Slicer/Applicator

SS-10.DOC:1/26/2007 11:08 AM

Grote Company

21

Stroke Speed

Hydraulic Slicers - The speed of the slicing stroke is adjusted with the hydraulic flow-control valve

on the side of the slicer frame.

All-Electric Slicers - The speed of the slicing stroke is adjusted with the key pad on the operator

interface.

Stroke speed should be adjusted so that the cluster moves across the blade at a speed matching that

of the conveyor. Variations to this may be desired and can be determined upon actual application.

The speed of the overall stroke cycle must be fast enough to allow the cluster to be at the original

starting position when it is time to start the forward motion of the next cycle.

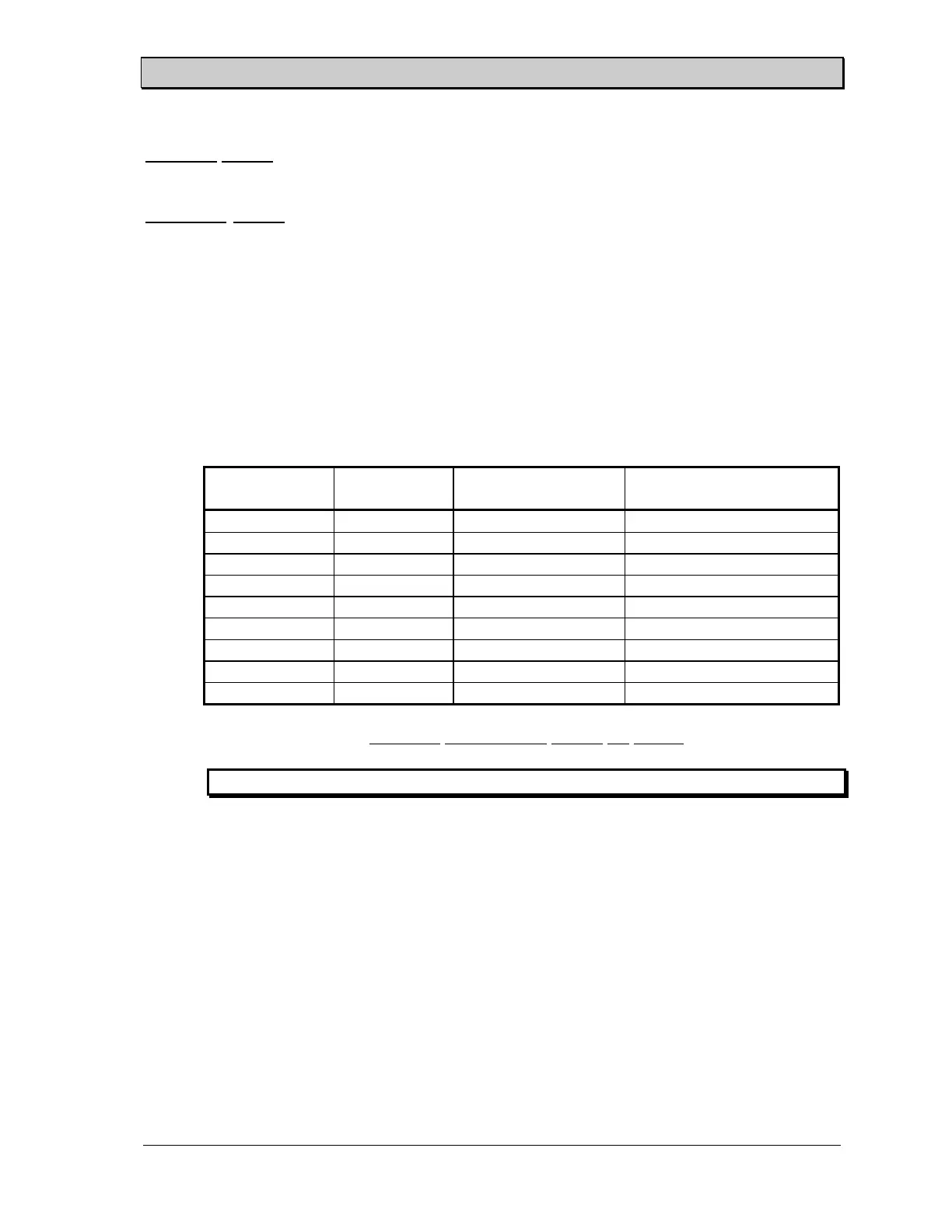

The maximum recommended stroke speed is dependent upon the stroke length. Longer stroke

lengths require more mechanical travel of the cluster assembly thus limiting the allowable number of

strokes per minute. The following table lists the maximum strokes per minute for the listed stroke

lengths.

Stroke Length

in Inches

Product Size

in Inches

Hydraulic Usage in

GPM

Max Recommended

Strokes/Minute

2.0 1.5 5.3 176

2.5 2.0 5.0 168

3.0 2.5 4.8 160

3.5 3.0 4.6 152

4.0 3.5 4.3 144

4.5 4.0 4.1 136

5.0 4.5 3.8 128

5.5 5.0 3.6 120

6.0 5.5 3.4 112

Maximum Recommended Strokes per Minute

Note: The maximum rating of the slicer is 176 strokes/minute.

Other factors that affect the stroke speed are:

1. Shuttle Conveyor - Slicers equipped with a shuttle conveyor should not exceed 120

strokes/minute.

2. Quick Return - The quick return feature becomes largely ineffective at speeds above 70

strokes/minute.

3. Product Pusher - Slicers equipped with a product pusher should not be run at speeds above

140 strokes/minute.

Changing the Thickness Range

Figure 16 shows the adjustment bolts for the slice thickness range and slice gap on standard

thickness trays.

Loading...

Loading...