74

9. Maintenance and Inspection

9.10 Replacing the Motor

9.10.1 Motor Coupling Type

SA5C, SA6C

[Items Required for Replacement]

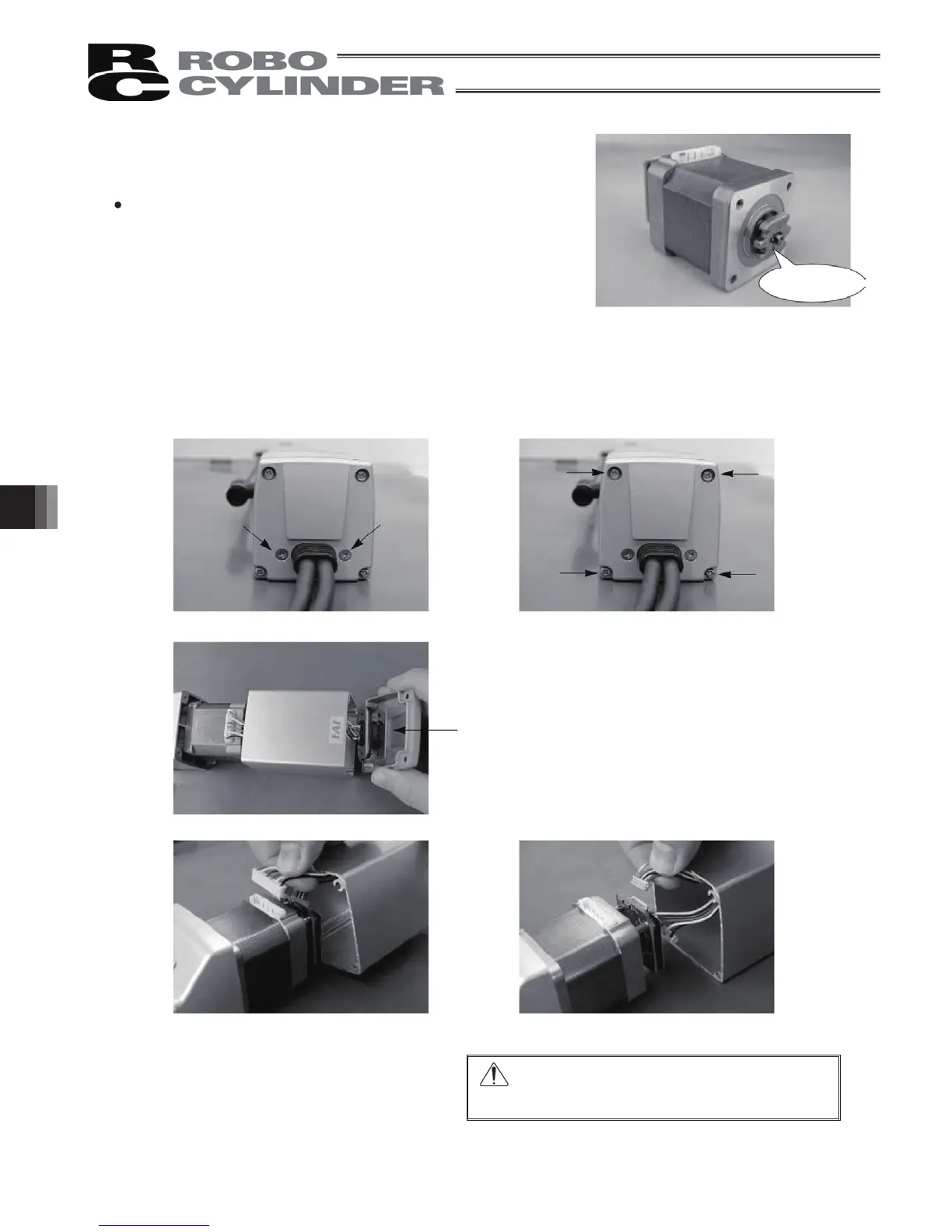

• Replacement motor M-P2SA5C-IAP42N-MB-CO (for SA5C)

M-P2SA6C-IAP42N-MB-CO (for SA6C)

(with a coupling on the motor shaft: see the photograph at the right)

• Allen wrench set

• Phillips screwdriver

• Grease (Kyodo Yushi’s Multemp LRL3 or equivalent)

[Procedure]

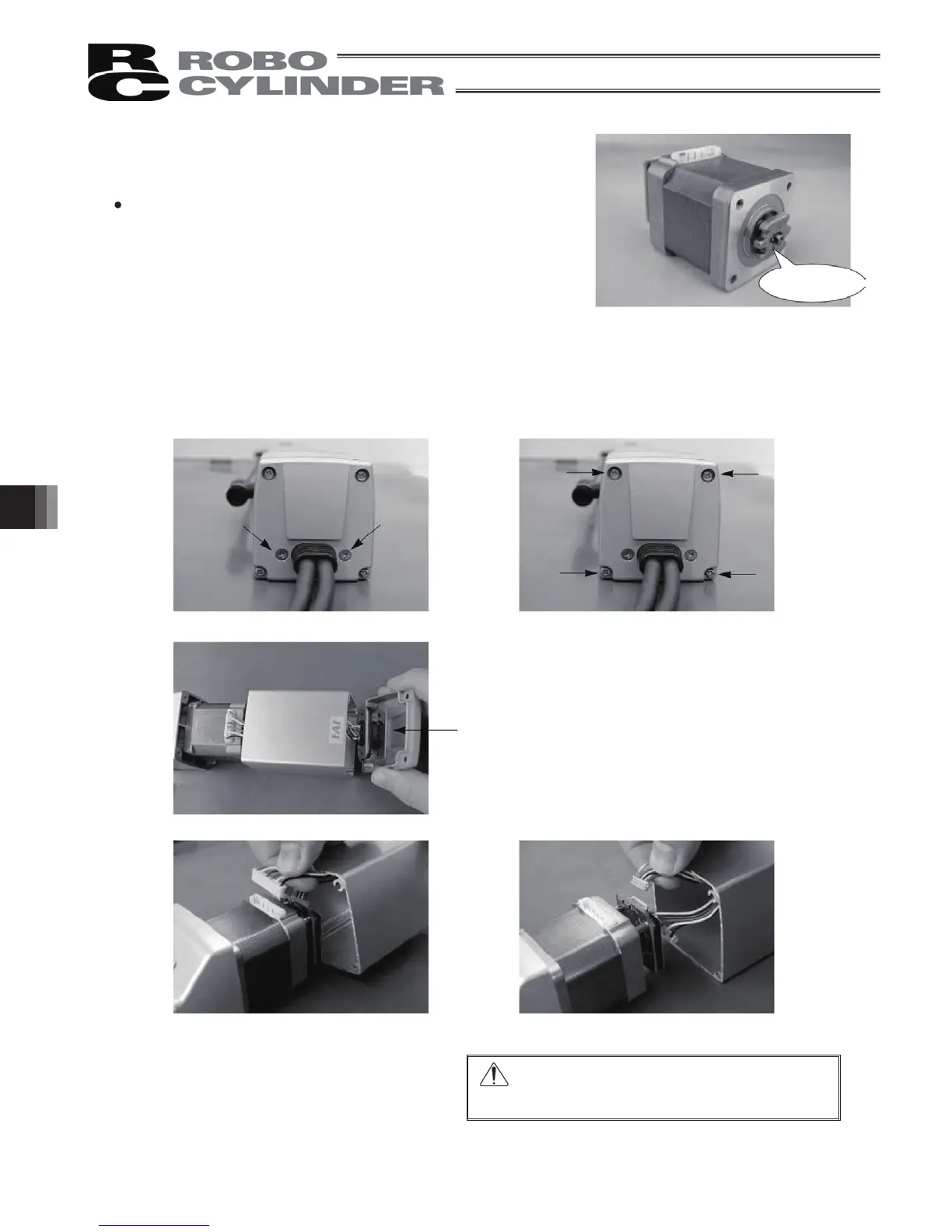

1) After removing the flat countersunk-head screws (M3 × 8, 2 pcs.) affixing the cable ends on the motor-end cap,

remove the pan-head screws affixing the motor-end cap.

.

Caution: Do not apply a force to the encoder

by touching it directly..

• Pan-head screws (M3 × 80, 4 pcs.)

• Flat countersunk-head screws (M3 × 8, 2 pcs.)

3) Pull out the motor connector. 4) Pull out the encoder connector.

Coupling

2) Push in the cable-end molding to create a slack along the inner cable

Push in the molding as far as possible

Loading...

Loading...