Slicer/Applicator

SS-10.DOC:1/26/2007 11:08 AM

Grote Company

19

The following steps detail the procedure for changing to the extended position.

1. Remove the product holders.

2. Remove the bolt in the hole in front of the adjustment block. Loosen the hex head cap

screws and the adjustment jack screws.

3. Remove the pivot bolt and pull the insert (pivot shaft, roller bearing and inner-race

spacer) out of the pivot hole from the outside.

4. Move the pivot block to the extended position and reinstall the insert. Tighten the

pivot bolt into the insert.

5. Tighten the adjustment jack screw and the hex head cap screw. Place the remaining

bolt in the exposed hole on the top of the frame.

6. Adjust the height of the product holder box, the stroke length, and the stroke starting

point.

7. On multiple split-head machines, the lock pin assembly for heads 2, 4, and 6 must be

moved to the extended position whenever the product holder box is moved to the

extended position. Also adjust the roller arm of the limit switch mounted on the lock

pin assembly so that it is tripped near the end of the slicing stroke.

Slice Stroke Adjustment

Check the adjustments of the stroke length and stroke starting point by running at a very slow speed.

The motion of the product holder should be slow enough to allow the relative positions of the blade

and the product holder to be seen. Readjust as necessary until the stroke is centered over the blade

with the proper stroke length

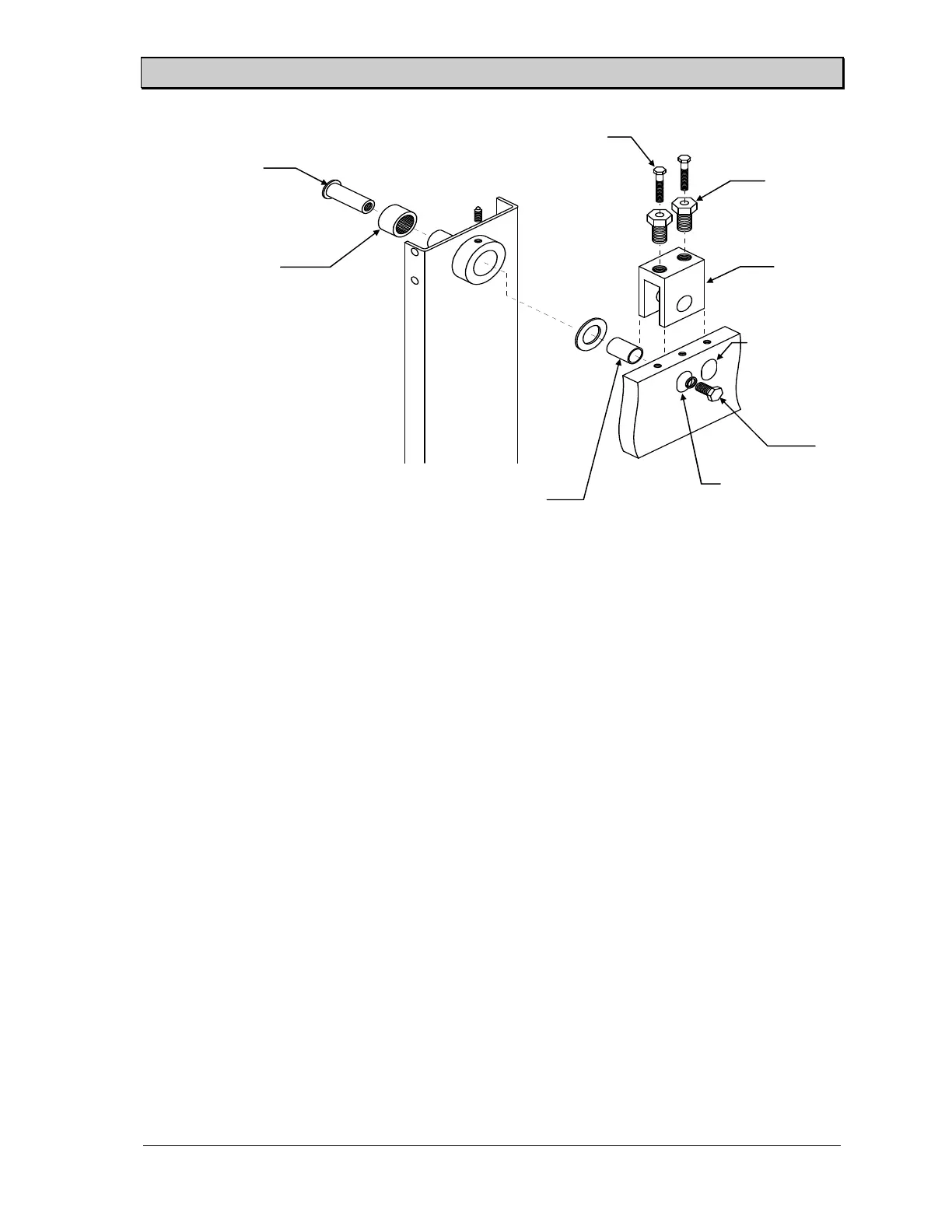

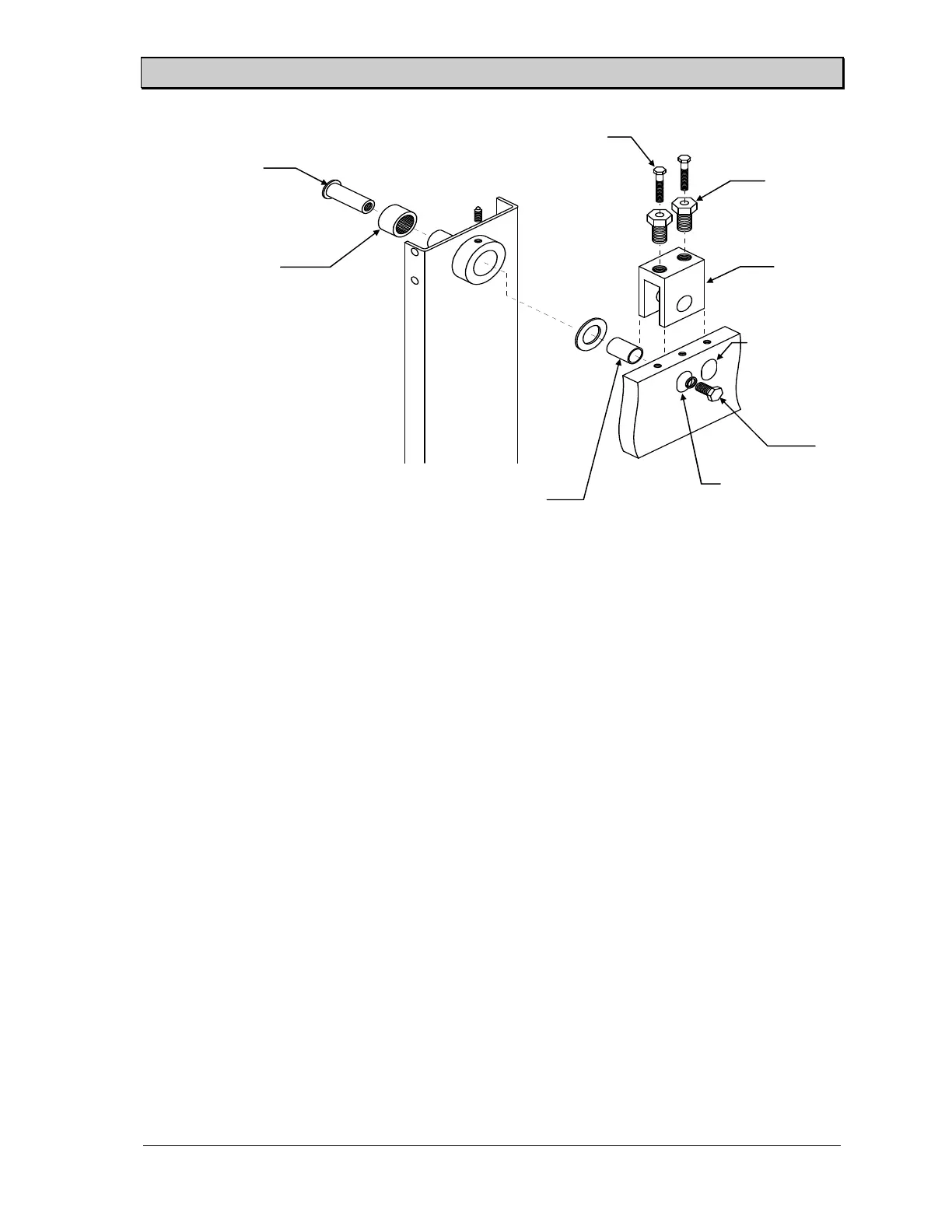

Figure 13. Product Holder Box Pivot Point - Hydraulic Machines

Pivot shaft

Roller bearing

Inner race spacer

Hex head cap screw

Adjustment jack

screw

Adjustment

block

Regular position

Extended

position

Pivot bolt

Loading...

Loading...