76

9. Maintenance and Inspection

7) Install a new motor.

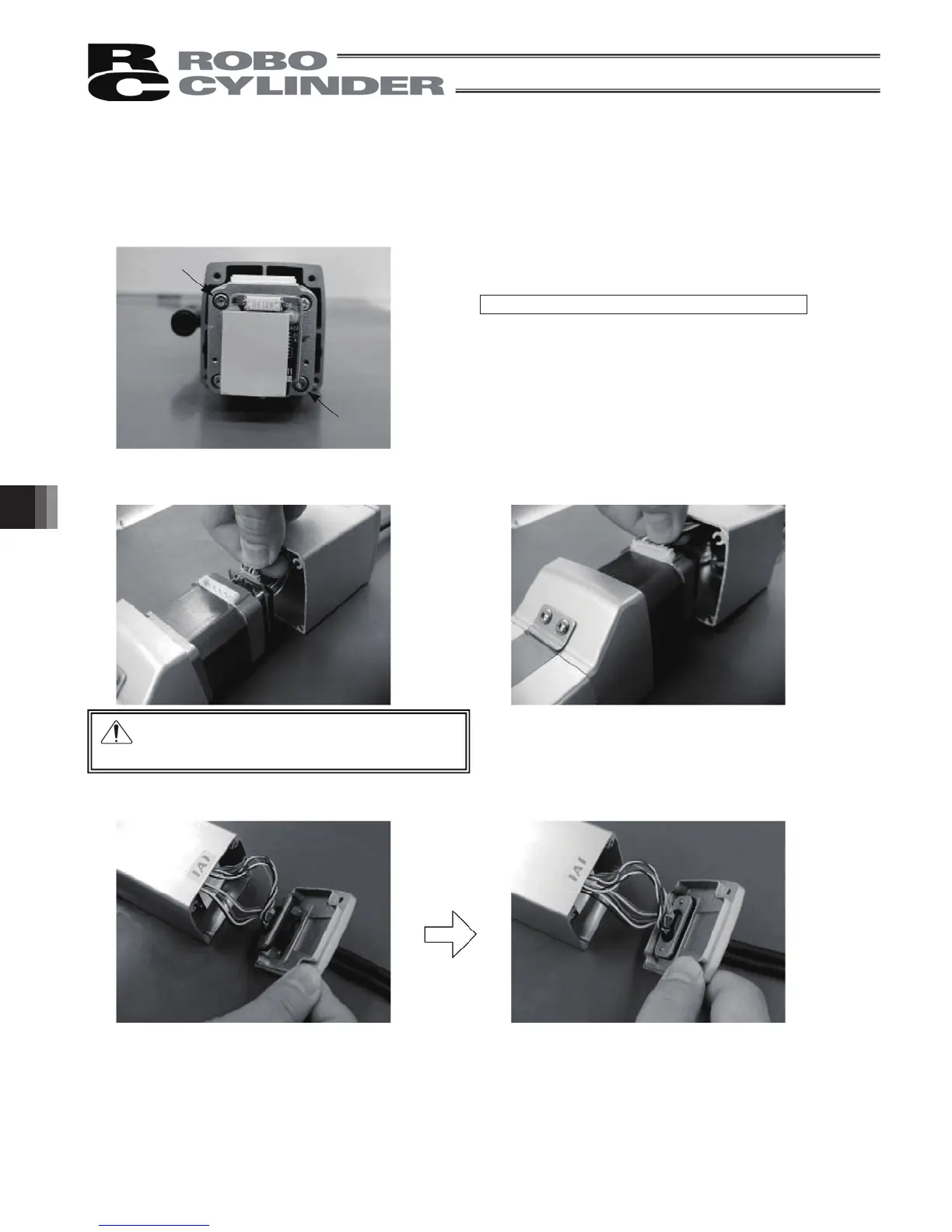

• After confirming that the angles of projections and depressions on the couplings are aligned, tighten the

affixing bolts (M3 × 50, 2 pcs.).

(Use an Allen wrench of 2.5 mm across flats.)

Tightening torque: 59 N·cm (6 kgf·cm)

8) Connect the encoder connector. 9) Connect the motor connector.

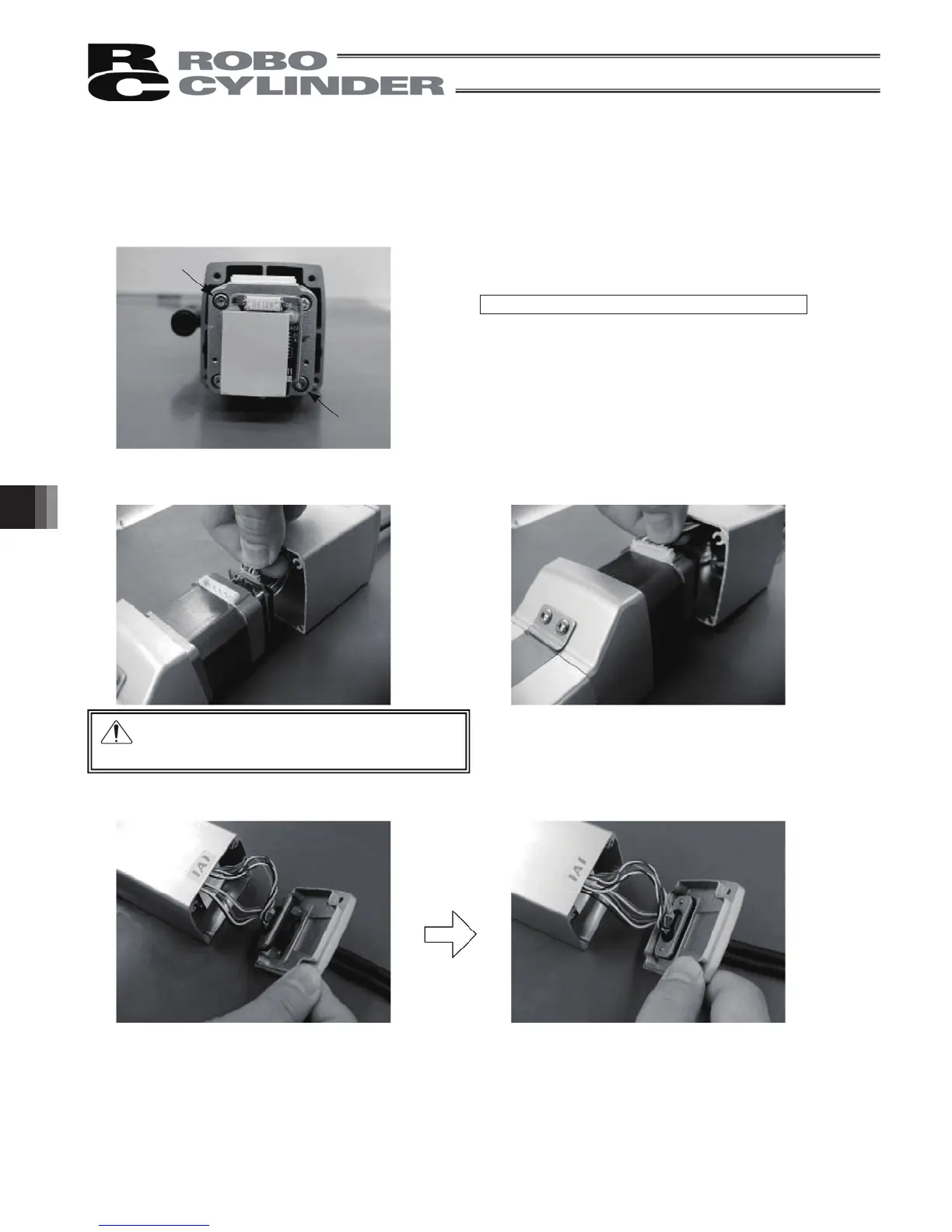

10) Replace the cable-end molding in the original position, and affix it

with the flat countersunk-head screws (M3 × 8, 2 pcs.).

Caution: Do not apply a force to the encoder

by touching it directly

Loading...

Loading...