G1026 Heavy-Duty Shaper

-23-

Cutter Installation

Your shaper operates at speeds of 7,000 and

10,000 RPM. 3

1

⁄

2

" or larger cutters must be oper-

ated at the slower speed. Always use the largest

spindle size possible, and never use a cutter bore

more than one size larger than the spindle size.

To install a cutter:

1. DISCONNECT SHAPER FROM POWER

SOURCE!

2. Loosen the knurled lock knob and temporarily

move the main safety guard out of the way.

3. If needed, place an appropriate spacer or col-

lar at the base of the spindle for support.

4. Place the cutter on the spindle. Make sure

the rotation is correct for your application.

5. Use spacers or collars to suit your particular

application.

6. Place a spindle washer above the cutter and

screw on the nut and locknut as shown in

Figure 27.

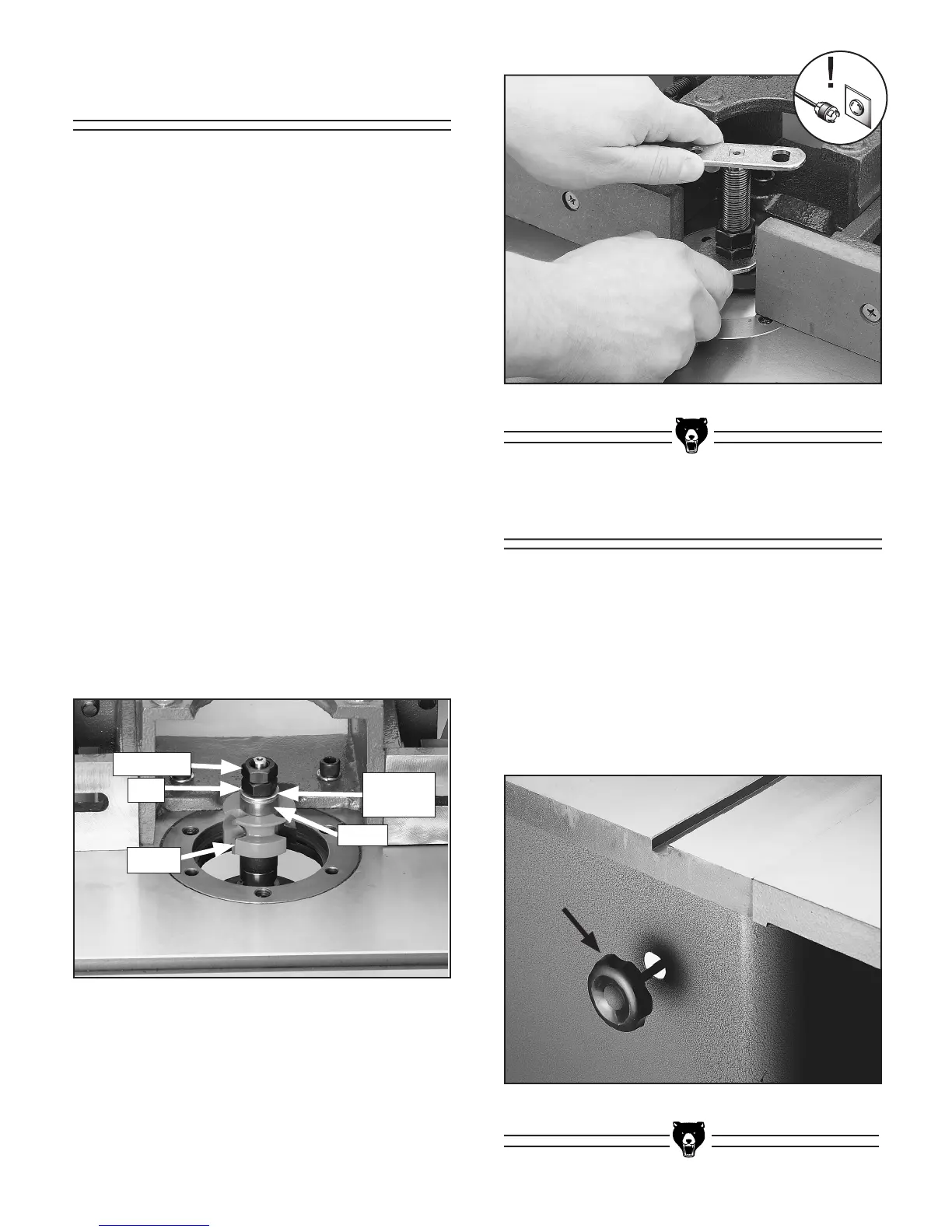

7. Tighten the nuts while holding the spindle

stationary. Place a spindle wrench on the

notches at the top of the spindle for leverage

as shown in

Figure 28.

8. Replace the safety guard.

Figure 27. Cutter and fasteners.

Lock Nut

Nut

Spindle

Washer

Cutter

Collar

Spindle Height

To adjust the cutter height:

1. Loosen the spindle lock. See Figure 29.

2. Move the spindle up or down with the eleva-

tion handwheel until the desired position is

obtained.

3. Lock the spindle into position.

Figure 29. Spindle lock knob.

Figure 28. Tightening spindle nuts.

Loading...

Loading...