Weld334m - User’s manual

F360-IOB I/O Basic card

39

P21 – Functional description of signals

Pin Signal Function

9 FINE SEQ.

Output active at 24V.

At the end of frequency cycles (electrode opening), the control device

activates this output and terminates the sequence.

If Repeat Function is enabled, the End of Sequence is not performed and

the control device goes on starting from pressure cycles. (See diagrams

relevant to cycle time on the programming manual)

10

11

RICHSALD

+

RICHSALD-

Output.

NO relay contact.

At the end of the pressure cycles, the control device, ready to execute

the welding pulse, activates the request for welding and waits for the

consent (CONSALD - CONS. TO WELDING).

It needs a common wire (contact 11) connected to 24V.

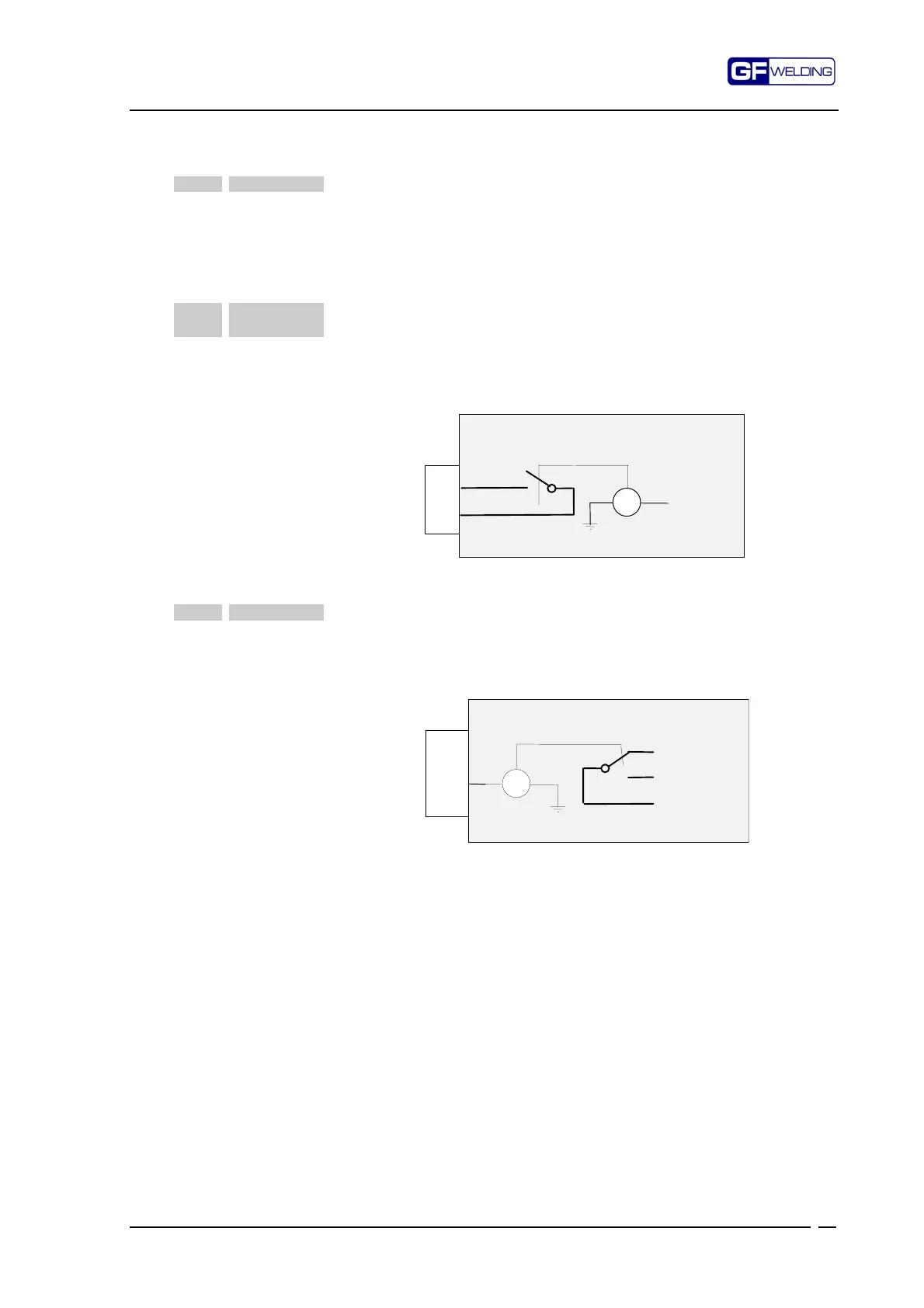

P21

10

11

RICHSALD

Commun

RICHSALD

R

.for Weld

K

F360-IOB

For the connection, refer to application diagrams

12 CONSALD

Consent to welding.

Input active at 24V.

The consent to welding is the enable signal for welding; it is an indication

that the welding machine is ready. It is tested after the Request for

Welding Signal has been activated.

When not in use, this input is to be connected to 24V.

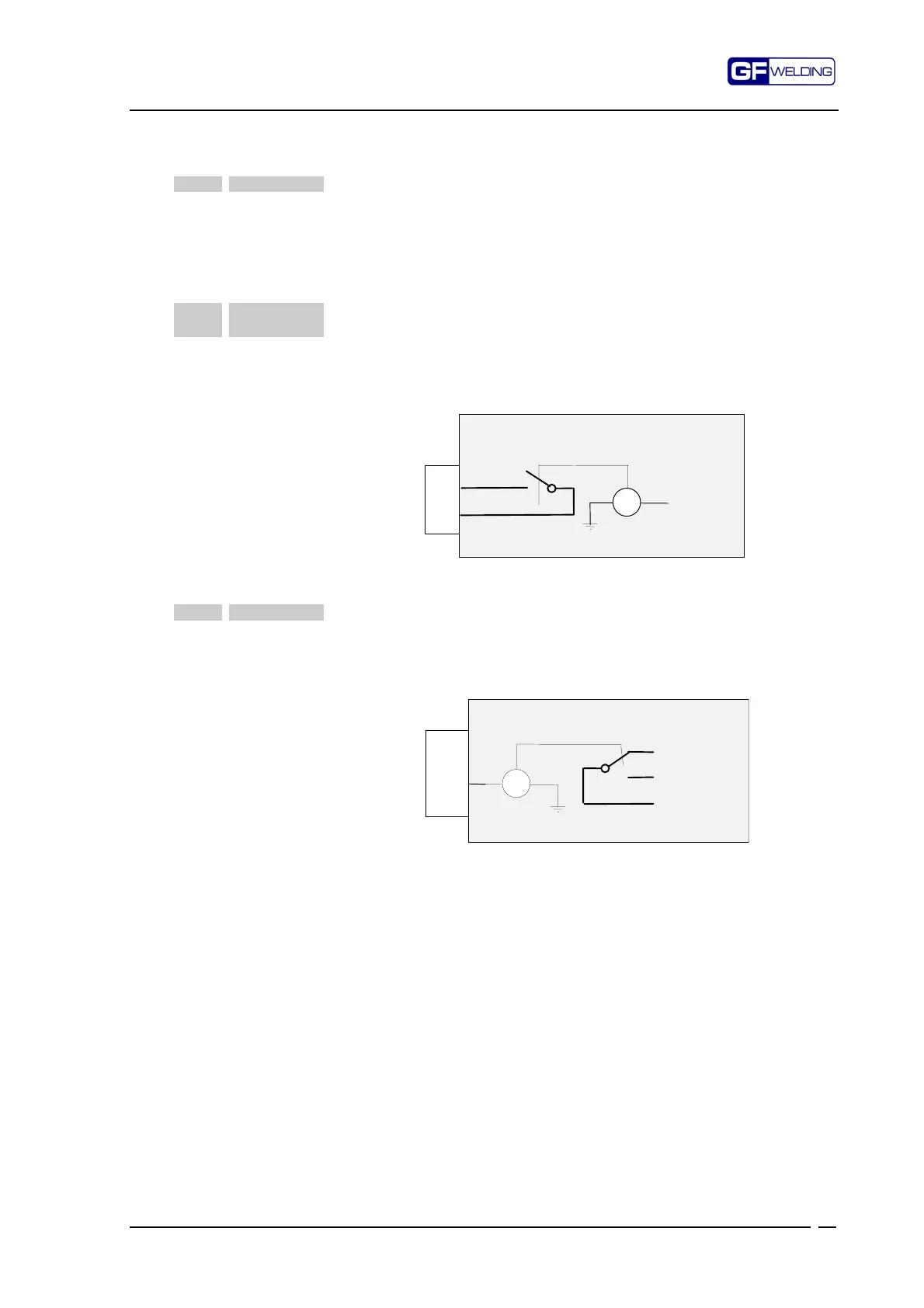

F360-IOB

P21

12

CONSALD

24V

CONSALD

(

Cons. to Weld)

K

For the connection, refer to application diagrams

Loading...

Loading...