101

10. Appendix

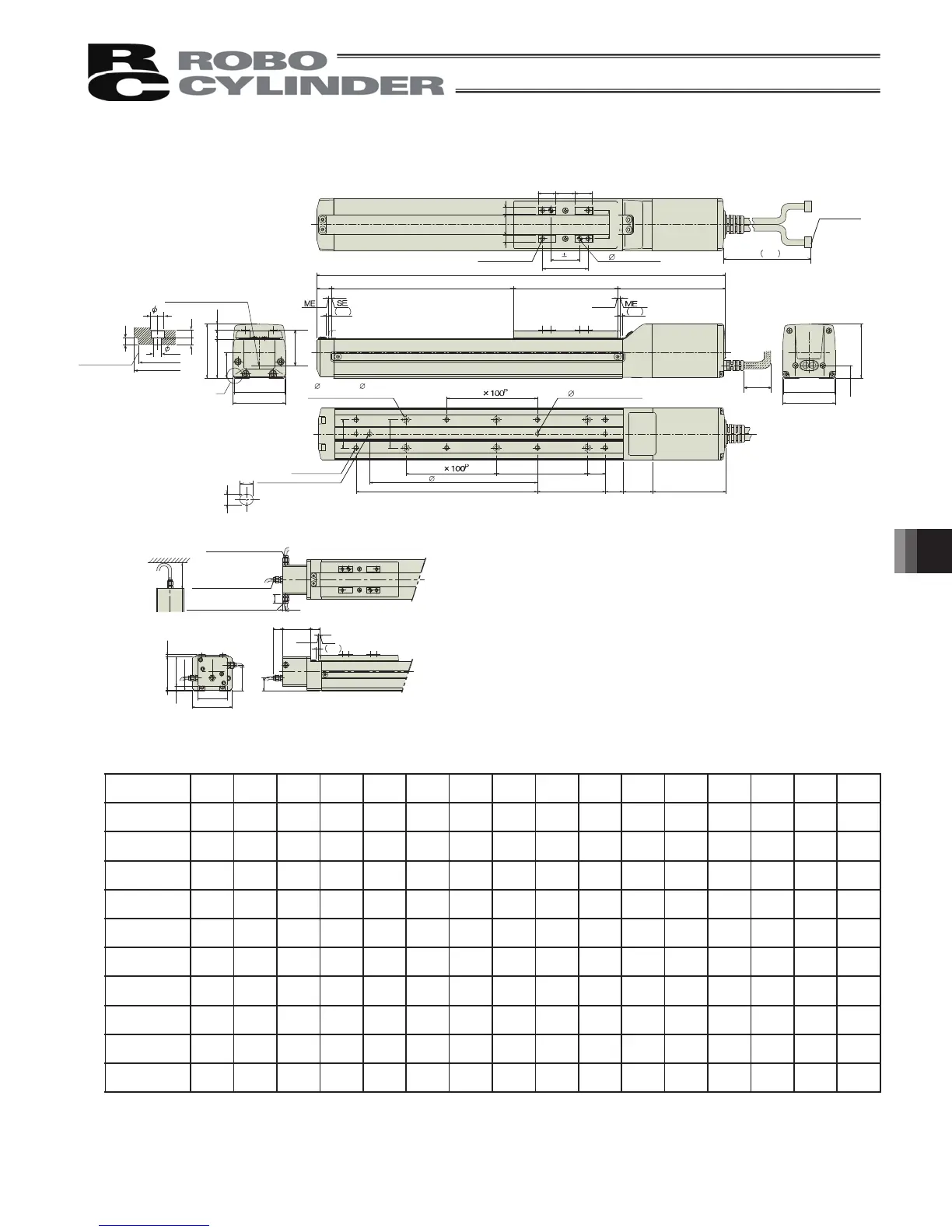

823 8

19.5

21

19.5

31

50

2.2

3

119115

16

2.7

3.1

L

13.8

59.5

56

58

28

43

10

6.5

59.5

56

A

58

50

240

ME

SE

14.3

41.7

13.3

18.5

3.1

2.7

18.5

3.5

37.5

6.5 43

48.5

1

43

58

13.3

5.1

8

4.5

4.5

5

5

56

58

32

0.02

B

C

0

+0.012

4

5

40

20

31

31

100

8133

19.5

A75

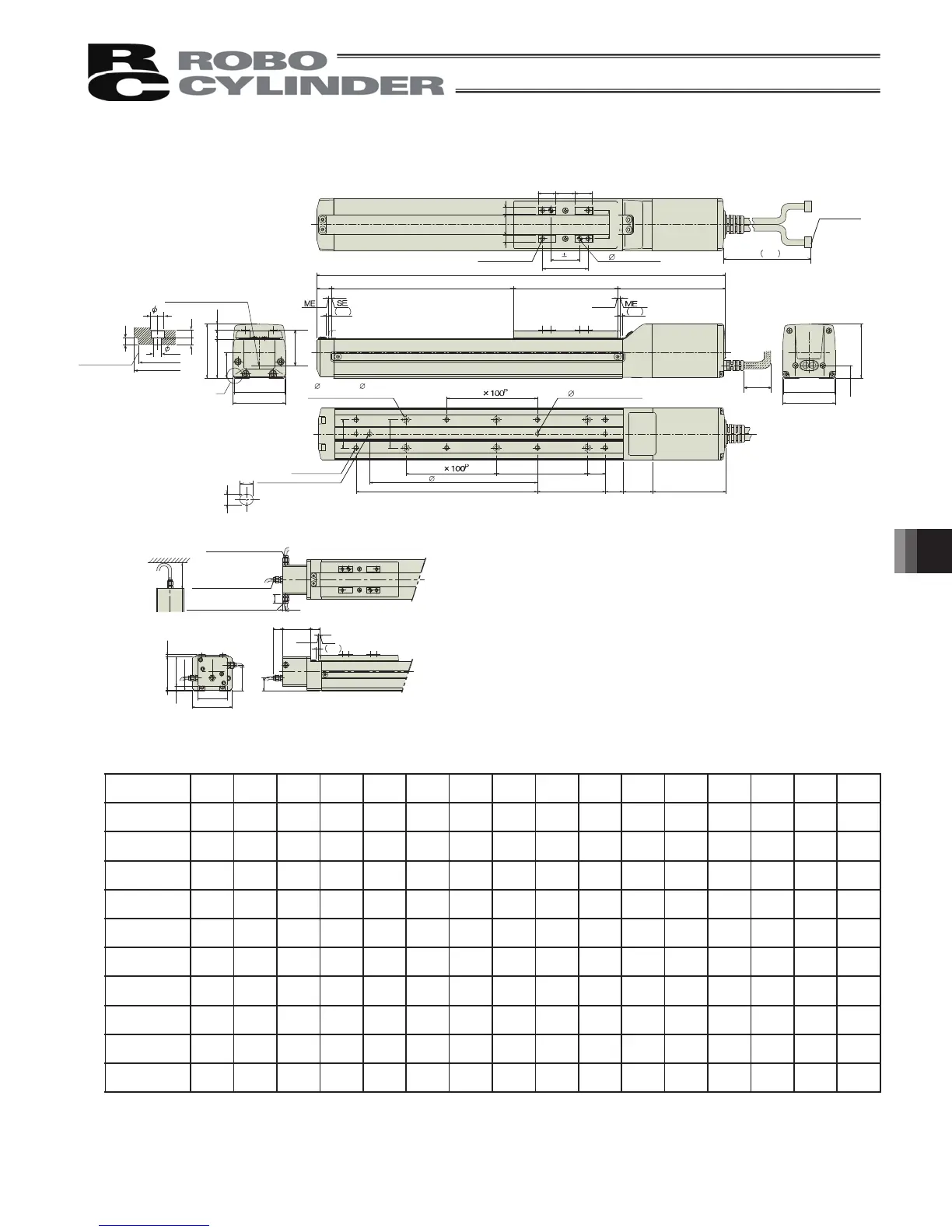

50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800

L 300 350 400 450 500 550 600 650 700 750 800 850 900 950 1000 1050

A 0 100 100 200 200 300 300 400 400 500 500 600 600 700 700 800

B 0001122334455667

C 0011223344556677

D 4 6 6 8 8 10 10 12 12 14 14 16 16 18 18 20

E 2333333333333333

F 44668810101212141416161818

H 0111111111111111

P 0 85 85 185 185 285 285 385 385 485 485 585 585 685 685 785

Weight [kg] 1.8 2.0 2.1 2.2 2.4 2.5 2.7 2.8 2.9 3.1 3.2 3.4 3.5 3.6 3.8 3.9

Stroke

10.1.2 RCP2-SA6C

Reference position for

Ma moment offset

Detail view of A

(installation hole and

reference surface)

F- 4.5 through, 8, counterbore depth 4.5

(from opposite side)

H-oblong hole, depth 5.5 from

bottom surface of base

BE: Brake cable exit

direction, end

BL: Brake cable exit

direction, left

BR: Brake cable exit

direction, right

Brake dimensions

100 or more

Cable joint

connector

4-M5, depth 9

2-

5H7, depth 6

Home

Stroke

E- 4H7 depth 5.5 from

bottom surface of base

P(pitch of 4 holeandoblonghole)

Detail of oblong hole

(Tolerance

between reamed

holes 0.02)

Reference surface

D-M5, depth 9

ME : Mechanical End

SE : Stroke End

* The brake-equipped type is longer in 40mm

(53.3mm for cable end side eject type) and heavier in 0.4kg.

Loading...

Loading...