Weld334m - User’s manual

78

7 – Proportional Servovalve operating diagram

WELD GUN

VALVE

OFF

ON

START CYCLE

PROGRAM 1

(EV1=75%)

START CYCLE

PROGRAM 2

(EV1=25%)

EOCYCLE

PGM 1

EOCYCLE

PGM 2

Pressure %

100

75

50

25

0

xxxxxx

OFFEST = 20

EV1, of program 1

HOLD THE VALUE

VALUE

EV1, of program 2

HARDWARE RESET OR

CONTROL SWITCH-ON

t

Pressure % = Output air pressure, percentage of input pressure.

Examples: with: 5 bar input & EV1 @ 50 %; servovalve output = 2,5

" " " " " 75 % " " = 3,75

" " " " " 100 % " " = 5 bar (servovalve drop

not considered)

Servovalve parameters description:

OFFSET : 0 - 100 % ( active only after a reset; until a start cycle ) Stored in Setup function

EV1 : 0 - 100 % Nominal value during welding cycle Stored in each program

EV2 : 0 - 100 % Pressure variation value. Stored in each program

Change is done after n cycles; and in mode according the 5 available profiles

HOLD THE VALUE

t

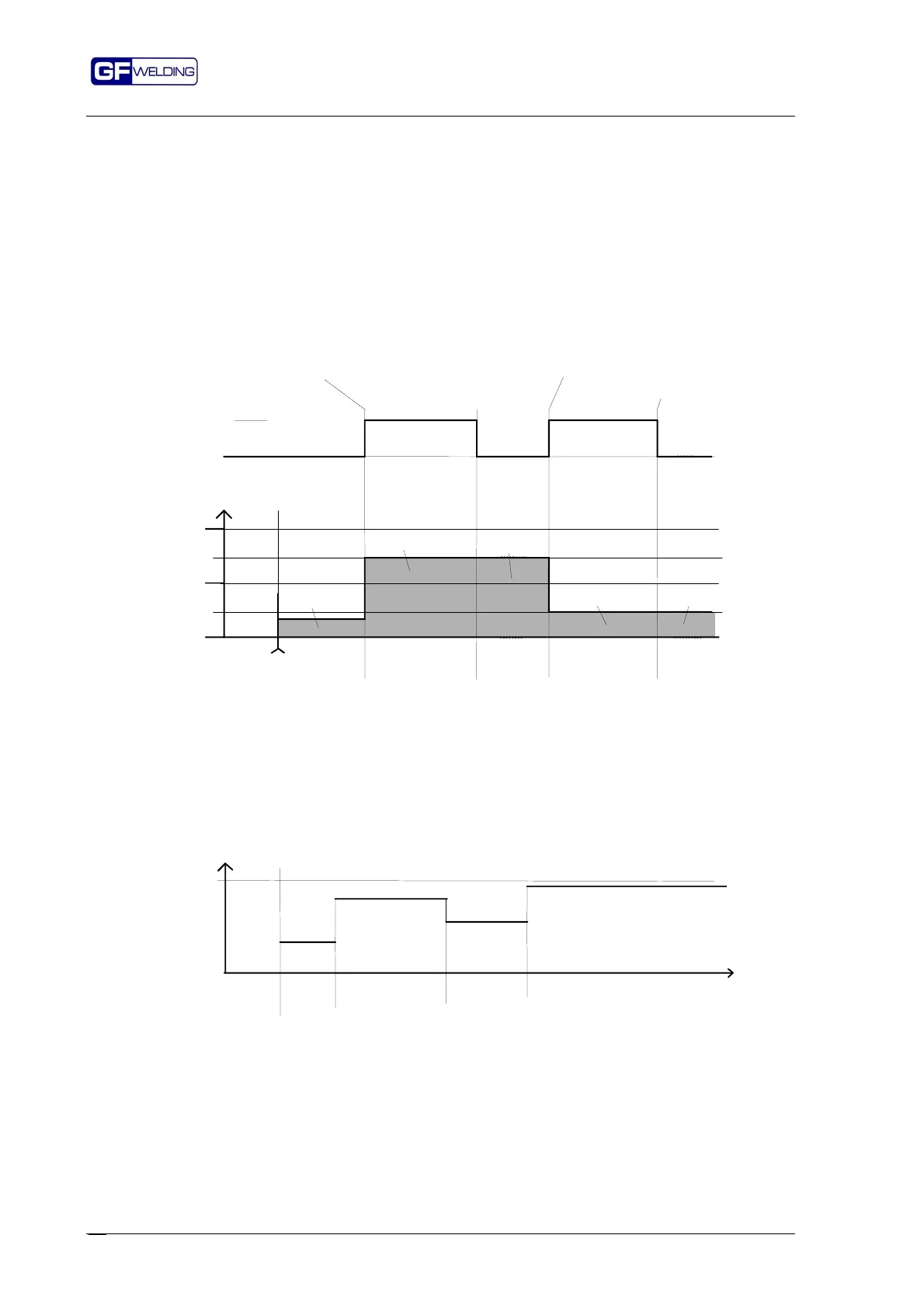

When the weld program code change (at the physical discrete inputs, or by serial line fielbus as Interbus-S or

Profibus DP or DeviceNet) immediatly the servovalve command output will be upgrated according the EV1 value

stored in the program choosed. Also without the Start signals. This function is always active.

Pressure

%

0

100

xxxx

offset

HARDWARE RESET OR

CONTROL SWITCH ON

WELD PROGRM

CHANGE CODE

(i.e. # 1

WELD PROGRM

CHANGE CODE

(i.e. # 2

WELD PROGRM

CHANGE CODE

(i.e. # 3

t

All changes without start cycle command

Loading...

Loading...