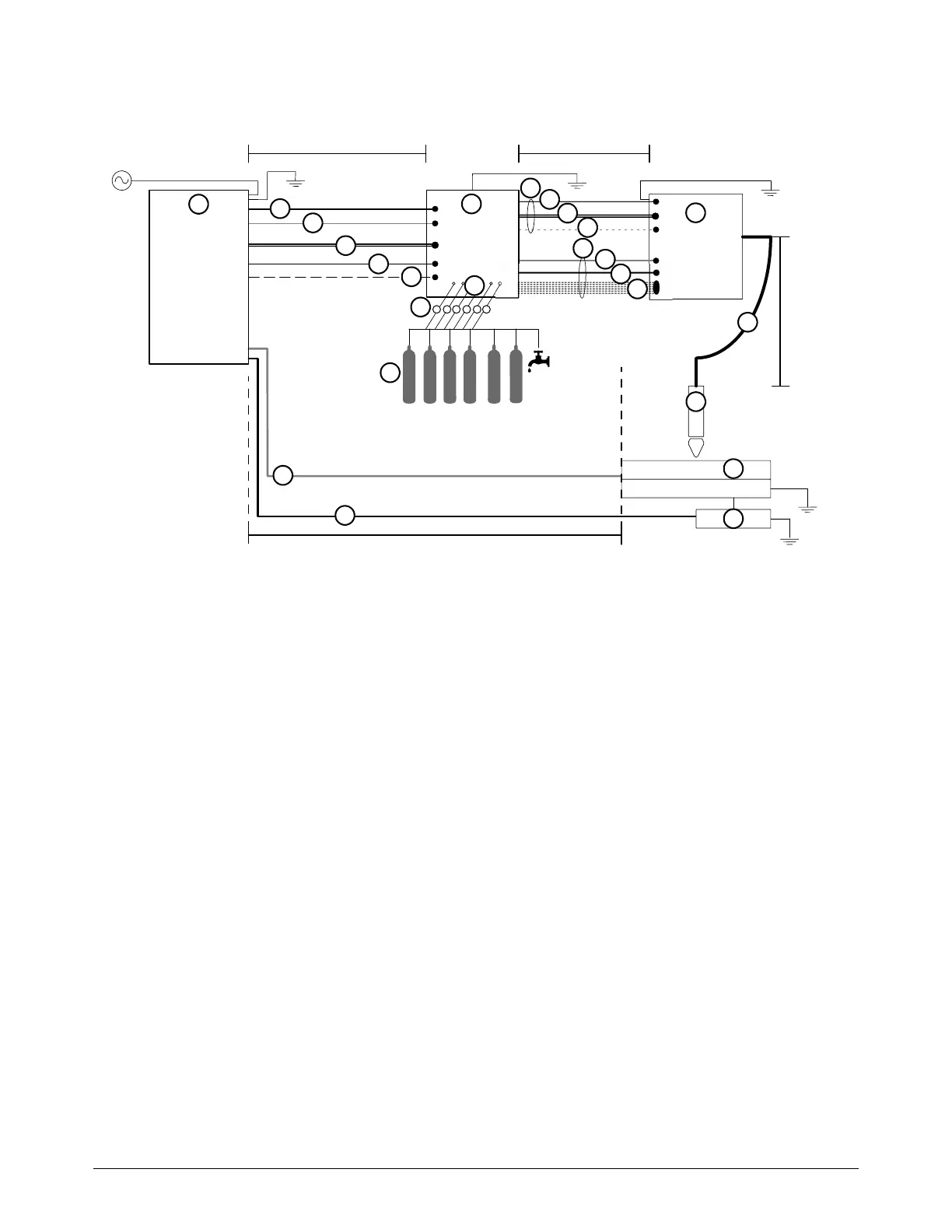

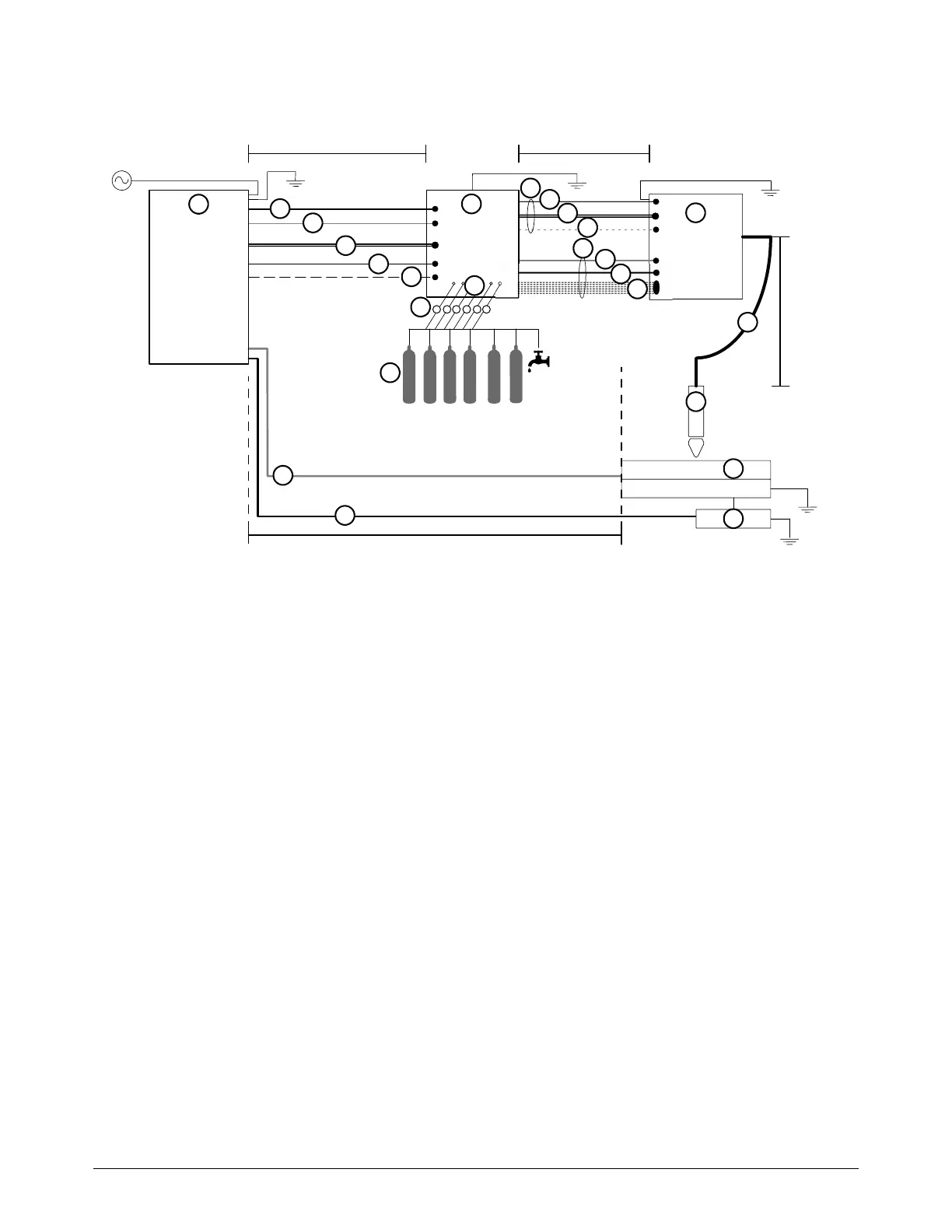

1 Computerized numeric control (CNC) lead

2 Work lead

3 Controller area network (CAN) cable

4 Power cable (120 VAC)

5 Coolant hoses (1 supply, 1 return)

6 Pilot arc lead

7 Negative lead

8 Pilot arc and coolant hose set assembly

a Pilot arc lead

b Coolant hose set (1 supply, 1 return)

9 Power, CAN, 3-gas assembly

c Power cable (120 VAC)

d CAN cable

e 3 gas hoses (Core)

10 Torch lead

11 Regulators

Position a gas regulator within 3 meters (10 feet)

of the gas connect console or take actions to

adjust inlet gas pressures to tolerances specified

in the process gas requirements.

12 Hoses for supply gases

13 Gases Core: O

2

, N

2

, and air

Loading...

Loading...