Chapter 4: Operation

Operating the Auger

CAUTION

DO NOT start/stop the auger while it is under load, this may cause the auger to

“jam”.

CAUTION

Failures may occur if the auger is run full before it has been “polished” during the

“break-in” period.

CAUTION

Be aware of any unusual vibration or noises during the initial start-up and “break-in”

period. If anything unusual is detected, immediately shut down the auger and

disconnect and lock out the power supply before servicing. Visually inspect the

auger periodically during operation.

1. Start the unload. The motor is located on the power head outside the bin on the unload tube. To

figure out the horsepower needed for the equipment, use the horsepower chart.

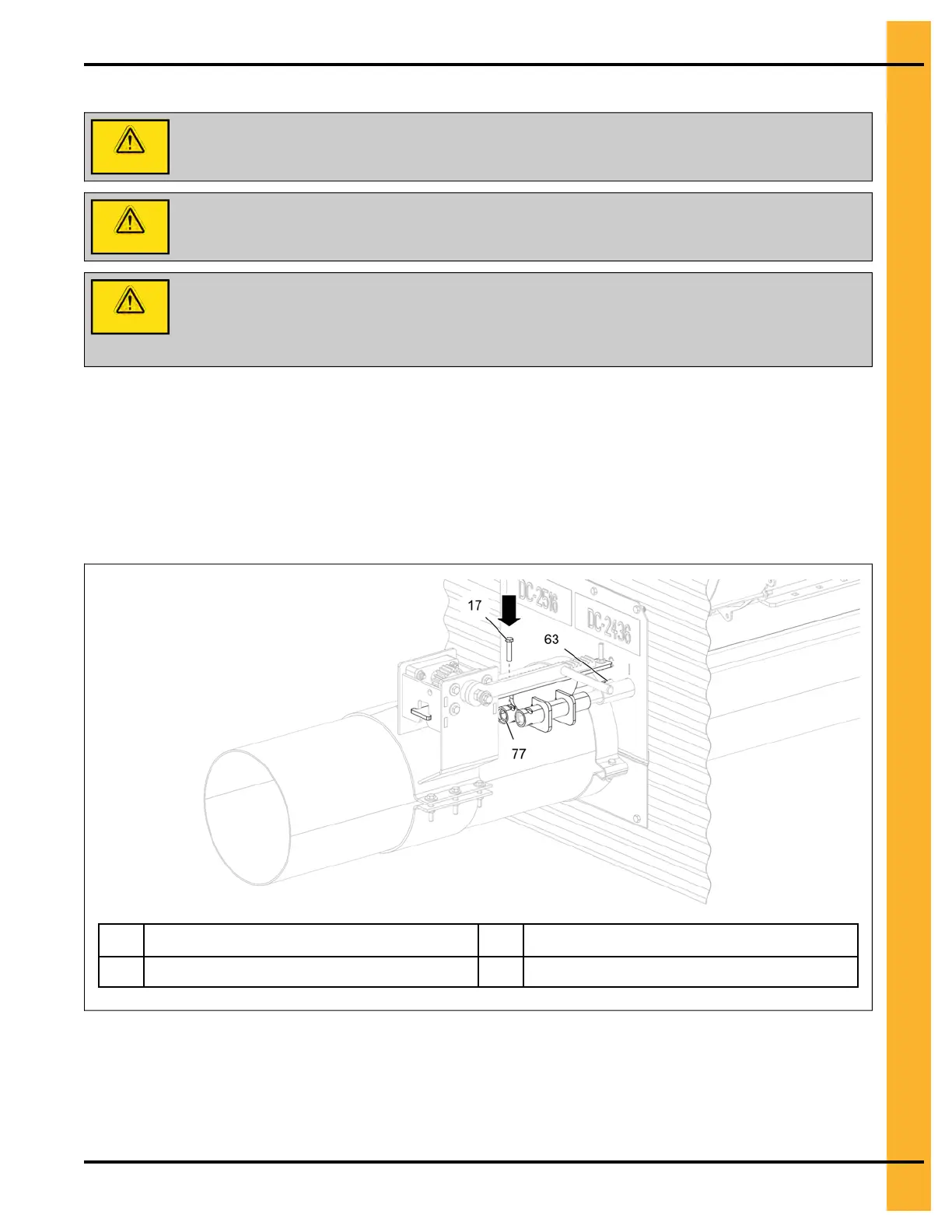

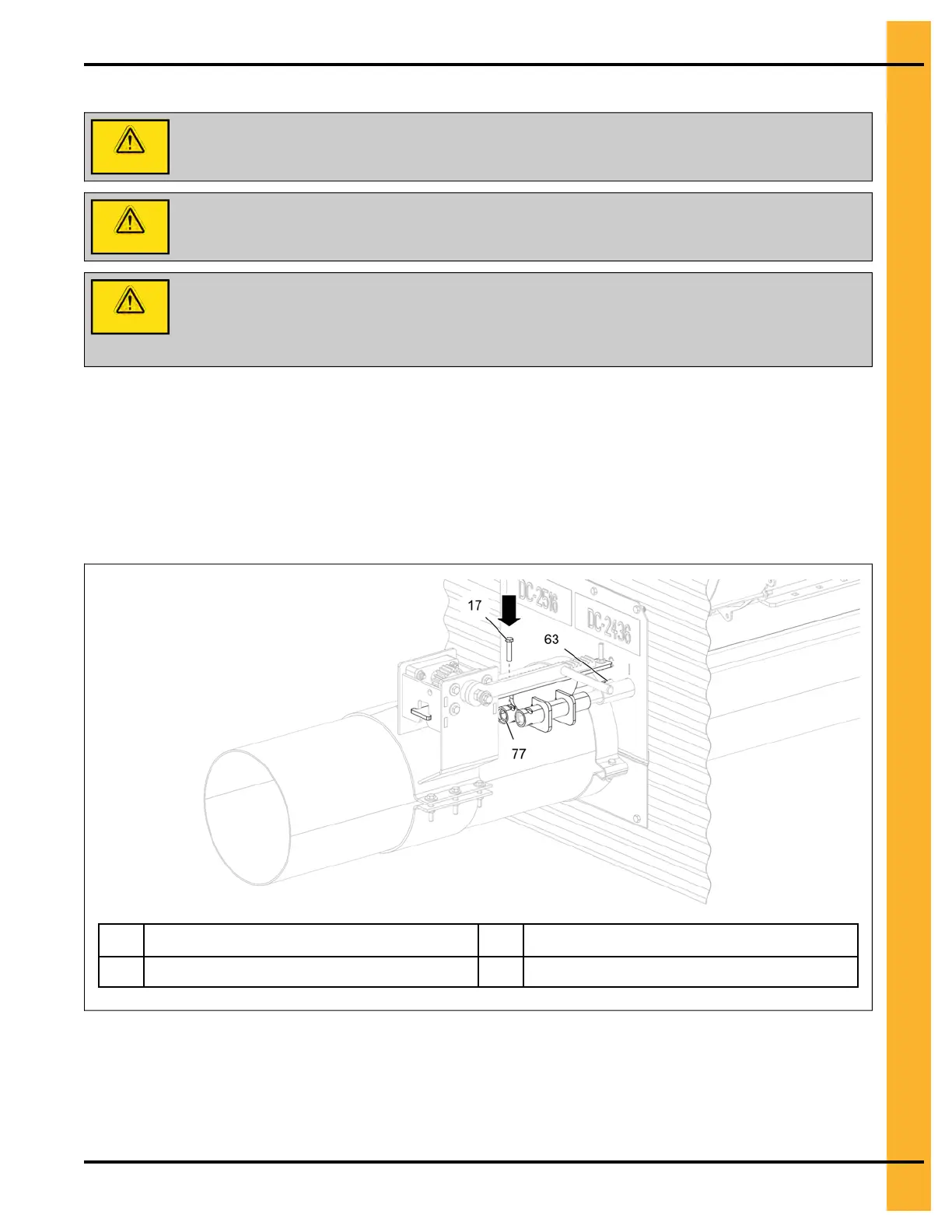

2. Insert the 5/16" x 1-1/2" HHCS bolt (17) through the rack and pinion (77) tube and center well control

rod (63). Also, make sure the 5/16" x 1-1/2" HHCS bolt (17) through the rack and pinion (77) tube

and intermediate well control rod is not inserted.

NOTE: Refer to the decal (DC-2516) on the unload tube for operating assistance.

Figure 4-3 Opening the center well gate

17

5/16" x 1-1/2" HHCS bolt

77

Rack and pinion assembly

63

Center well control rod

3. Using the handle on rack and pinion, open center gate (indicated with “C”) until desired flow is

established. It should not be necessary to open gate more than 3" to 6". Do not open the gate more

than 3" to 6" as the flow of grain into the center well will be at a higher rate than what the unload

system can remove. This will cause the unload to plug or jam.

PNEG-2308 Chain Loop Power Sweep

59

Loading...

Loading...