8.5 Greasing method

8-10

8. Maintenance and Inspection

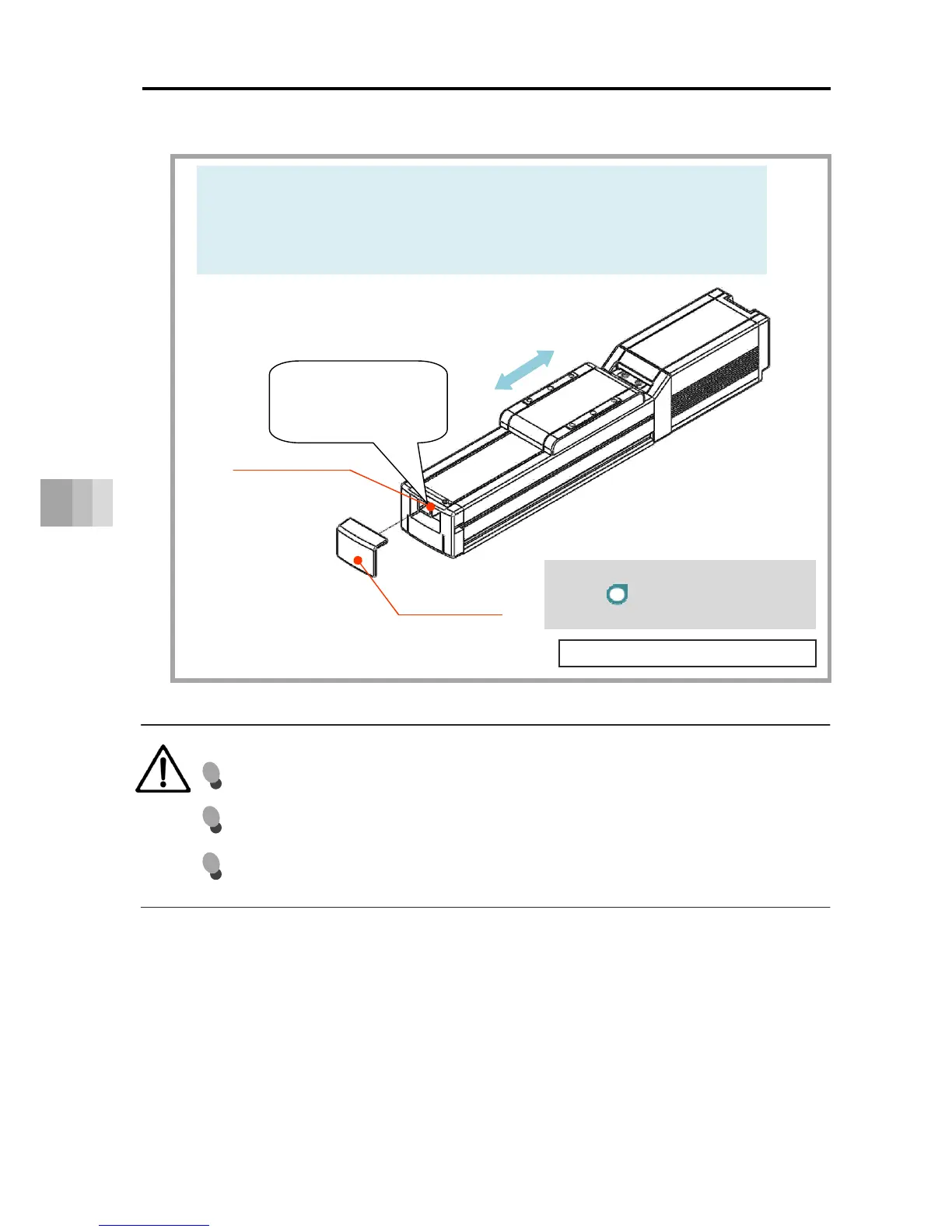

(2) Greasing method: Ball screw/guide (supply to both through grease fitting)

(1) Remove the sheet clamp. (Refer to page 8-7 for the removal method)

(2) Move the slider to the non-motor side.

(3) Lubricate using a grease gun through the grease fitting (φ3.5).

(4) Move the slider full-stroke to apply the grease thoroughly.

Caution

Supplying too much grease may increase sliding resistance.

This may increase motor load and result in decreased performance.

If the grease enters your eye, immediately see a specialist physician for appropriate

care.

After finishing the grease replenishment, wash your hands carefully with water and

soap to rinse the grease off.

Sheet clamp

Grease fitting

(φ3.5)

Slider type greasing method

Grease gun

lubrication

(1.0 to 2.0cc)

* To release the brake,

refer to

Brake release method

(page 3-10)

Loading...

Loading...