-12-

G1026 Heavy-Duty Shaper

Most of your Model G1026 Shaper has been

assembled at the factory, but some parts must

be assembled or installed after delivery. We

have organized the assembly process into steps.

Please follow along in the order presented here.

TOOLS REQUIRED: You will need a 12" to 18"

long straightedge, 12, 14, and 17mm open end

wrenches, 4 and 8mm hex wrenches, and a

Phillips and flat head screwdriver.

Beginning Assembly

Wear safety glasses dur-

ing the entire assembly

process. Failure to com

-

ply may result in serious

personal injury.

Some metal parts

may have sharp edges

on them after they are

formed. Please examine

the edges of all metal

parts before handling

them. Failure to do so

could result in injury.

Disconnect power from

the machine when per

-

forming any maintenance,

assembly or adjustments.

Failure to do this may

result in serious personal

injury.

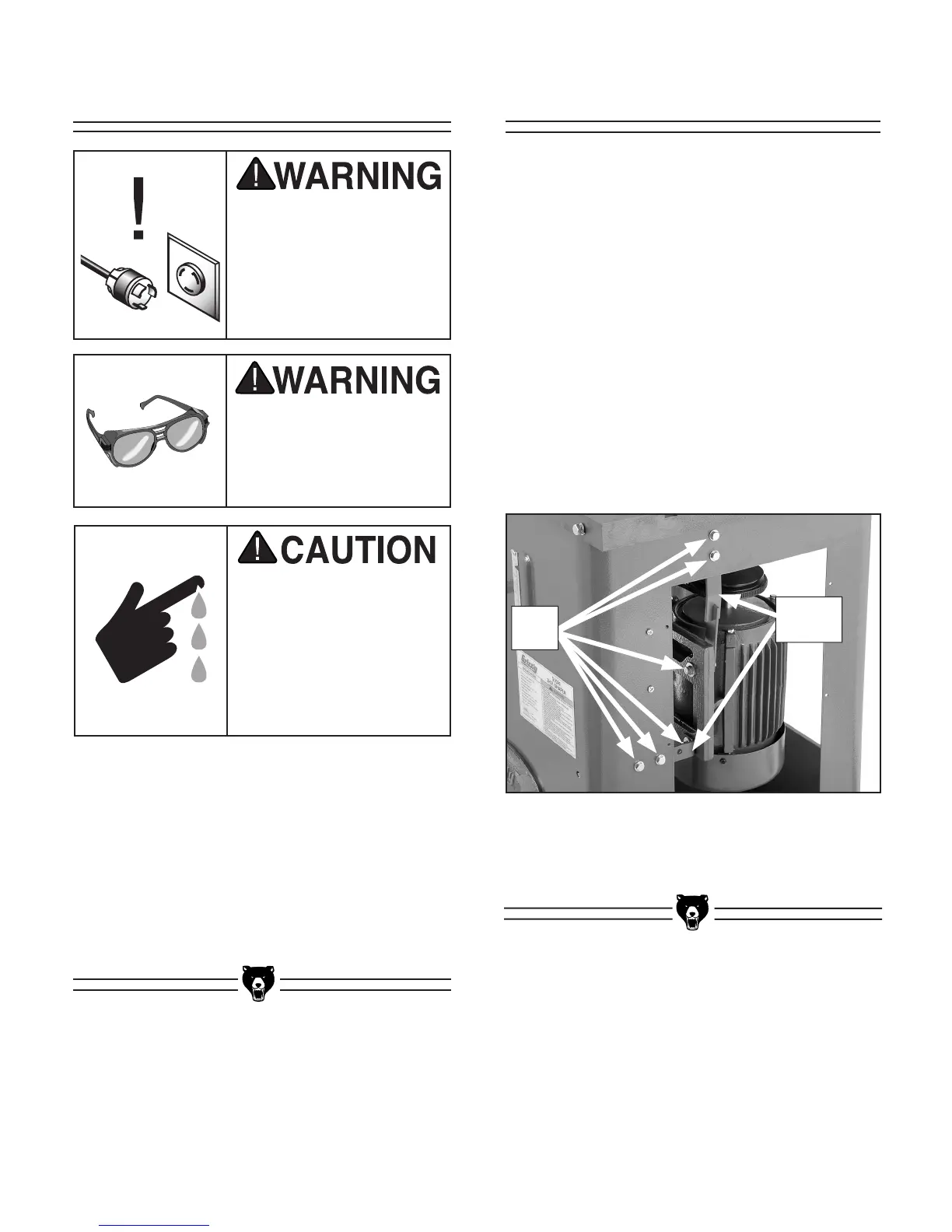

Motor Brace

The Model G1026 is equipped with motor braces

to prevent damage to the motor during shipping.

These braces are intended to be removed before

operation.

To remove the motor braces:

1. KEEP SHAPER DISCONNECTED FROM

POWER!

2. Remove the motor cover from the shaper

cabinet by removing six screws that hold it in

place.

3. Using a 12mm wrench, remove the six hex

bolts, hex nuts and flat washers and the two

motor braces shown in

Figure 3.

Figure 3. Motor braces and hex bolts.

4. Reinstall all the fasteners removed in Step

3.

Hex

Bolts

Motor

Braces

Loading...

Loading...