Slicer/Applicator

SS-10.DOC:1/26/2007 11:08 AM

Grote Company

7

All-Electric Power System

The slicing heads are driven by an electric servo motor power system. Controls are all

electrical and controlled by a Programmed Logic Controller through an Operator Interface. A

typical single head all-electric slicer is shown in Figure 2.

Figure 2. Typical Single-Head All-Electric Slicer (To Be Provided).

Note: Both types of slicers are described in this manual. When a section applies to only one type

of system, it is identified in the section heading.

Safety Cabinetry

The cutting blade and drive mechanism for the blade are completely enclosed to provide maximum

safety for the operator. Access to the blade is easy with doors and removable covers.

Optionally provided proximity switches sense guard door closure and cut power to the slicer when

one of the doors is opened. The blade drive pulleys coast to a stop if they are running when a door

is opened.

Mechanically interlocked, defeat-proof safety switches are available as an option for guard doors.

These switches act as locks, preventing the doors from being opened until the machine has been shut

off and the blade drive pulleys have stopped rotating. The slicer must have power applied before

these switches will operate and allow the doors to be opened. A Safety Interlock Switch Locations

drawing included with the drawings at the end of the manual shows the location of the interlock

switches.

CAUTION: The safety cabinetry described above prevents an operator from gaining access to

the cutting blade from any position around the machine while the blade is running.

A conveying device under the slicer prevents the operator from access to the cutting

blade from beneath the machine. If the slicer is operated without a conveying

device in place, then steps must be taken to keep personnel from moving under the

slicer while it is operating.

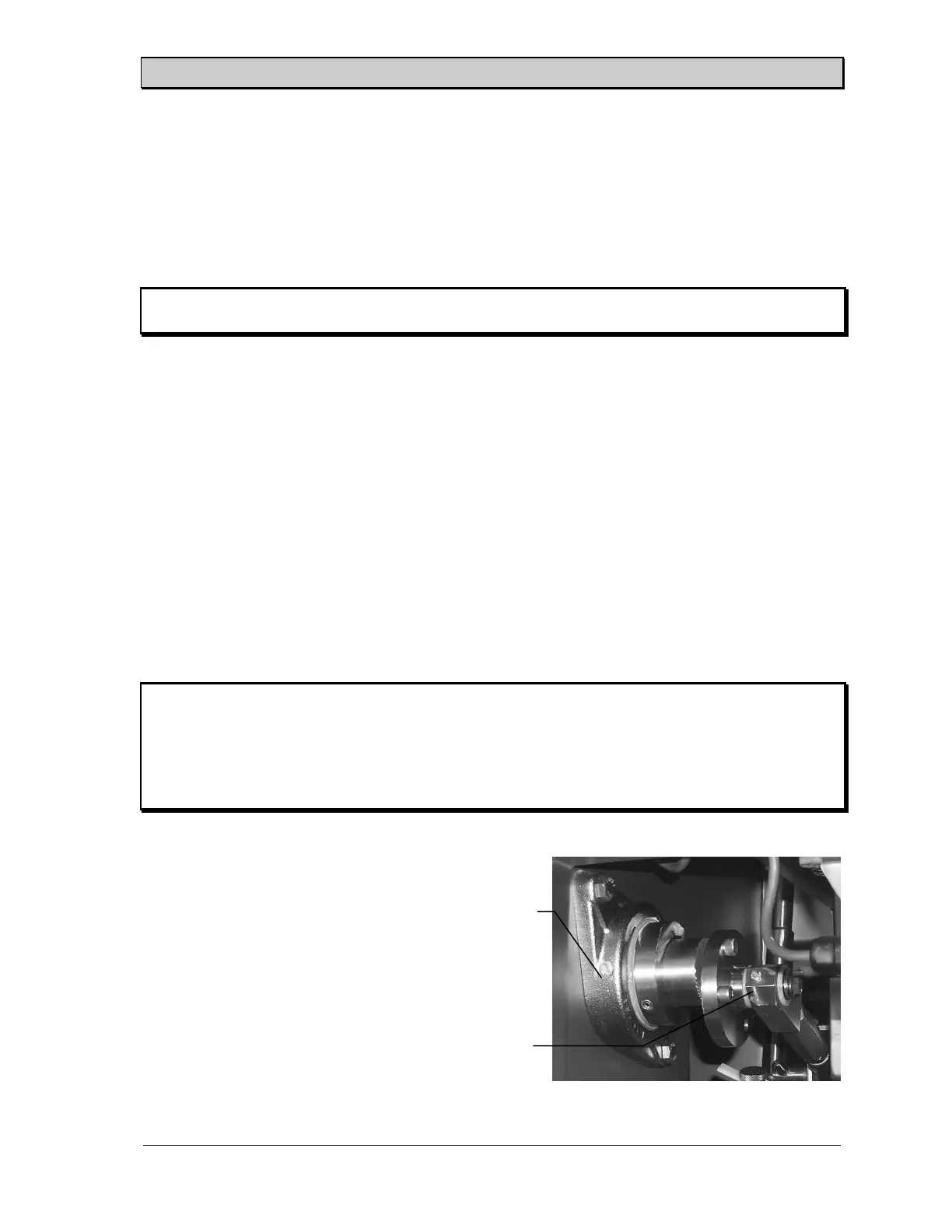

Lubrication –

All Electric Slicers

Each slicing head has two grease points.

One is on the end of the rod connecting the

offset crank to the cluster box and one is on

the crank bearing. Grease all fittings after

each washdown to purge excess water from

the bearings and increase component life.

Use FML-2 Lubriplate or equivalent USDA

approved grease.

Figure 3. Grease Points

Crank

Bearing

Grease

Point

Connecting

Rod Grease

Loading...

Loading...