f-4 HT4400 Instruction Manual

2

Mild Steel

O

2

Plasma / O

2

-N

2

Shield

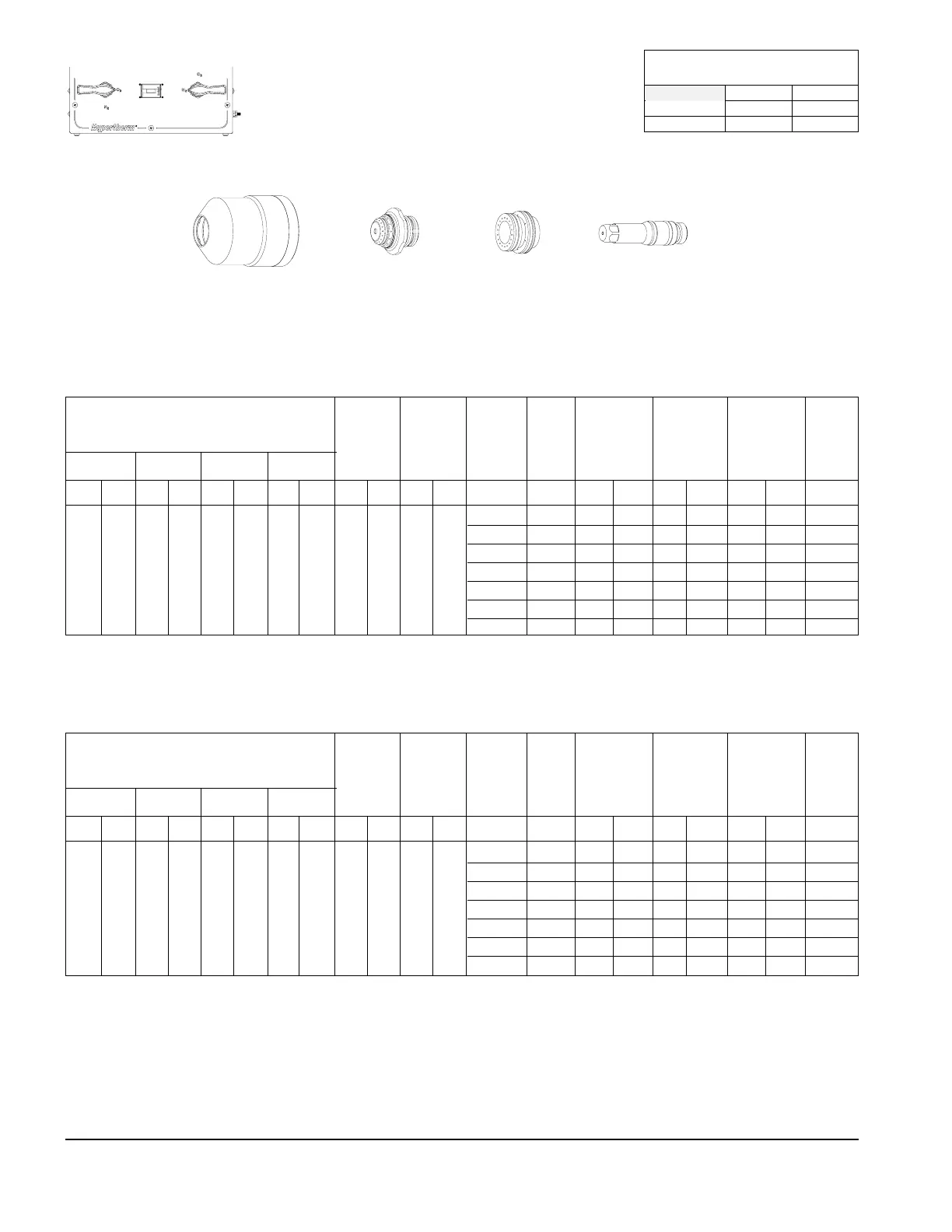

200 Amps

Flow Rates @ 120 psi (8.3 bar)

(scfh / slh)

N

2

O

2

Preflow 180.8 / 5118 57.2 / 1620

Cutflow 123.4 / 3492 111.3 / 3150

120786

Retaining Cap

120787

Nozzle

120791

Swirl Ring

120793

Electrode

Minimum inlet pressures remain at one setting of 120 psi (8.3 bar) for all material thicknesses.

Approximate pressures while cutting in RUN mode: PG1 56

PG2 36

1/4 120 .125 3 160 4060 .250 6 0.5

3/8 120 .125 3 100 2540 .250 6 0.5

1/2 125 .157 4 80 2030 .314 8 0.7

5/8 130 .157 4 70 1780 .314 8 0.9

3/4 135 .188 5 55 1400 .375 10 1.2

7/8 135 .25 6 45 1140 .500 13 1.5

1 140 .25 6 35 889 .500 13 2.5

ENGLISH

Material

Thickness

Plasma PlasmaShield Shield

MV1 MV2 MV3 MV4 MV5 MV6 MV7 PG1 PG2 PG1 PG2 inches Volts in. mm ipm mm/m in. mm seconds

Test

Preflow

Verify

(psi)

Test

Cutflow

Verify

(psi)

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce

Height

Pierce

Delay

Time

Test Preflow and Cutflow Adjust

(psi)

37 3 5 7 18 27 38 2343 3536

6 120 3 .125 4301 169 6 .250 0.5

10 120 3 .125 2419 95 6 .250 0.5

12 125 4 .157 2151 85 8 .314 0.7

15 130 4 .157 1851 73 8 .314 0.9

20 135 5 .188 1331 52 10 .375 1.2

22 135 6 .25 1155 46 13 .500 1.5

25 140 6 .25 903 36 13 .500 2.5

METRIC

Material

Thickness

Plasma PlasmaShield Shield

MV1 MV2 MV3 MV4 MV5 MV6 MV7 PG1 PG2 PG1 PG2 mm Volts mm in. mm/m ipm mm in. seconds

Test

Preflow

Verify

(psi)

Test

Cutflow

Verify

(psi)

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce

Height

Pierce

Delay

Time

Test Preflow and Cutflow Adjust

(psi)

37 3 5 7 18 27 38 2343 3536

Loading...

Loading...