11. Tab Interlock

Contact-

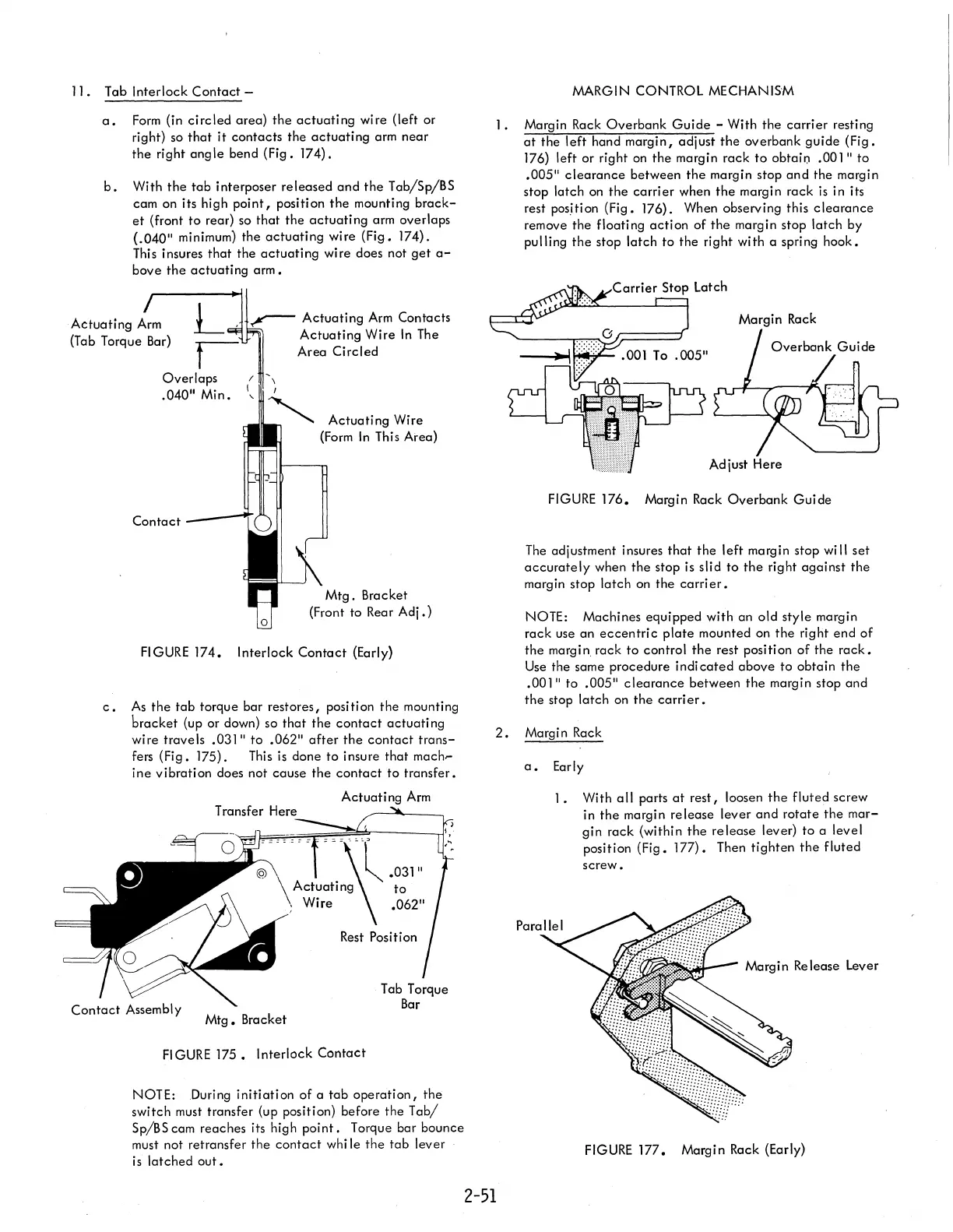

a.

Form

(in

circled

area)

the

actuating

wire (left or

right) so

that

it

contacts

the

actuating

arm

near

the

right

angle

bend

(Fig.

174).

b.

With

the tab

interposer

released

and

the

Tab/Sp/BS

cam on its high

point,

position

the

mounting

brack-

et

(front

to

rear) so

that

the

actuating

arm overlaps

(.040" minimum) the

actuating

wire

(Fig.

174).

This insures

that

the

actuating

wire does not

get

a-

bove

the

actuating

arm.

Actuating

Arm

(Tab Torque Bar)

Overlaps

.040"

Min.

Contact

Actuating

Arm

Contacts

Actuating

Wire

In

The

Area

Circled

Actuating

Wire

(Form

In

This Area)

Mtg.

Bracket

(Front to Rear

Adj.)

FIGURE

174.

Interlock

Contact

(Early)

c.

As

the tab

torque bar restores, position

the

mounting

bracket

(up or down) so

that

the

contact

actuating

wire travels .031"

to

.062"

after

the

contact

trans-

fers

(Fig.

175). This

is

done

to

insure

that

mach-

ine

vibration

does not

cause

the

contact

to

transfer.

Actuating

Arm

==~'OOl.031"

Actuating

to

Wire

.062"

Rest

Position

Mtg.

Bracket

FIGURE

175.

Interlock

Contact

NOTE: During

initiation

of

a

tab

operation,

the

switch must transfer (up position) before the

Tab/

Sp/BS cam reaches its high

point.

Torque bar bounce

must not retransfer

the

contact

whi

Ie

the tab

lever

is

latched

out.

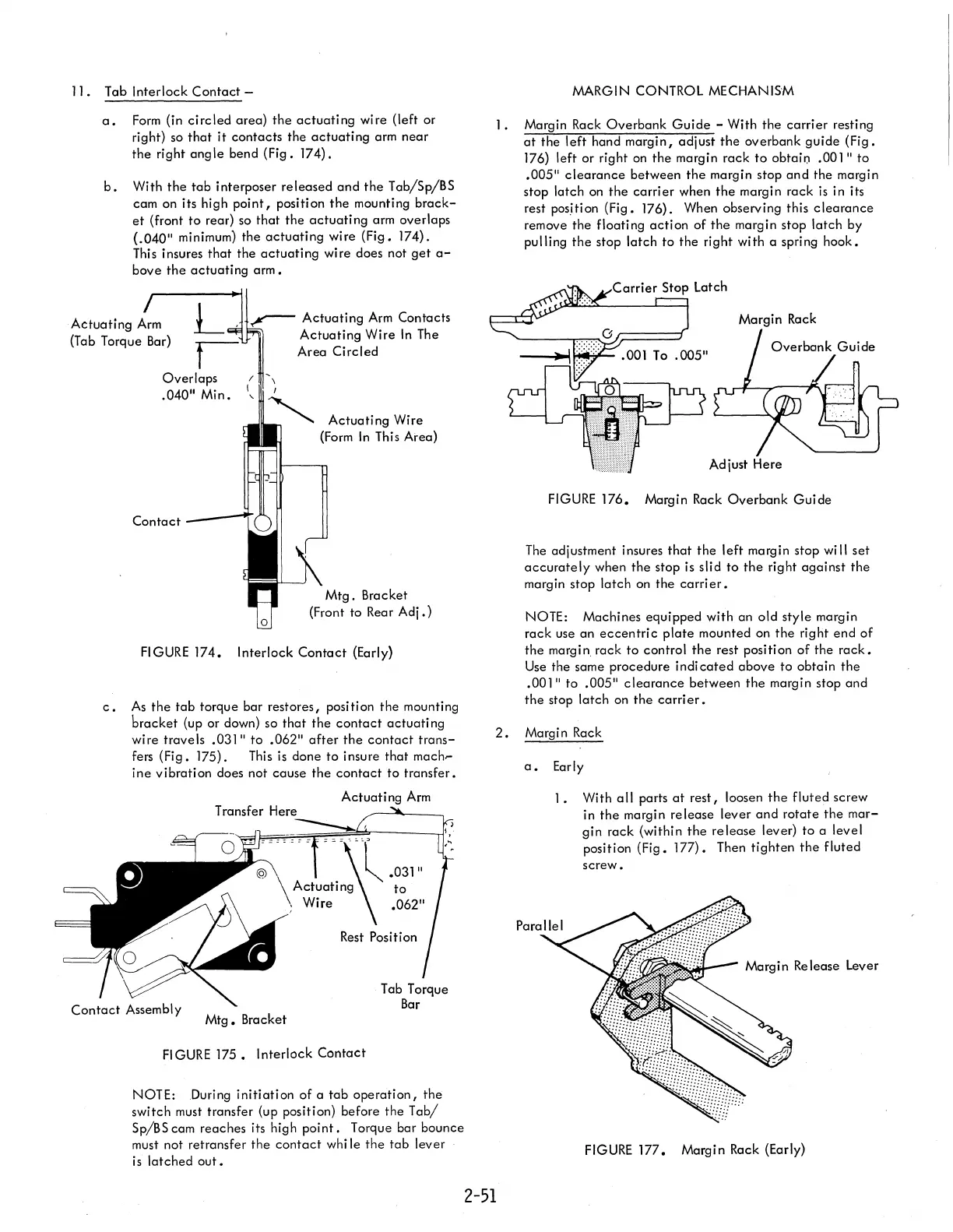

MARGIN CONTROL MECHANISM

1.

Margin Rack

Overbank

Guide

- With

the

carrier

resting

at

the

left

hand

margin,

adjust

the

overbank

guide

(Fig.

176)

left or right on

the

margin

rack

to

obtai!) .00

I"

to

.005"

clearance

between

the

margin stop

and

the margin

stop

latch on

the

carrier

when

the

margin rack is in its

rest pos.ition (Fig.

176). When observing this

clearance

remove the floating

action

of

the

margin stop

latch

by

pulling

the

stop

latch

to the right with a spring

hook.

FIGURE

176.

Margin Rack

Overbank

Guide

The

adjustment insures

that

the

left

margin stop will

set

accurately

when

the

stop is slid

to

the

right

against

the

margin stop latch on the

carrier.

NOTE: Machines equipped with an old style margin

rack

use an

eccentric

plate

mounted on

the

right

end

of

the

margin. rack

to

control

the

rest position

of

the

rack.

Use

the same procedure

indicated

above

to

obtain

the

.001"

to

.005"

clearance

between

the

margin stop and

the

stop latch on

the

carri

er.

2.

Margin Rack

2-51

a.

Early

1.

With

all

parts

at

rest,

loosen

the

fluted screw

in

the

margin

release

lever

and

rotate

the

mar-

gin

rack (within

the

release

lever) to a level

position

(Fig.

177).

Then

tighten

the

fluted

screw.

FIGURE

177.

Margin Rack (Early)

Loading...

Loading...