Operation

220 810060 Instruction Manual XPR170

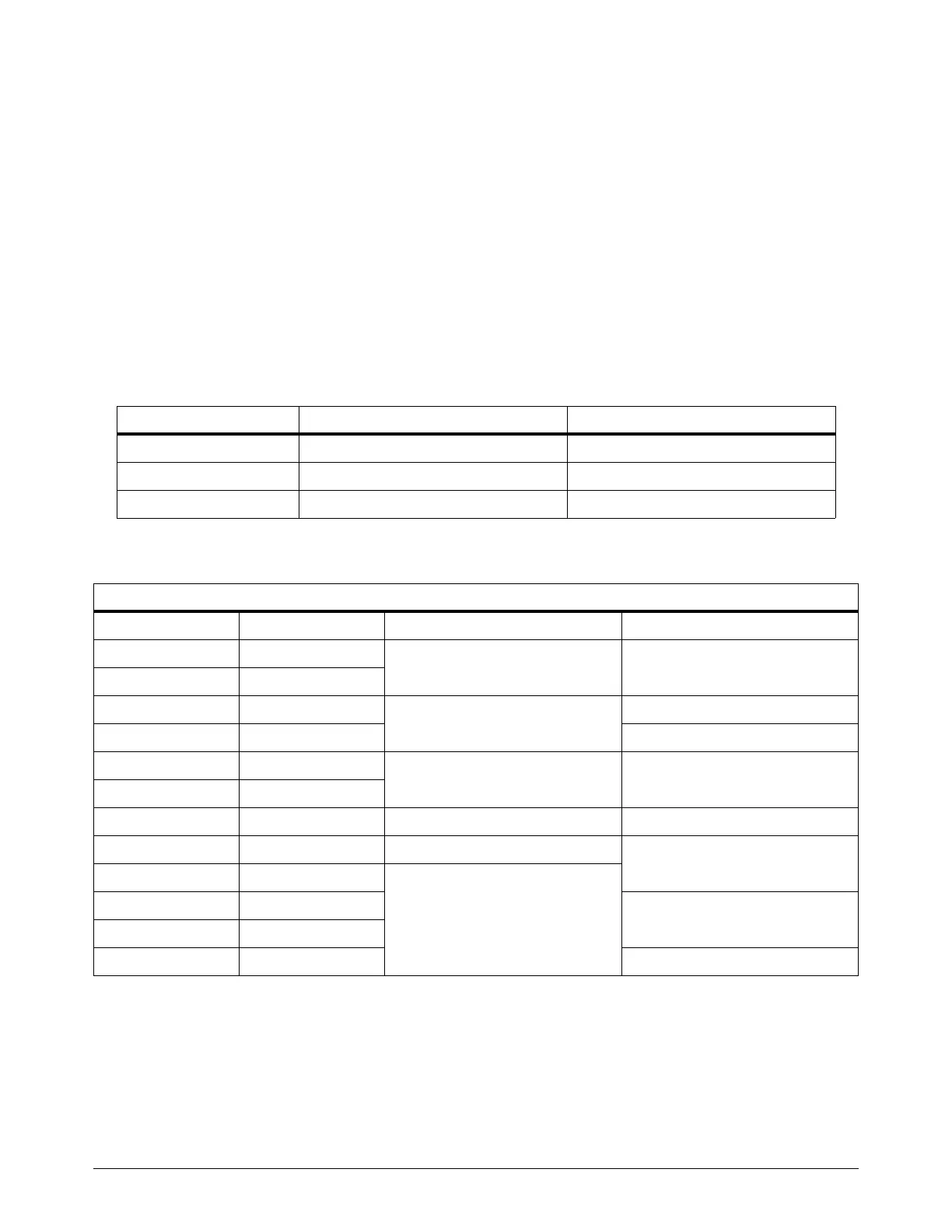

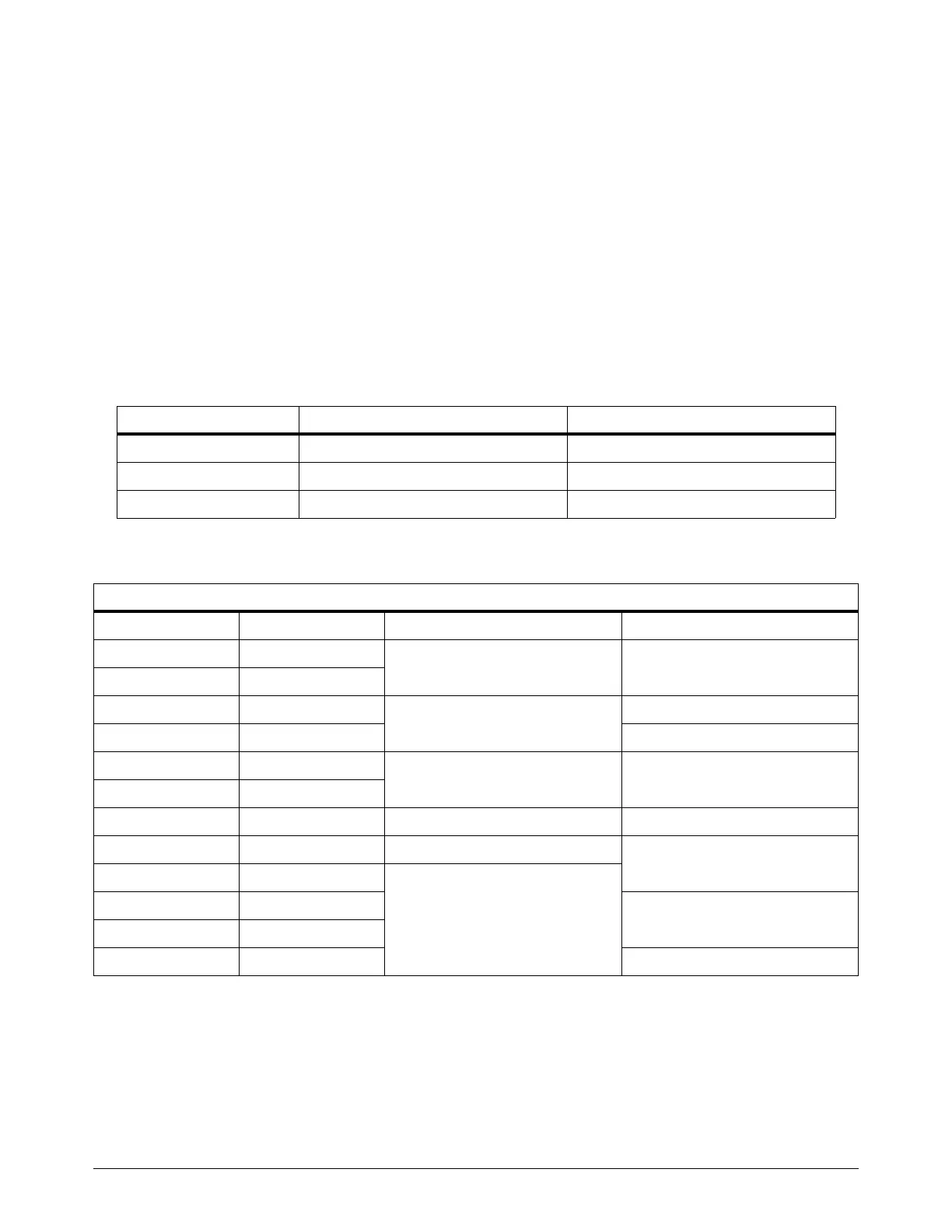

Aluminum

HyDefinition (HDi)

vented processes

In addition to high-quality stainless steel cuts (refer to Stainless steel on page 219), the N

2

and mixed-fuel gas HyDefinition consumables can be used to produce high quality cuts on

aluminum.

HyDefinition

mixed-fuel gas

processes

OptiMix-equipped systems let operators use mixed-fuel gas processes for aluminum

cutting.

The OptiMix gas connect console has a 3-gas mixer that mixes H

2

, Ar, N

2

. The cutting

system chooses an optimized combination of 3 gases or 2 gases (H

2

, Ar) based on the

thickness of the metal to be cut.

HyDefinition vented

water injection

processes

VWI processes use a low flow rate of water through the shield line (instead of shield gas).

A process that uses water as a shield fluid is sometimes known as a “wet” process.

For aluminum, wet processes generally produce a smoother edge than “dry” processes.

Additionally, VWI lets operators get:

• A sharp top edge of the cut

• A smooth cut edge

• Excellent cut-edge angularity

Loading...

Loading...