First-time operation

4.2 Turning on the instrument

Turn on the LCR bridge by

pressing the power switch

1

on the front panel. All

pushbuttons will light up for a

moment, then the instrument

will be ready to operate by

using the pushbuttons and

the knob. In case the push-

buttons and display do not

light up, either the mains

voltage is missing or any of the internal mains fuses are open

(see page 35). The actual measurement results are shown on

the right-hand side of the display, the most important para-

meters on the left-hand side. The components to be tested are

connected to the 4 BNC front panel connectors either directly

or using the appropriate accessories. A 4 mm banana jack is

also provided for a direct connection of the instrument to a

suitable ground potential.

Please note!

Unplug any test adapter or accessory for component

measurements by pulling straight towards you!

The front panel ground connector and the ground

contact of the trigger input are directly connected

to the mains safety ground potential through the

line cord. The outer contacts of the front panel

BNC connectors

20

–

23

(as well as the shields

of any coaxial cables attached) are connected to

the GUARD potential which has no connection to

the safety ground! No external voltages may be

applied to the BNC connectors! The rear panel

interfaces

47

and

48

are galvanically isolated (no

connection to ground)!

Ifthereareunidentiablemessagesonthe display,orifthe

instrument fails to react to operation of its controls: turn it

off, wait a minute and turn it on again in order to trigger a re-

set operation. If the display remains unchanged or operation

impossible,turnitoffandtakeittoaqualiedservicecentre.

(see page 35).

4.3 Line frequency

Prior to any measurements, the line frequency setting must be

set to the applied line frequency, 50 or 60 Hz. If the line frequency

is not set properly, depending on the measurement range and

the line frequency value, instabilities may occur e.g. on the

display. In order to set the line frequency press the SELECT

button

3

, use the SYST menu for accessing MAINS FRQ, use

the knob

6

for selecting the correct value.

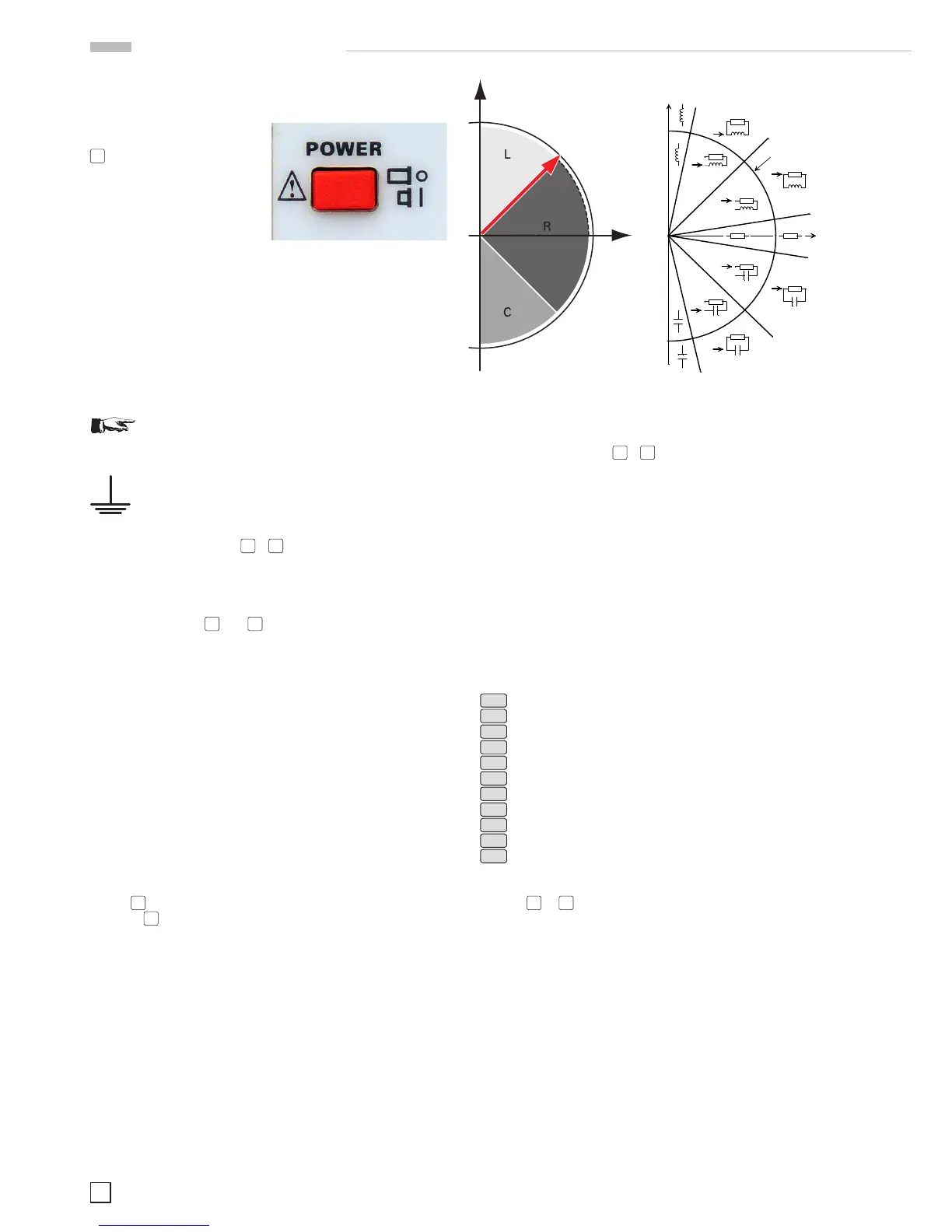

4.4 Measuring principle

In fact, it measures the impedance (|Z|) and the phase angle

(

Θ) of the device under test and, depending on the result,

the component willbe identiedaccording to the drawing

below.

Fig. 4.4: HM8118 Measuring Principle schematic left / detailed pre-

sentation right

In the automatic mode, the HM8118 selects the measurement

function (pushbuttons

28

–

39

) as such as well as the internal

equivalent circuit of the measurement circuit according to the

values measured, either serial (for inductive loads) or parallel

(for capacitive loads). See also chapter 4.8.

4.5 Main measurement and second measurement

value display

The LCR meter HM8118 is able to measure and display two

parameters simultaneously selected from 9 measurement

functions.Therstparameterisrelatedtothe„rstormain

measurement value display“ and the second parameter to the

„second measurement value display“. The following main- and

second measurement values can be displayed:

L-Q

Inductance L and quality factor Q

L-R

Inductance L and resistance R

C-D

Capacitance C and loss tangent D

C-R

Capacitance C and resistance R

R-Q

Resistance R and quality factor Q

Z-

Θ

Apparent impedance (admittance) Z and phase angle Θ

Y-

Θ

Apparent conductance Y and phase angle Θ

R-X

Resistance R and Reactance X

G-B

Conductance G and susceptance B

N-

Θ

Transformer turns ratio N and phase angle Θ

M

Transformer mutual inductance M

The measurement functions can be selected by pressing the

buttons

29

to

39

.

The actual measured series resistance includes all series re-

sistances such as the component leads and the resistance of

series-connected foils in capacitors as well as dielectric losses;

it is expressed by the dissipation factor DF. The equivalent

series resistance (ESR) is frequency-dependent according to

the formula:

ESR = Rs = D/

wCs

where

ω „Omega“ = 2 π f (circular frequency) represents.

Traditionally, the inductance of coils is measured in a series

circuit; however there are cases where a parallel circuit will

yield a better representation of the component. In small „air“

coils mostly the ohmic or copper losses are predominant , hence

the series circuit is the proper representation. The core of coils

with an iron or ferrite core may contribute most of the losses,

the parallel circuit is to prefer here.

Fig. 4.3: On/Off button

Imaginary

Axis

below -- 45° = C

above 45° = L

Real

Axis

phase angle

applied on the red terminal. The bias voltage works only

when the instrument on capacitance measurement

mode.

Measuring function selection

The desired test function is selected by push buttons (12)

and (14). The push button (12) gives access to the main

parameter (R, L or C), The push button (14) allows a

secondary parameter measurement (Q/D, impedance or

phase).

In order to measure D parameter the instrument needs at

first to be set to capacitance measurement mode, on the

other way, Q parameter will be displayed.

Auto-measurement function

The HM8018-2 is able to automatically determine the

component type in most cases. 3 different automatisms

exists: the automatic impedance range selection (see the

section « Auto-ranging»), the automatic mode

(series/parallel) selection (see the section « passive

components »), and the automatic function selection. These

three automatisms are simultaneously activated when the

instrument is set in automatic mode with the RANGE

AUTO key (7). Then the user can change function or mode

that disables their respective automatism. The manual range

selection disables the three automatisms.

When the instrument is on automatic mode the function

choice depends on the impedance module, phase angle as

well as the quality factor .The diagram below shows the

choice made by the instrument.

Calculation functions

Apart from displaying normal values as resistance, inductance or

capacitance, the HM8018-2 can display relative deviations and

percentages. It is not possible to use these calculation modes for

other functions than the three previous values. The deviations

and percentages are displayed in relation to the two stored values

A and B.

The procedure to obtain relative measurement is as follows:

1) Connect the component corresponding to the reference

value.

2) Store the value (memory A) by pressing on the STORE key,

then press the A key.

3) Press on the A key. The indicator -A lights up and the

display shows the value (Measure – A).

A direct percentage measurement is possible, it is only to use the

÷B key instead of the –A key in the previous procedure. Then the

instrument displays the value 100*Measure/B in %.

To obtain a deviation in % proceed as follows:

1) Connect the component corresponding to the reference

value.

Loading...

Loading...