Section

2.

Adjustments

ADJUSTMENT

THEORY

This

adjustment

is

extremely important because

the

rollers

on the latch bai I

MUST

contact

their

respective

selector

MOTOR AND

DRIVE

cams

at

the

same point and with

the

same pressure in

ord.

er

to insure

tha"t

both cams

operate

the

bail

together.

1.

Drive Belt - Adjust

the

motor mounting brackets forward

or

back

to obtain a minimum amount

of

belt

noise.

Both

ends of the motor must be adjusted

the

same in order

to

maintain

the

rotor shaft

perpendicular

to

the

drive belt.

The

belt

must never be so loose

that

jumping cogs

on

the

motor pulley

is

a possibility.

Check

by operating

the

shift mechanism while holding

the

carrier

with

the

car-

rier return

in

operation.

This

loads

the

motor

to

a point

where failure

will be most

probable.

2.

Motor Pulley - Adjust the motor

pulley

left or right so

that

the

drive

belt

rides fully on

the

teeth

of

both

pul-

leys without rubbing

the

flange of

either.

Position

the

retaining

clip

for

.005"

to

.015"

end

play.

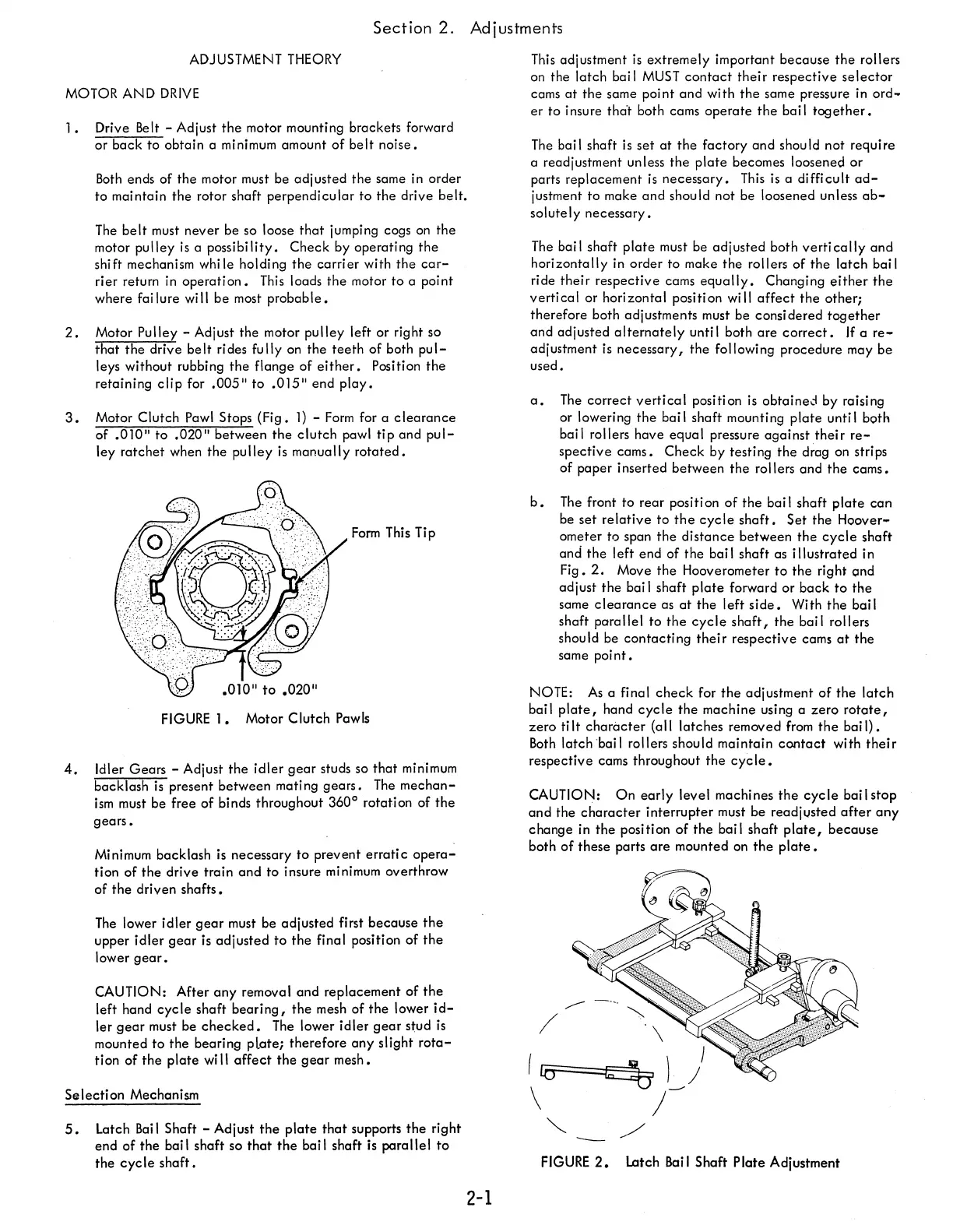

3.

Motor Clutch Pawl Stops

(Fig.

1)

-

Form

for a

clearance

of

.010"

to

.020"

between

the

clutch

pawl

tip

and

pul-

ley

ratchet

when

the

pulley

is

manually

rotated.

Form

This Tip

FIGURE

1.

Motor

Clutch

Pawls

4.

Idler Gears - Adjust

the

idler

gear

studs so

that

minimum

backlash

is

present between mating

gears.

The

mechan-

ism

must be free

of

binds throughout 360

0

rotation of

the

gears.

Minimum backlash

is

necessary to prevent

erratic

opera-

tion

of

the

drive train

and

to insure minimum overthrow

of

the

driven

shafts.

The

lower

idler

gear

must be adjusted first because

the

upper

idler

gear

is

adjusted

to

the

final position

of

the

lower

gear.

CAUTION: After

any

removal and replacement

of

the

left hand

cycle

shaft

bearing,

the

mesh of

the

lower

id-

ler

gear

must be

checked.

The lower idler

gear

stud

is

mounted

to

the

bearing

plate;

therefore

any

slight

rota-

tion of

the

plate

wi

11

affect

the

gear

mesh.

Selection

Mechanism

5.

latch

Bail Shaft - Adjust

the

plate

that

supports

the

right

end

of

the

bail shaft so

that

the

bail shaft is

parallel

to

the

cycle

shaft.

2-1

The

bail shaft

is

set

at

the

factory and should not require

a readjustment

un

less

the

plate

becomes loosened

or

parts replacement

is

necessary.

This

is

a

difficult

ad-

justment to make

and

should not be loosened unless

ab-

solutely necessary.

The bail shaft

plate

must be adjusted both

vertically

and

horizonta lIy in order to make

the

rollers

of

the

latch

bai I

ride

their

respective cams

equally.

Changing

either

the

vertical

or horizontal position will

affect

the

other;

therefore both adjustments must be considered

together

and adjusted

alternately

until both

are

correct.

If

a

re-

adjustment

is

necessary,

the

following procedure may

be

used.

a.

The

correct

vertical

position

is

obtained

by raising

or lowering

the

bail shaft mounting

plate

until both

bail

rollers have

equal

pressure

against

their

re-

spective

cams.

Check

by testing

the

drag on strips

of

paper inserted between

the

rollers and

the

cams.

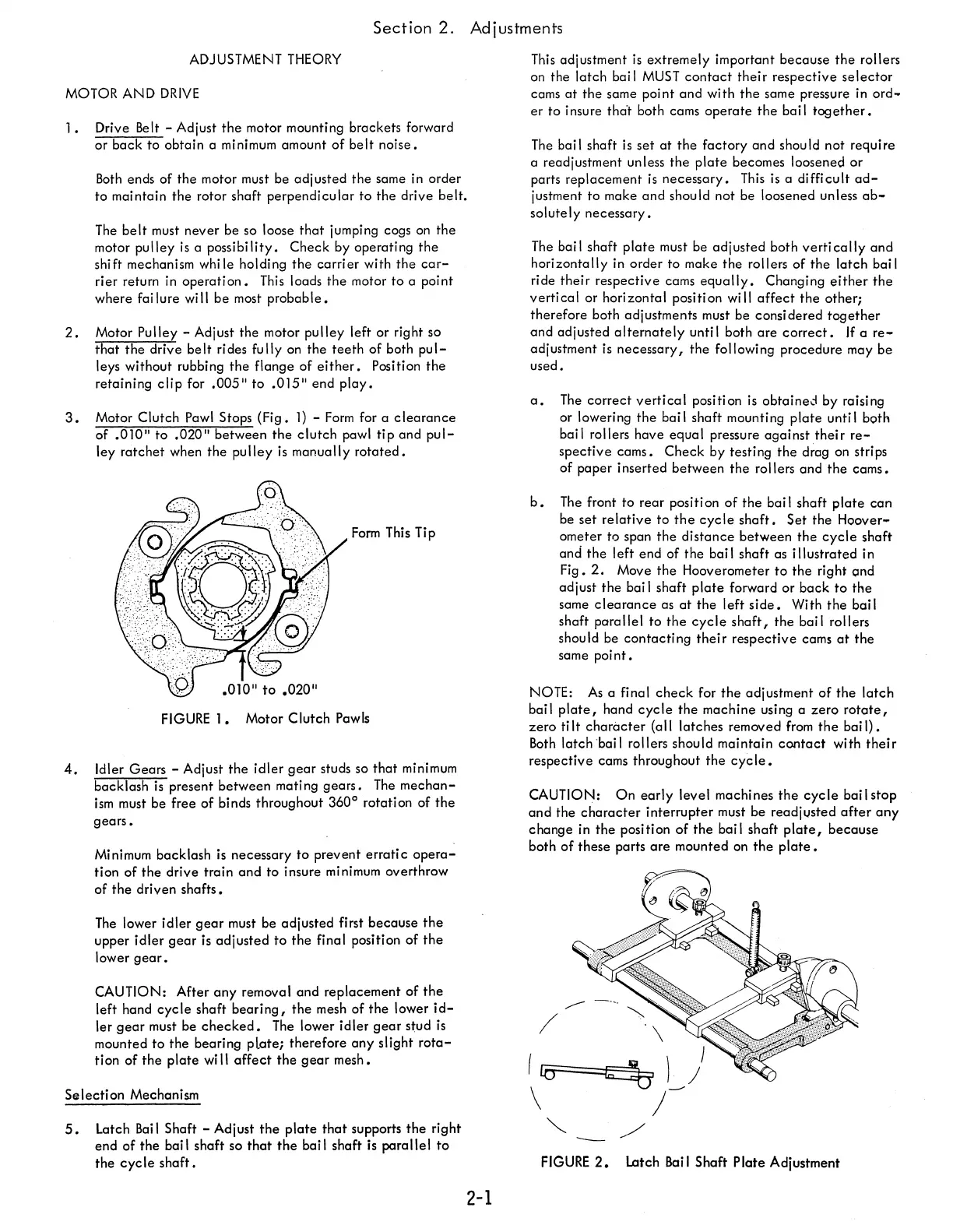

b.

The

front to rear positi on

of

the

bail shaft

plate

can

be

set

relative

to

the

cycle

shaft.

Set

the

Hoover-

ometer to span

the

distance

between

the

cycle

shaft

and

the

left end

of

the

bail shaft as

illustrated

in

Fig.

2.

Move

the

Hooverometer

to

the

right

(;md

adjust

the

bai I shaft

plate

forward or

back

to

the

same

clearance

as

at

the

left

side.

With

the

bai I

shaft

parallel

to

the

cycle

shaft,

the

bai I rollers

should be

contacting

their

respective cams

at

the

same

point.

NOTE:

As

a final

check

for

the

adjustment

of

the

latch

bail

plate,

hand

cycle

the

machine using a

zero

rotate,

zero

ti

It

character

(a

II

latches

removed

from

the

bai

I)

•

Both

latch 'bai I rollers should maintain

contact

with

their

respective cams throughout

the

cyc

Ie.

CAUTION:

On

early

level machines

the

cycle

bai I stop

and

the

character

interrupter

must be readjusted

after

any

change in

the

position

of

the

bail shaft

plate,

because

both

of

these parts

are

mounted on

the

plate.

,--

"'"

/

\

leo

q

t_J

J

\

)

"---

.-/

FIGURE

2.

Latch

Bai

I Shaft

Plate

Adjustment

Loading...

Loading...