G1026 Heavy-Duty Shaper

-27-

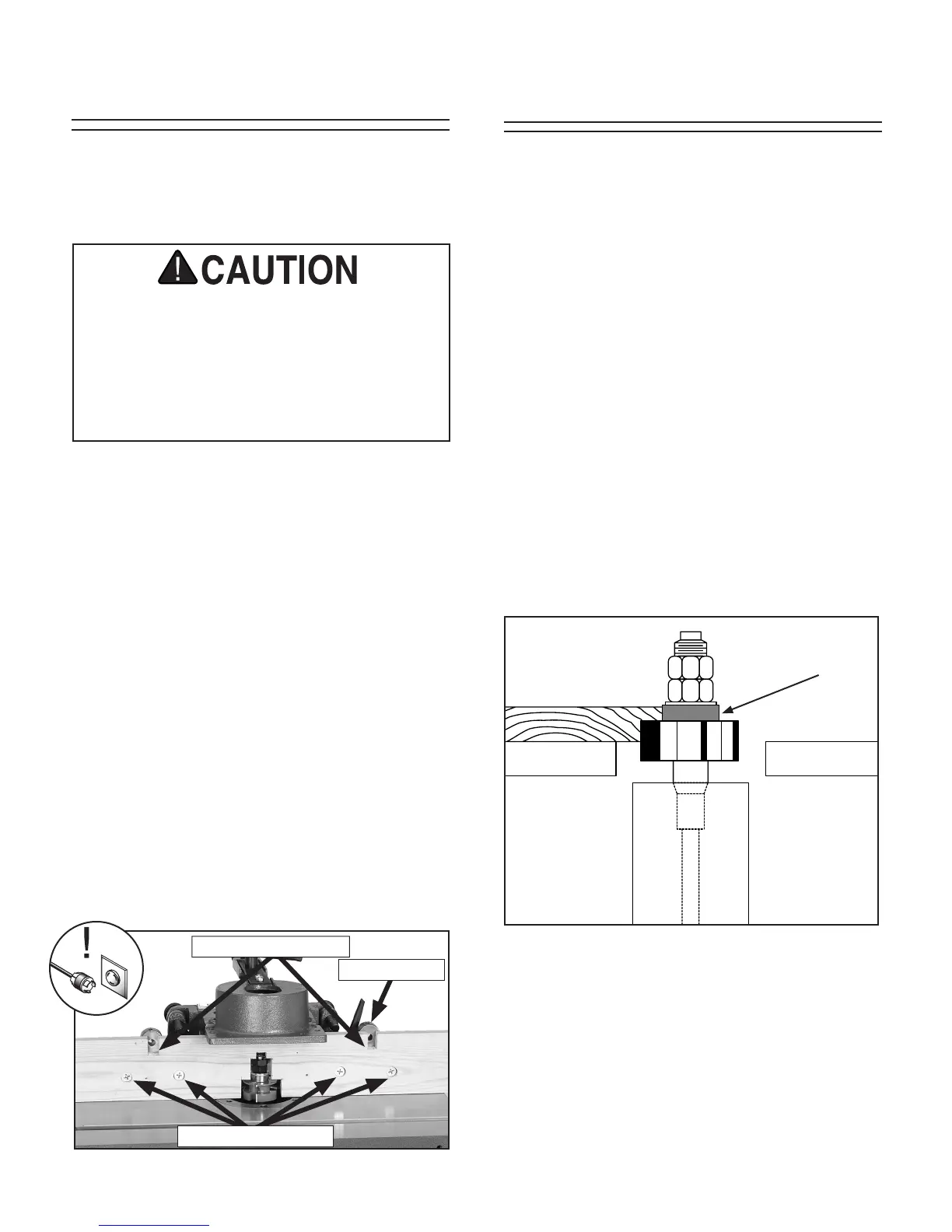

Figure 38. Rub collar installed above cutter.

2. Rub collar below the cutter: When the rub

collar is used below the cutter (See Figure

39), the progress of the cut can be observed.

However, any unintentional movement may

lift the workpiece into the cutter, damaging

your work and creating a dangerous situa

-

tion. We DO NOT recommend this setup.

Rub Collars

Rub collars are used when shaping curved or

irregular workpieces, such as arched doors or

round table tops, and to limit the depth of your

cut.

There are two types of rub collars—solid and

ball-bearing. We recommend using ball bearing

collars and we carry an extensive line that is

designed for use with Grizzly shapers. See our

current catalog or website for listings.

Rub collars may be used in any of the follow

-

ing positions:

1. Rub collar above the cutter (preferred):

When the rub collar is used above the cut

-

ter, the cut cannot be seen. See Figure

38.

This offers some advantage: the stock is

not affected by slight variations in thickness

and accidental lifting will not damage the

workpiece. If lifting occurs, simply correct the

mistake by repeating the operation.

Rub Collar

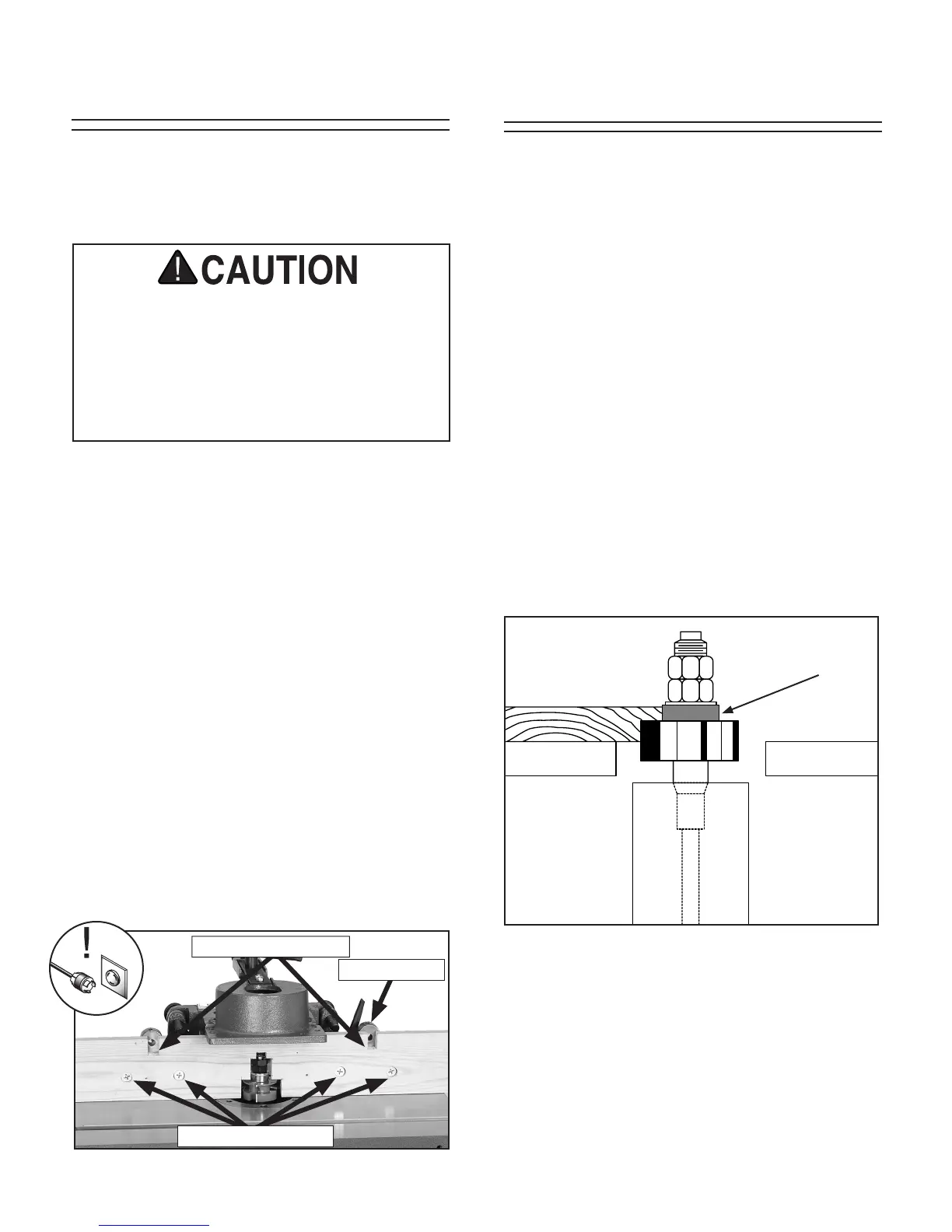

Shaping Small Stock

Shaping small stock is inherently dangerous on

a shaper. Consider making a zero-clearance

fence

(Figure 37) to provide more support than a

standard fence and reduce tearout on narrow or

fragile stock.

Figure 37. Example of a zero clearance fence.

Always use hold downs or featherboards

when shaping small or narrow stock. These

devices will keep your hands away from the

spinning cutterhead and support the stock

sufficiently to allow a safe and effective cut.

Failure to follow this warning may lead to

severe personal injury.

Fence Mount

Holes for Fasteners

Hold Down Notches

To make a zero-clearance fence:

1. DISCONNECT SHAPER FROM POWER

SOURCE!

2. Remove the wood facing and fasteners on

the split fence.

3. Place a 1 x 4 over the fence mounts and mark

and drill four holes for securing the board to

the mounts.

4. Transpose an outline of the spindle, cutter,

and its components onto the board, leaving

room for the moving parts so they will not hit

the board.

5. Using a bandsaw, cut out the outline.

6. Cut out notches in the top of the board for

attaching hold downs, as shown in

Figure

37 and secure it to the fence mounts with the

fasteners removed in Step 1

.

Loading...

Loading...