G1026 Heavy-Duty Shaper

-29-

7. Connect the shaper to the power source.

8. Turn the shaper ON.

9. Make a sample cut on a piece of scrap

wood.

10. If everything is correct, feed your workpiece

along the cutter, using firm pressure to

keep your work against the rub collar. Feed

against the cutter rotation only.

11. Turn the shaper OFF.

Incorrectly feeding stock (feeding with the

rotation of the cutter) creates a potentially

uncontrollable feed situation that can pull

your hands into the spinning cutter or yank

stock from your hands. Follow the above

instruction at all times or serious personal

injury can occur.

For irregular shaping:

1. DISCONNECT SHAPER FROM POWER

SOURCE!

2. Remove the fence assembly.

3. Choose the appropriate cutter for your appli-

cation and lock it in place.

4. Check the rotation of the cutter.

5. Adjust the spindle height to align your

workpiece to the cutter.

Check that the rub

collar will contact the workpiece edge or pat

-

tern edge (if used).

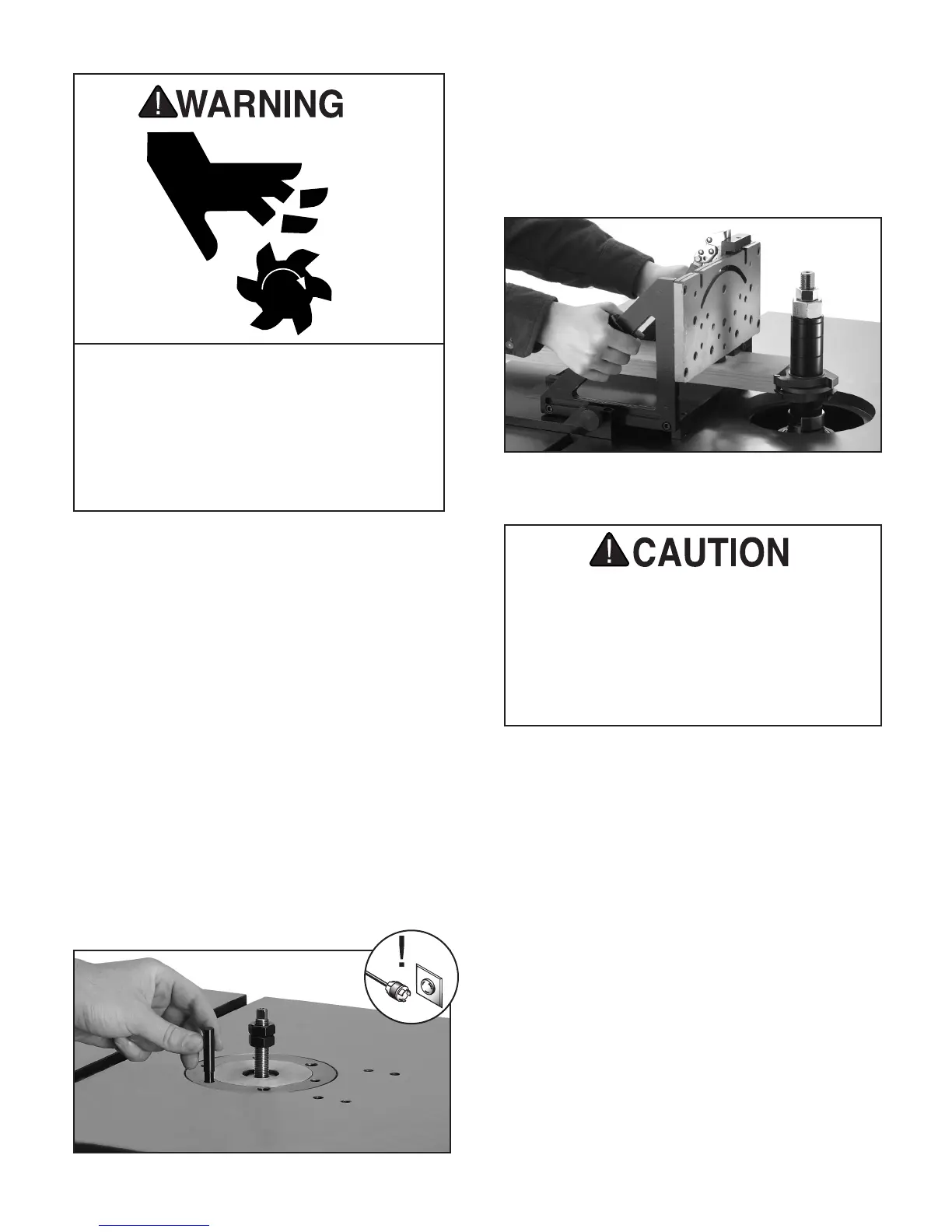

6. Insert a starting pin (Figure 42) into the table

surface, using the pin location that best sup

-

ports your work.

All guards MUST be installed on your shaper

before operating it. Shapers are dangerous

machines that can quickly cause serious

injury if some kind of guard is not used. To

protect yourself, read and follow the entire

instruction manual carefully and do addi-

tional research on shop made guards and

safety jigs.

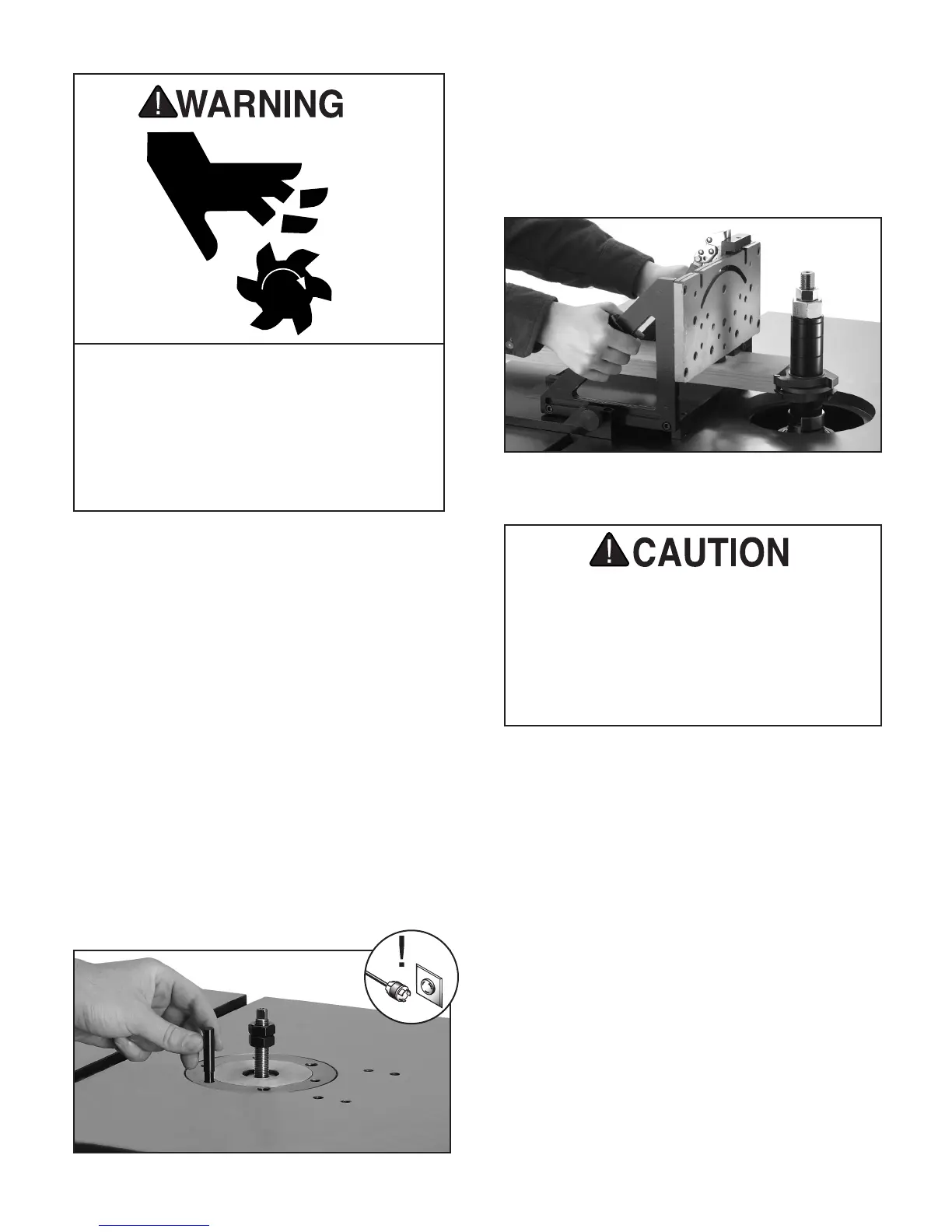

Figure 43. Using safety fixtures while shaping

(guard removed for clarity).

When doing irregular work, use some type

of hold-down fixture and guard such as the

Grizzly Model G3642 Shop Fox

®

Right Angle

Jig (

Figure 43). A good shaper book will pro-

vide many different ideas for making jigs for

almost all shaping operations.

Figure 42. Inserting starting pin.

Loading...

Loading...