sion

to

the

current

level

wi

II

be

required.

Time

and

parts for this conversion may

be

charged

to Code

32.

B/M 1280498

includes

the

following parts:

Ref.

Part

No.

Description

1

1164310

Pu

lIey,

Ti

It

2

1128455

Stud,

Ti

It

Pu

lIey{redesigned}

3 1164099

Washer,

Fe

It

4 1164158

Washer,

Spacer

When orderi

ng

the

above

bi

II

of

materi a I,

it

wi

II

be

necessary

to

order

a new ti

It

tape

to be used in

con-

junction

with

the

above

bi II. The new ti

It

tape

part

numbers

are

as follows:

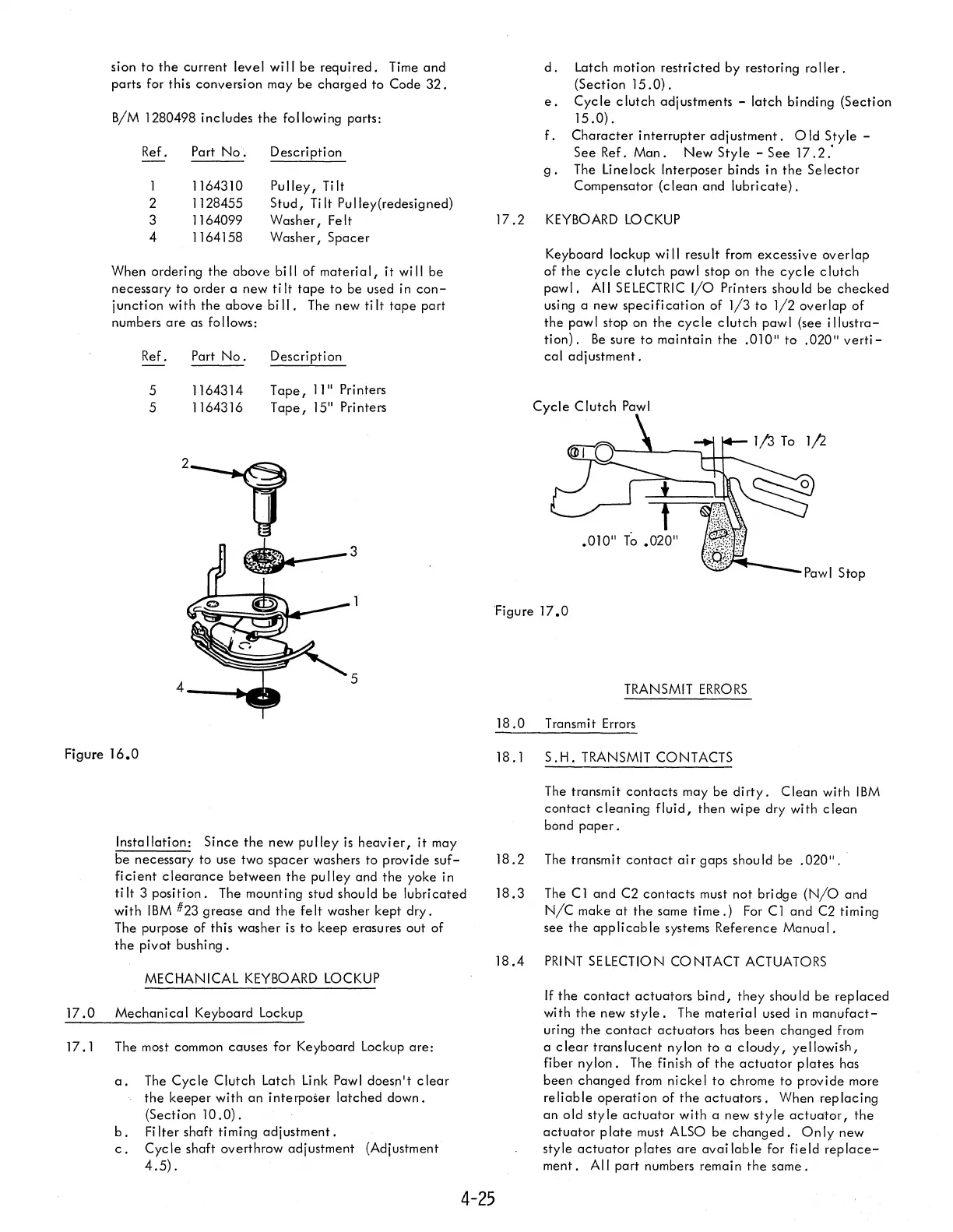

Figure

16.0

Ref.

5

5

Part

No.

1164314

1164316

4

__

....

l1li

Description

Tape,

11" Printers

Tape,

15" Printers

5

Installation:

Since

the

new

pulley

is

heavier,

it

may

be necessary to use two

spacer

washers to provide

suf-

ficient

clearance

between

the

pulley

and

the

yoke in

tilt

3

position.

The mounting stud should be

lubricated

with

IBM

#23

grease

and

the

felt

washer

kept

dry.

The purpose of this

washer

is

to

keep

erasures

out

of

the

pivot

bushing.

MECHANICAL

KEYBOARD

LOCKUP

17.0

Mechanical

Keyboard Lockup

17.1 The most common causes for Keyboard Lockup

are:

a.

The

Cycle

Clutch

Latch Link Pawl

doesn't

clear

the

keeper

with

an

interposer

latched

down.

(Section

1O.0).

b.

Fi

Iter shaft timing

adjustment.

c.

Cyc

Ie

shaft overthrow adjustment (Adjustment

4.5).

17.2

d.

Latch motion

restricted

by restori

ng

ro

lIer .

{Section

15.0}.

e.

Cycle

clutch

adjustments -

latch

binding (Section

15.0).

f.

Character

interrupter

adjustment.

Old

Style

-

See

Ref.

Man.

New

Style

-

See

17.2:

g.

The Linelock Interposer binds in

the

Selector

Compensator {clean

and

lubricate}.

KEYBOARD

LOCKUP

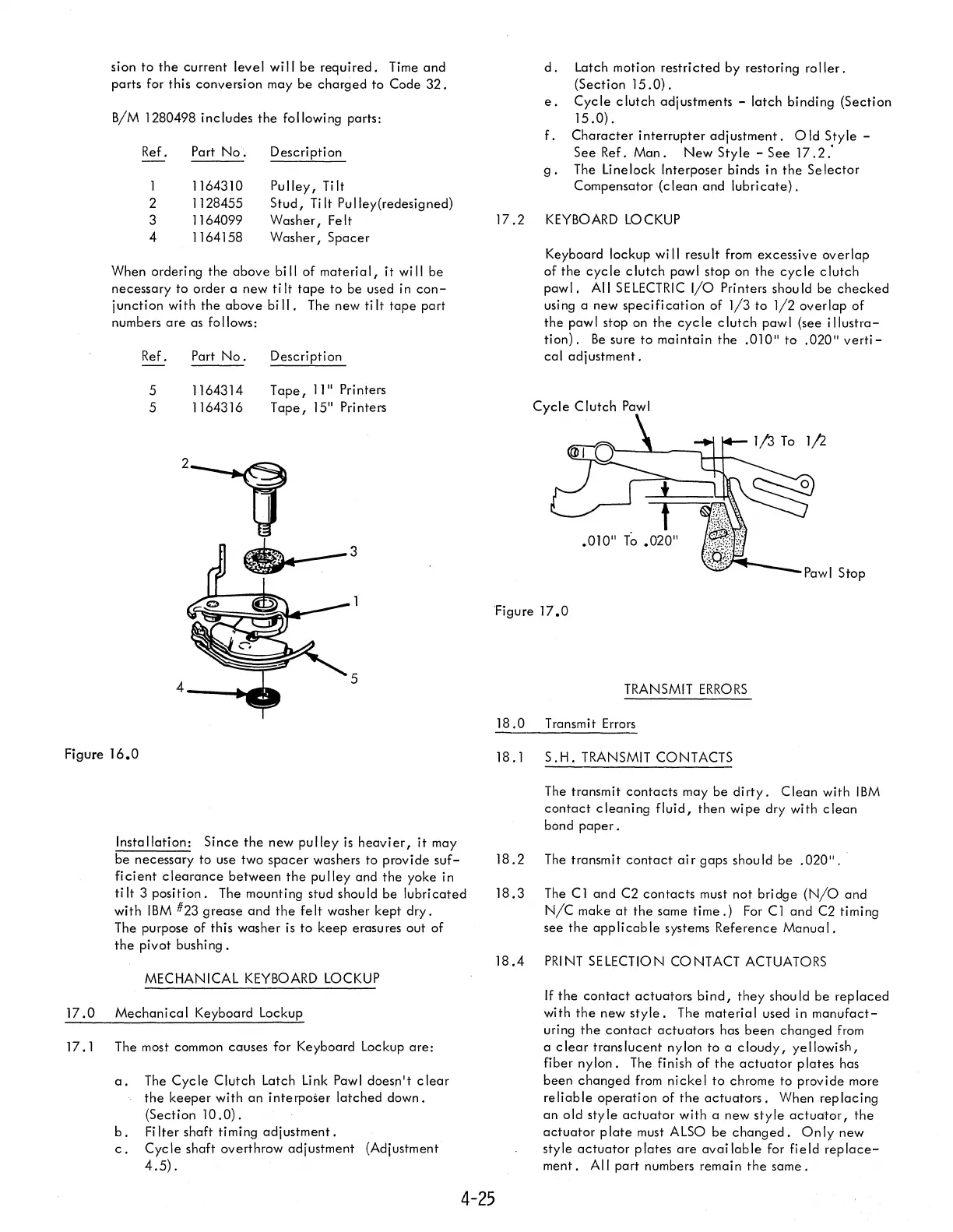

Keyboard lockup

wi

II

resu

It

from

excessive

overlap

of

the

cycle

clutch

pawl stop on

the

cycle

clutch

pawl.

All

SELECTRIC

I/O

Printers should be

checked

using a new

specification

of

1/3

to

1/2

overlap

of

the

pawl stop on

the

cycle

clutch

pawl {see

illustra-

tion}.

Be

sure

to

maintain

the

.010"

to

.020"

verti-

cal

adjustment.

Cycle

Clutch

Pawl

.010"

To

.020"

Pawl Stop

-Figure

17.0

TRANSMIT

ERRORS

18.0

Transmit Errors

18.1

S.H.

TRANSMIT CONTACTS

The transmit

contacts

may be

dirty.

Clean

with

IBM

contact

cleaning

fluid,

then

wipe

dry with

clean

bond

paper.

18.2

The transmit

contact

air

gaps should

be

.020".

-

18.3

The C 1

and

C2

contacts

must

not

bri dge

{N/O

and

N/C

make

at

the

same

time.}

For

Cl

and

C2 timing

see

the

applicable

systems

Reference

Manual.

18.4

PRINT

SELECTION CONTACT ACTUATORS

If

the

contact

actuators

bind,

they

should be

replaced

with

the

new

style.

The

material

used in

manufact-

uring

the

contact

actuators

has

been

changed

from

a

clear

translucent

nylon to a

cloudy,

yellowish,

fiber

nylon.

The finish

of

the

actuator

plates

has

been

changed

from

nickel

to

chrome to provide more

reliable

operation

of

the

actuators.

When

replacing

an

old

style

actuator

with

a new

style

actuator,

the

actuator

plate

must ALSO

be

changed.

Only' new

style

actuator

plates

are

available

for

field

replace-

ment.

All

part

numbers remain

the

same.

4-25

Loading...

Loading...