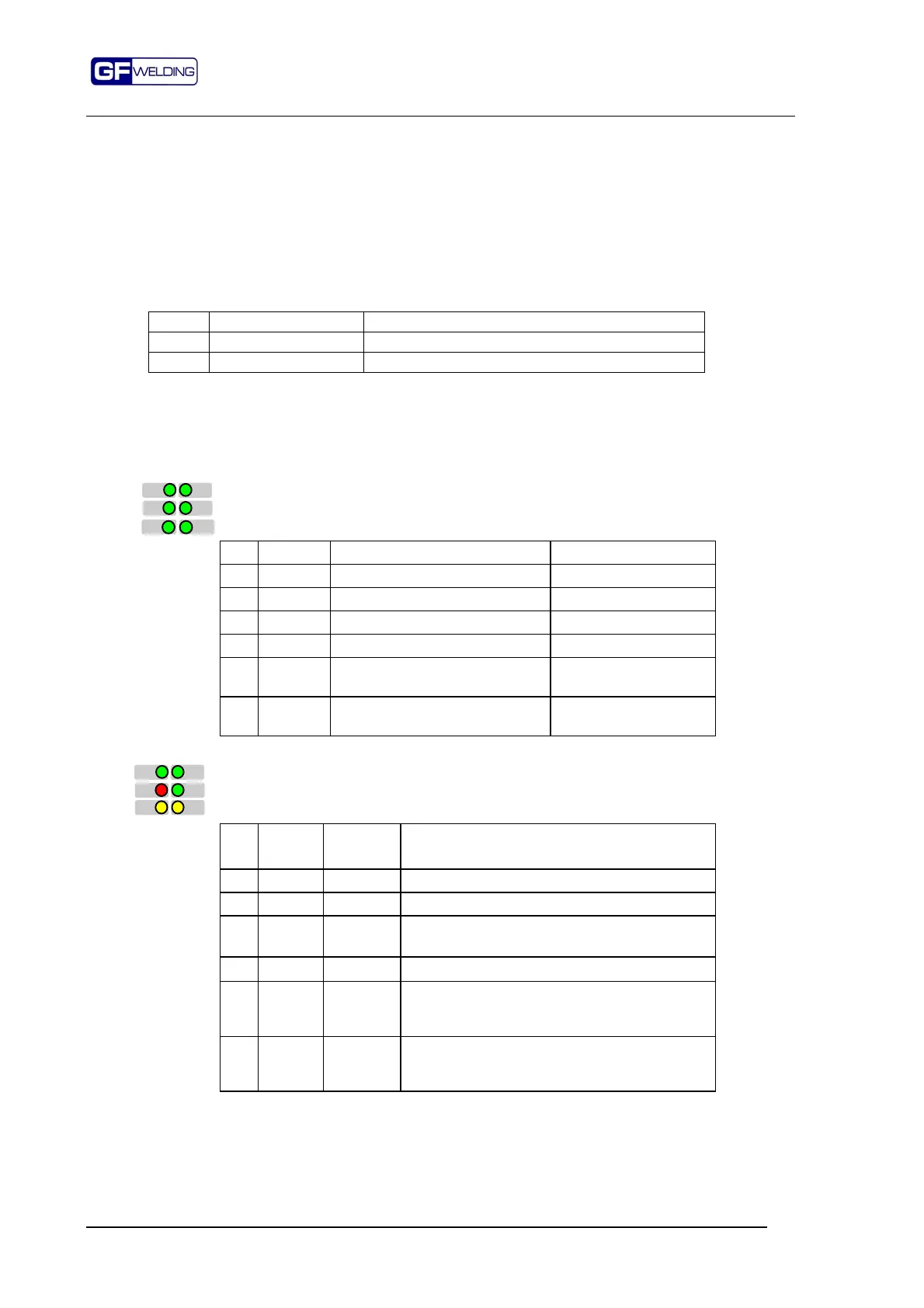

UL-RC-RD-BA LEDs

These LEDs

indicate InterBus-S port communication functions

Led Color Normal

status

Condition

UL Green On When OFF it indicates a reset condition

RC Green On when OFF it indicates InterBus-S reset active

RD Red Off

When ON it indicates BUS InterBus-S

disabled

BA Green On

When OFF it indicates InterBus-S inactive

FO1 Yellow Off When ON it indicates a fault on the REMOTE-

IN optical interface (e.g. reached limit level of

the optical fiber signal)

FO2 Yellow Off When ON it indicates a fault on the REMOTE-

OUT optical interface (e.g. reached limit level

of the optical fiber signal)

Loading...

Loading...