Subject to change without notice

Connecting of components andmeasurement accessories

results.Inordertominimizetheseinfluencesitisnecessary

to compensate for impedance measurement errors caused by

the adapter and the leads.

To compensate for these measurement errors an OPEN and

a SHORT calibration should be performed at the LCR bridge

HM8118. The procedure was described in chapter 6 „Calibra-

tion“. The calibration values obtained during the calibration

procedure will be stored in the LCR bridge HM8118 and remain

valid until the next calibration.

For frequency depending components it is impor-

tant to perform an OPEN resp. SHORT calibration

for each of the 69 test frequencies.

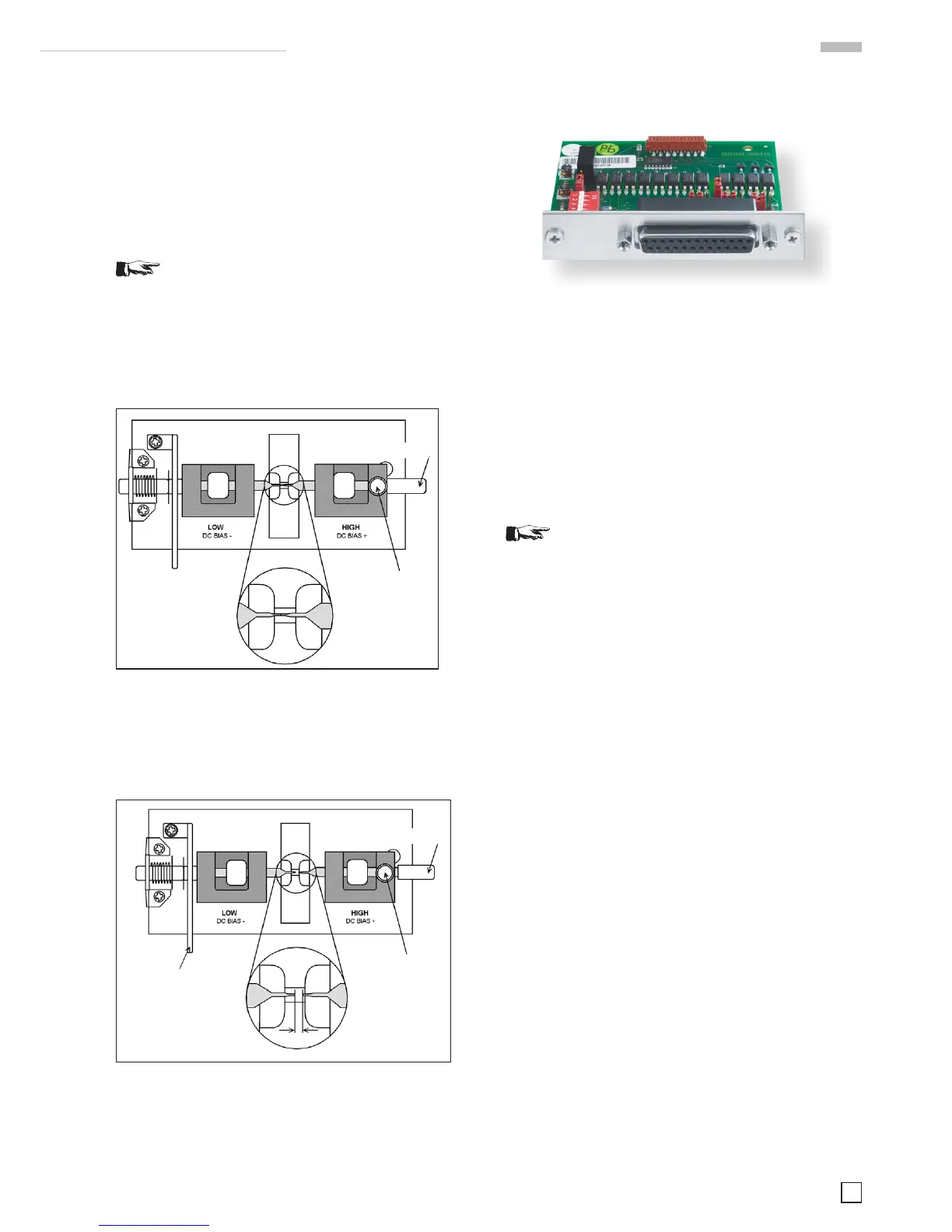

In order to perform the SHORT calibration of the test adapter

HZ188, turn the screw on the righthand side CCW loose. Then

use the pushbutton to push the right contact pin to the left until

both contact pins are electrically connected. Then fasten the

rightcontactpinbyturningthescrewCW.(Seeg.7.9)

10

Änderungen vorbehalten

Für den „Kurzschlussabgleich“ ist bei dem Messadapter

HZ188 die Schraube auf der rechten Seite gegen den Uhr-

zeigersinn zu lösen und anschließend der rechte Kontaktstift

mit der Taste nach links zu drücken, bis beide Kontaktstifte

elektrisch verbunden sind. Danach ist der rechte Kontakt-

stift durch drehen der Schraube im Urzeigersinn zu xieren

(siehe Bild 2).

Bild 2 „Kurzschlußabgleich“

Screw

Locked

Lever

Fig. 7.9: SHORT circuit with HZ188

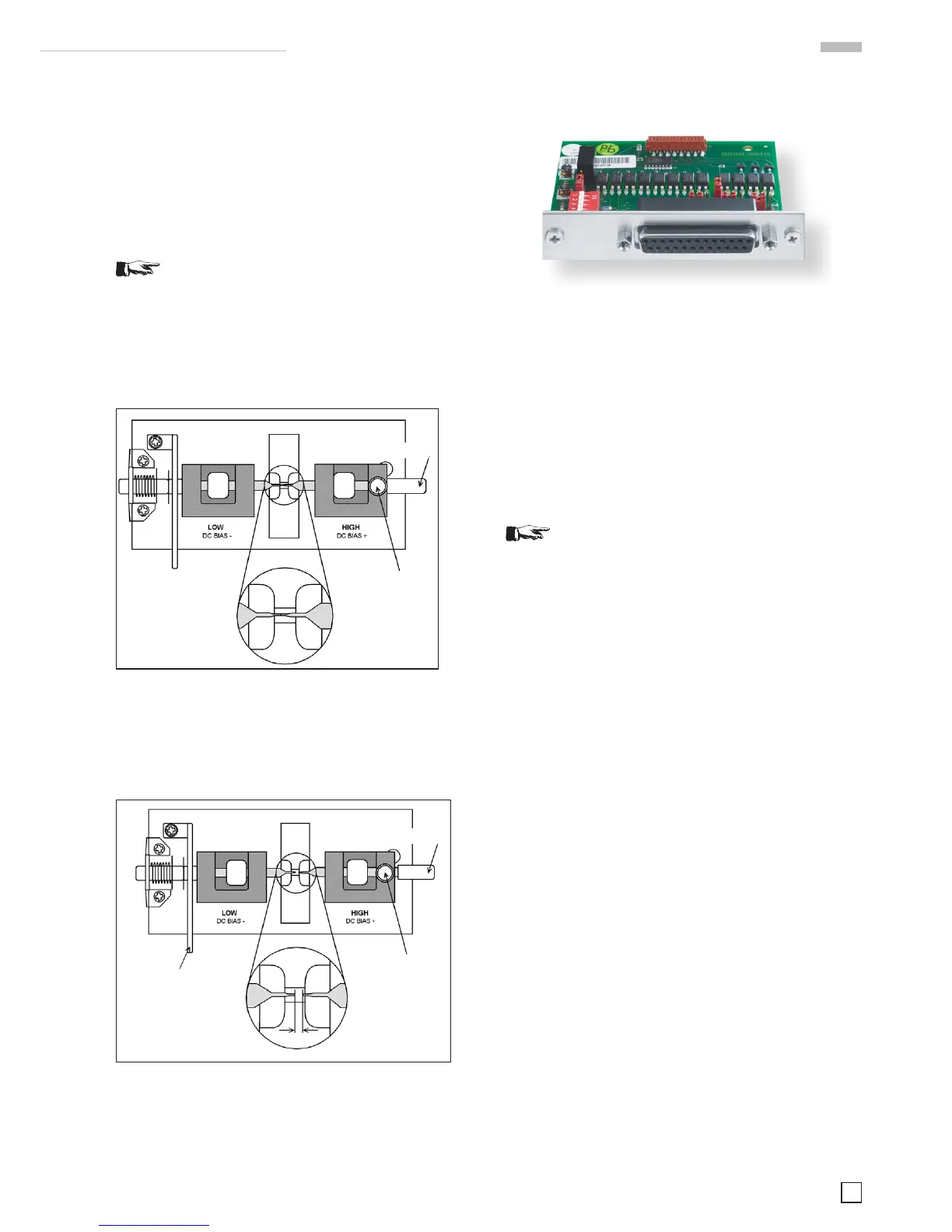

To perform an OPEN calibration turn the screw on the righthand

side CCW and push the right contact pin so far to the right that

both contact pins are apart. The distance between both pins

should equate the length of the SMD component to be mea-

sured.ThenfastenthescrewbyturningitCW(seeg.7.10).

10

Änderungen vorbehalten

Für den „Kurzschlussabgleich“ ist bei dem Messadapter

HZ188 die Schraube auf der rechten Seite gegen den Uhr-

zeigersinn zu lösen und anschließend der rechte Kontaktstift

mit der Taste nach links zu drücken, bis beide Kontaktstifte

elektrisch verbunden sind. Danach ist der rechte Kontakt-

stift durch drehen der Schraube im Urzeigersinn zu xieren

(siehe Bild 2).

Bild 2 „Kurzschlußabgleich“

Screw

Lever

Without SMD

Component

Fig. 7.10: OPEN calibration with HZ188

7.5 Option HO118 binning interface for

component sorting

Fig. 7.11: Optional accessory HO118 binning interface.

A bining interface (25-pin interface) is especially useful in a

production environment:

– for incoming inspection of components

– for the selection of components within tolerance limits

– and if frequently components of similar values have to be

tested.

The binning interface for the LCR bridge HM8118 allows opera-

tion with external hardware which sorts components according

to the measurement results of the HM8118. There are control

outputs for 8 BINs as well as further control outputs (ALARM,

INDEX, EOM, TRIG).

We recommend installing the HO118 at the factory

because the instrument has to be opened which would

entail the loss of warranty.

7.5.1 Specication

Output signal:

Negative TRUE, open collector, opto-isolated, selectable pull-

ups.

Measurement modes:

When the HM8118 is used for binning, the number of measure-

ment modes is limited to the necessary modes for characteri-

zing components. These modes can be selected:

– R-Q: Resistance-Quality factor

– C-D: Capacitance-Dissipation factor

– L-Q: Inductance-Quality factor

Kind and number of BINs:

– pass BINs: BIN 0...5 for primary parameters

– fail BINs: BIN 6 for secondary parameters, BIN 7 is destined

for general failures

– maximum current at an output voltage of 1 V is 15 mA (open

collector outputs)

Index:

Analog measurement complete

Measurement complete:

Measurement completed successfully.

Alarm:

Errornotication.

External trigger:

Opto-isolated, selectable pull-up, pulse width > 10µs.

Itispossibletosetup9binningcongurationswiththeSave/

Recallfunction.Thebinningcongurationsmayberemote-con-

Locked

Loading...

Loading...