Spray

28 3A0420V

Heat Fluid

To heat fluid evenly throughout the system:

1. Circulate the fluid at approximately 1/2 gpm

(10-20 cycles/min.) to raise the temperature of the

hoppers to 80-90° F (27-32° C).

2. Decrease the circulation rate to approximately

0.25 gpm (5 cycles/min.) to increase the heater out-

let temperature to match the spray temperature.

NOTE: Circulating the fluid too quickly without

decreasing the circulation rate will increase only the

hopper temperature. Similarly, circulating fluid too

slowly will increase only the heater outlet tempera-

ture.

Spray

NOTE: After the first day of spraying follow Pres-

sure Relief Procedure, page 24, and tighten the

throat packing nuts on both pumps.

1. If heaters are used, turn them on. To adjust the

heater temperature, refer to the Viscon HP manual

for instructions, and the Heat Fluid section, page

28. Circulate as necessary.

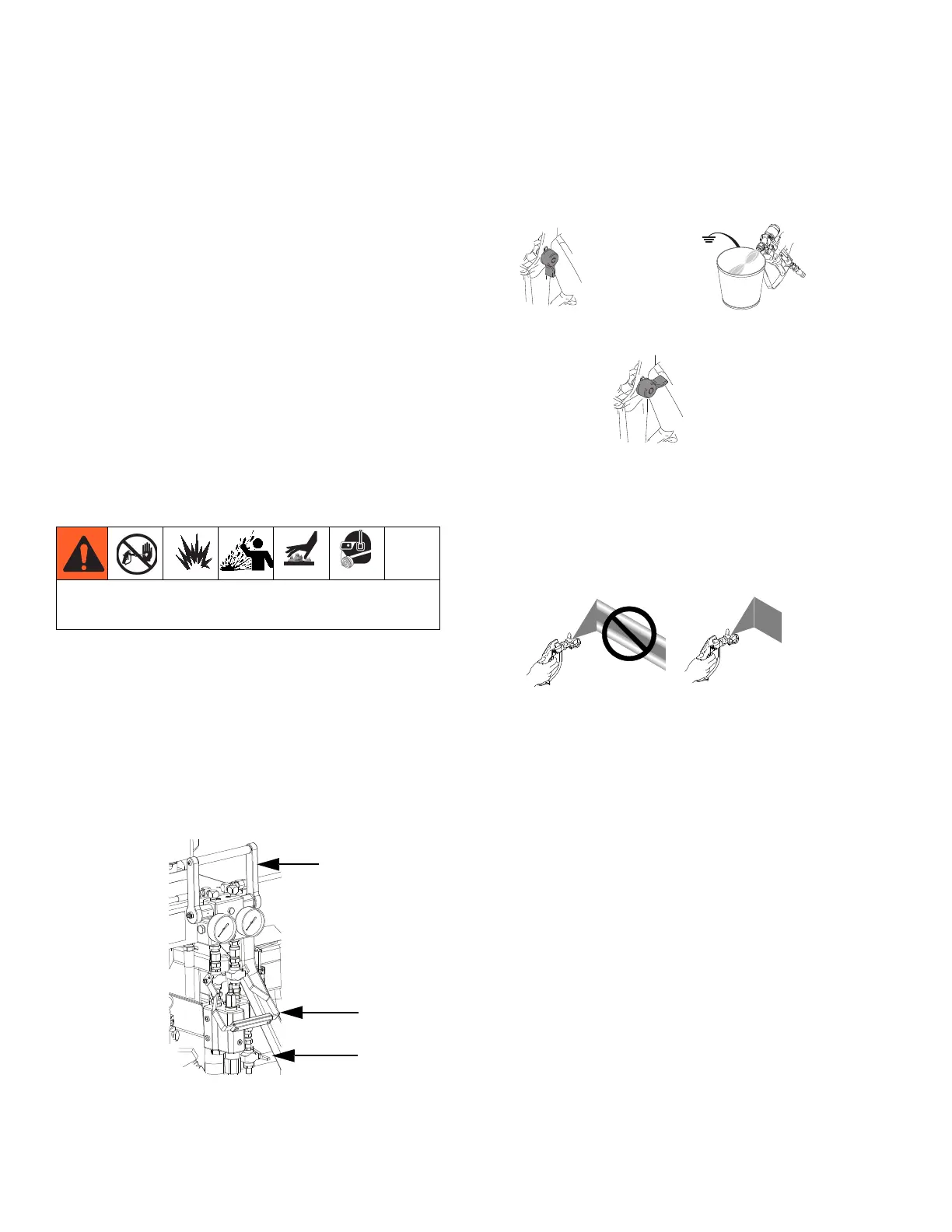

2. Close the circulation handle (AC) and the solvent

flush valve (AD). Open the dual shutoff handle (AE).

3. Adjust the main air regulator (CB) to 30 psi

(0.21 MPa, 2.1 bar).

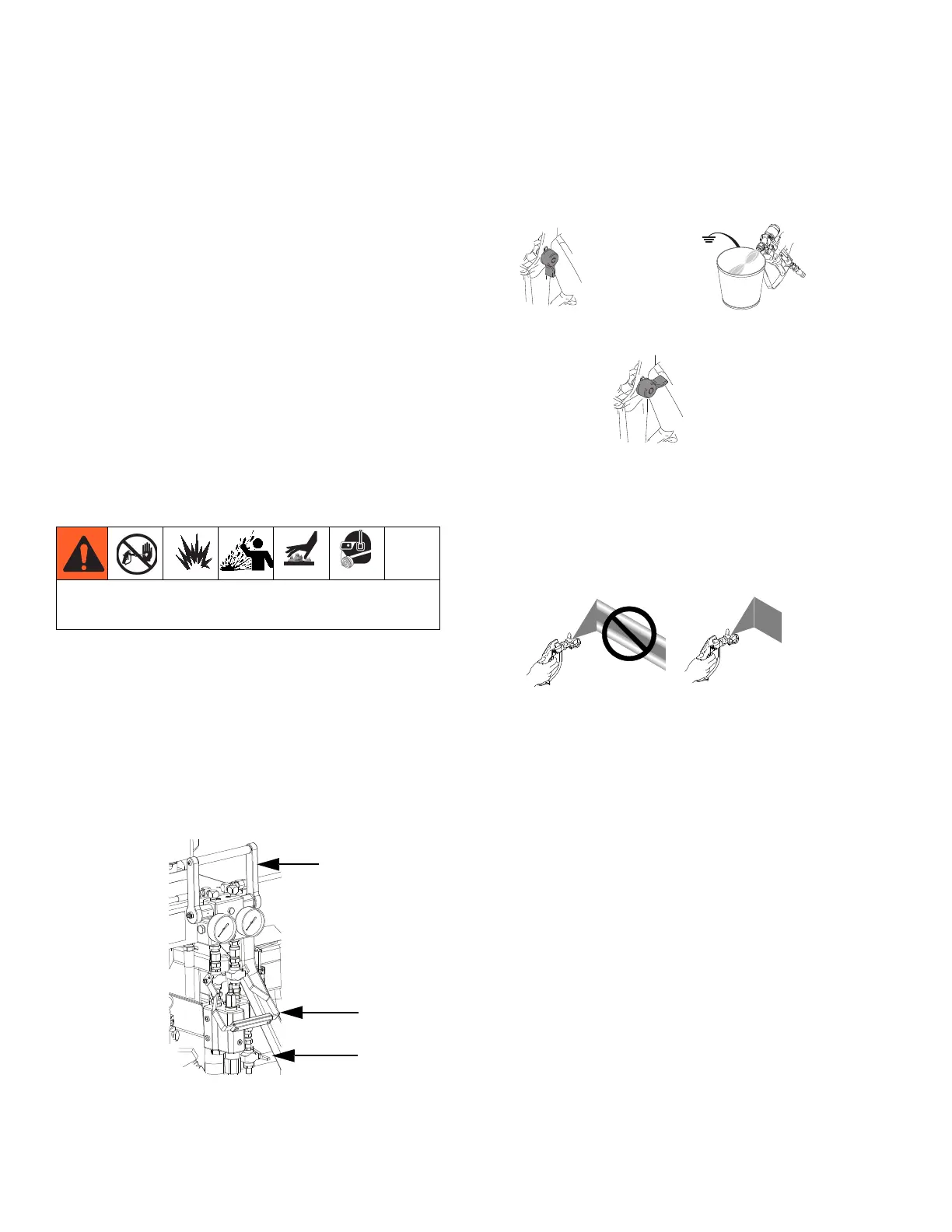

4. Remove tip. Disengage the trigger lock and trigger

the gun into a grounded metal pail. Use a metal pail

lid with a hole to dispense through to avoid splash-

ing. Dispense out of the mix hose until a well mixed

coating flows from the gun.

5. Engage the trigger lock. Install the tip on the gun.

6. Adjust the main pump air regulator (CB) to the nec-

essary spraying pressure and apply a coating to a

test panel.

NOTE: Run system verification tests everyday. See

page 34.

7. Excess pressure increases overspray and pump

wear.

8. Check and record gauge readings frequently during

operation. A change in gauge readings indicates a

change in system performance.

NOTE:

• A pressure drop occurs during pump stroke

changeover. It should be quick and synchro-

nous.

• Flush the mix manifold as necessary during the

day’s operation.

9. Follow Flush Mixed Material, page 30 when you

are finished spraying or before potlife expires.

NOTE: Mixed material potlife or working time

decreases with increased temperature. Pot life in

the hose is much shorter than the dry time of the

coating.

Wear gloves when using flush solvents and/or if fluid

temperature exceeds 110°F (43°C).

Loading...

Loading...