Weld334m - User’s manual

18

24V I/O can be managed in the following ways:

◊

Direct

: 24VI supply with pins 5 - 6 of PS being free (see paragraph

3.2.2 figure

a

)

J1 connector: jumpers of I/O and ADC cards to be made in position 1-2.

◊

Indirect

: 24VI supply with pins 5 and 6 of the PS: make jumpers or cut them out

from a contact (see paragraph

3.2.2 figure

b

).

24VI supply, which in this way can be cut out from the outside (enabled/disabled),

is re-closed on 24VE line.

◊

External

: with external 24V supply connected to pin 6 and pin 7 of the PS (see

paragraph

3.2.2 figures

c

and

d

)

.

Summary Table of 24V I/O jumpers of cards

24V Selection J1 J2*

Internal 1-2 1-2

Internal indirect 2-3 1-2

External 2-3 2-3

* Where present

3.2.2

24V connections for discrete I/O

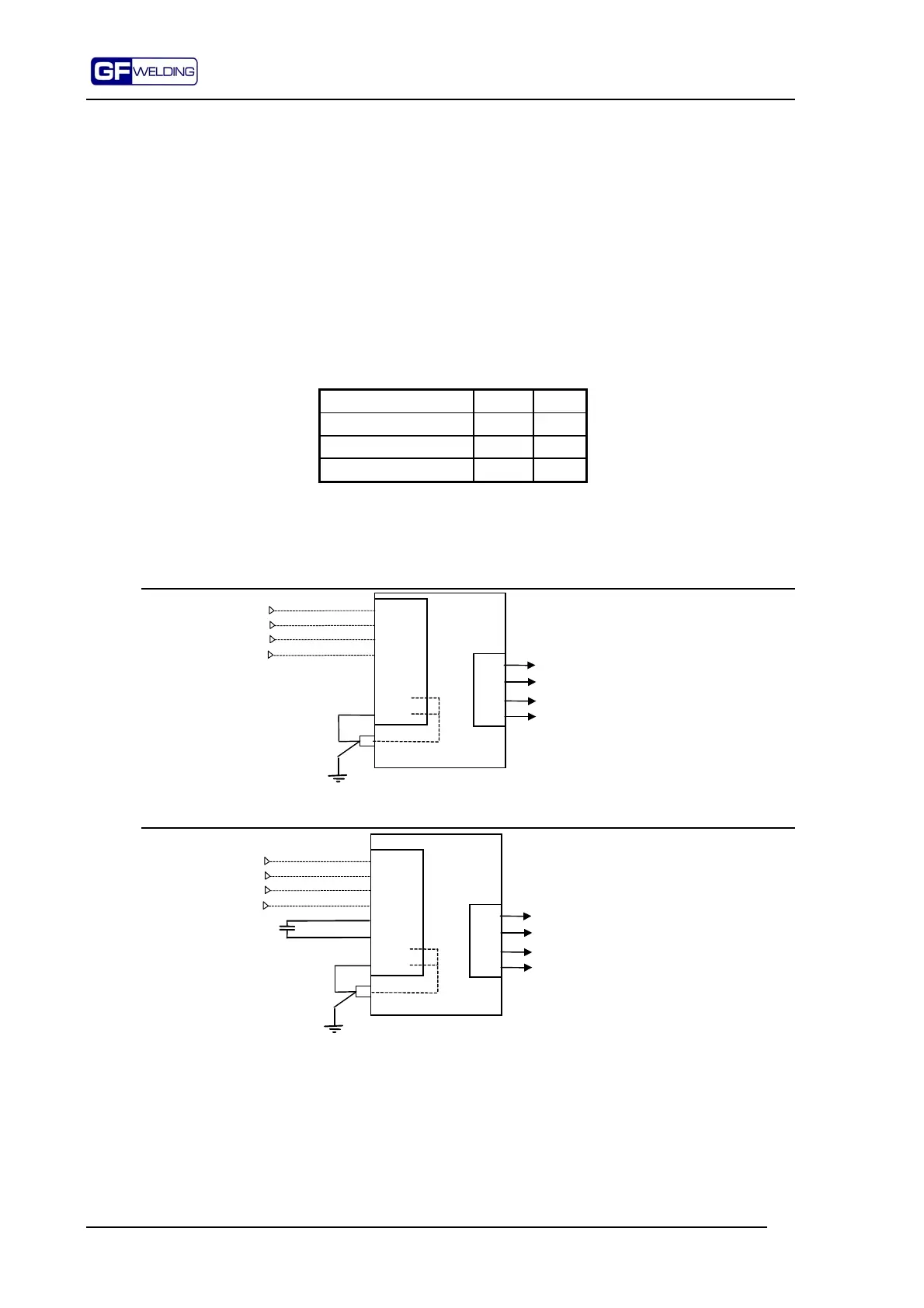

Figure a: Use of +24VI supply in direct way

Faston

Weld334m

1

2

3

4

5

6

7 0V

8 0V

PS

PWR

SYNC.

Power supply

External sync

1

2

3

4

P20

*

+24

0V

I/O

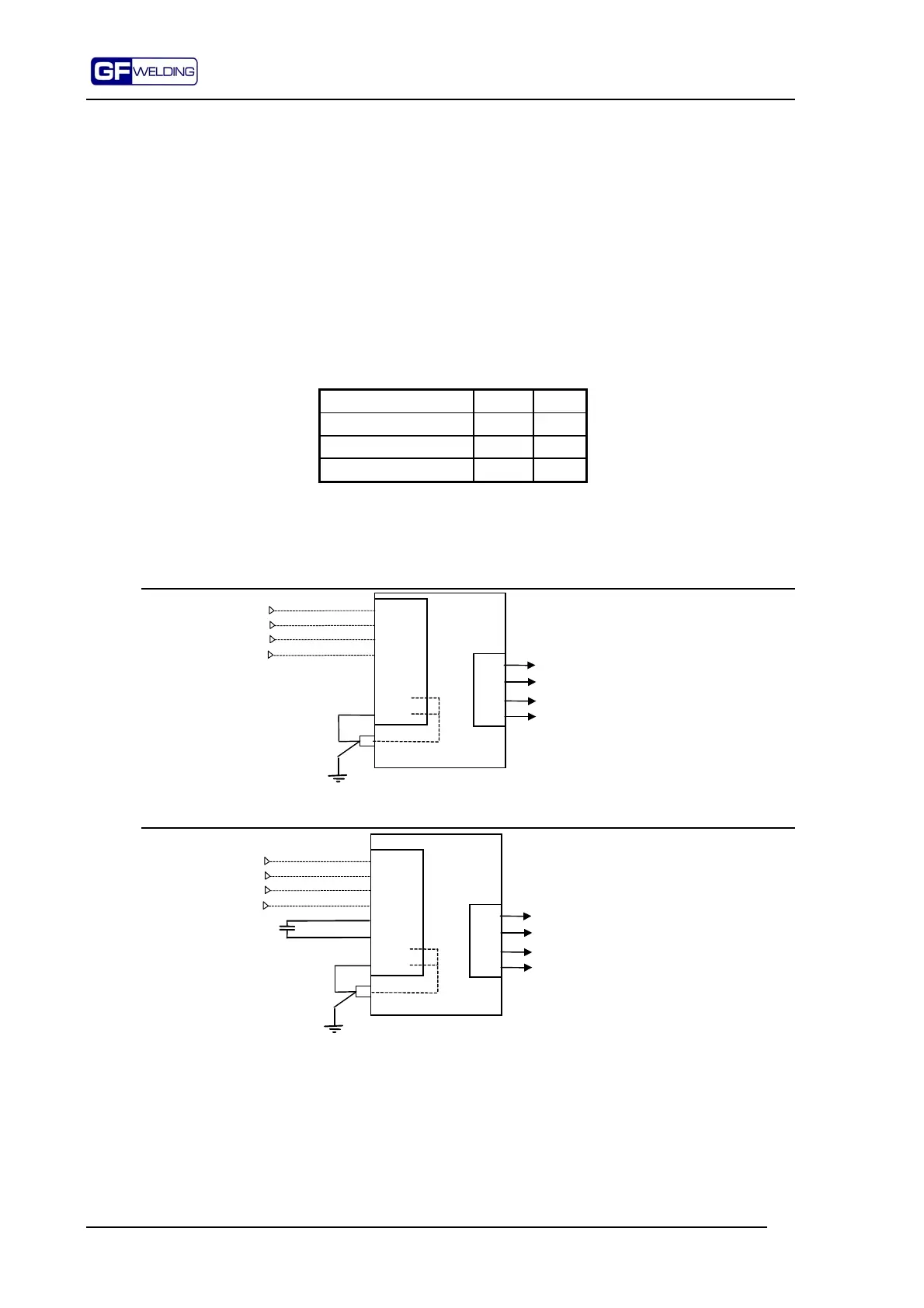

Figure b: Use of +24VI in indirect way

Faston

Power supply

External sync

1

2

3

4

5

6

7 0V

8 0V

PS

PWR

SYNC.

1

2

3

4

P20

Weld334m

*

+24

0V

I/O

24VI is cut off on the PS between pin 5 and pin 6. Thus, 24V supply of I/Os can be enabled and

disabled independently of the control device.

Loading...

Loading...