G1026 Heavy-Duty Shaper

-7-

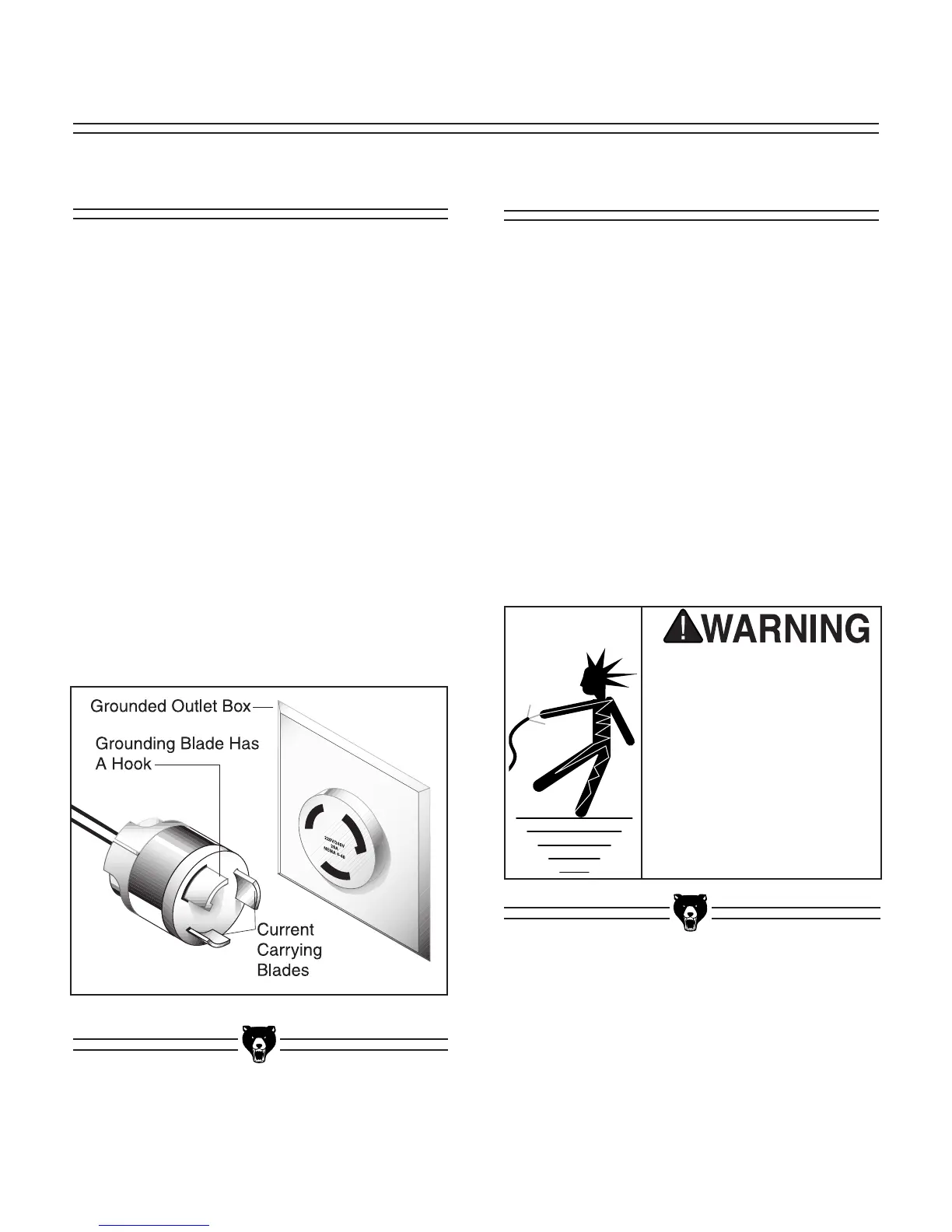

Figure 1. Recommended plug configuration.

220V Operation

The G1026 Shaper is furnished with a 3450

R.P.M. 3 H.P., 220V motor, push-button ON-OFF

magnetic starter switch, forward-reverse switch

and a cord set. Under normal use, the motor draws

approximately 18 amps at 220V. We recommend

a 20 amp circuit breaker or a 20 amp slow-blow

fuse. If frequent circuit failures occur when using

the shaper, contact our service department.

The shaper motor must be connected to its own

dedicated 20 amp circuit. It should not share a

circuit with any other machine. A standard 2-pole

breaker should be satisfactory for use with the

shaper.

We recommend using a NEMA-style L6-20 plug

and outlet shown

Figure 1. You may also “hard-

wire” the shaper directly to your panel, provided

you place a disconnect near the machine. Check

the electrical codes in your area for specifics on

wiring requirements.

Grounding

SECTION 3: CIRCUIT REQUIREMENTS

In the event of a malfunction or breakdown,

grounding provides electric current a path of least

resistance to reduce the risk of electric shock.

This tool is equipped with an electric cord having

an equipment-grounding conductor which must

be properly connected to a grounding plug. The

plug must be plugged into a matching outlet that

is properly installed and grounded in accordance

with all local codes and ordinances.

Improper connections of the electrical-grounding

conductor can result in risk of electric shock. The

conductor with green or green and yellow striped

insulation is the electrical-grounding conductor.

If repair or replacement of the electric cord or

plug is necessary, do not connect the equipment

grounding conductor to a live terminal.

This equipment must be

grounded. Verify that any

existing electrical out

-

let and circuit you intend

to plug into is actually

grounded. Under no cir

-

cumstances should the

grounding pin from any

three-pronged plug be

removed. Serious injury

may occur.

Loading...

Loading...