(b) Degree Wheel Method - With

the

machine

at

zero

degrees (cycle

clutch

latched

at

rest)

se-

lect

a

-5

rotate,

0

tilt

character

and

hand

cy-

cle

the machine slowly. The

cycle

clutch

spring should slip and stop driving

at

170 to

175

degrees.

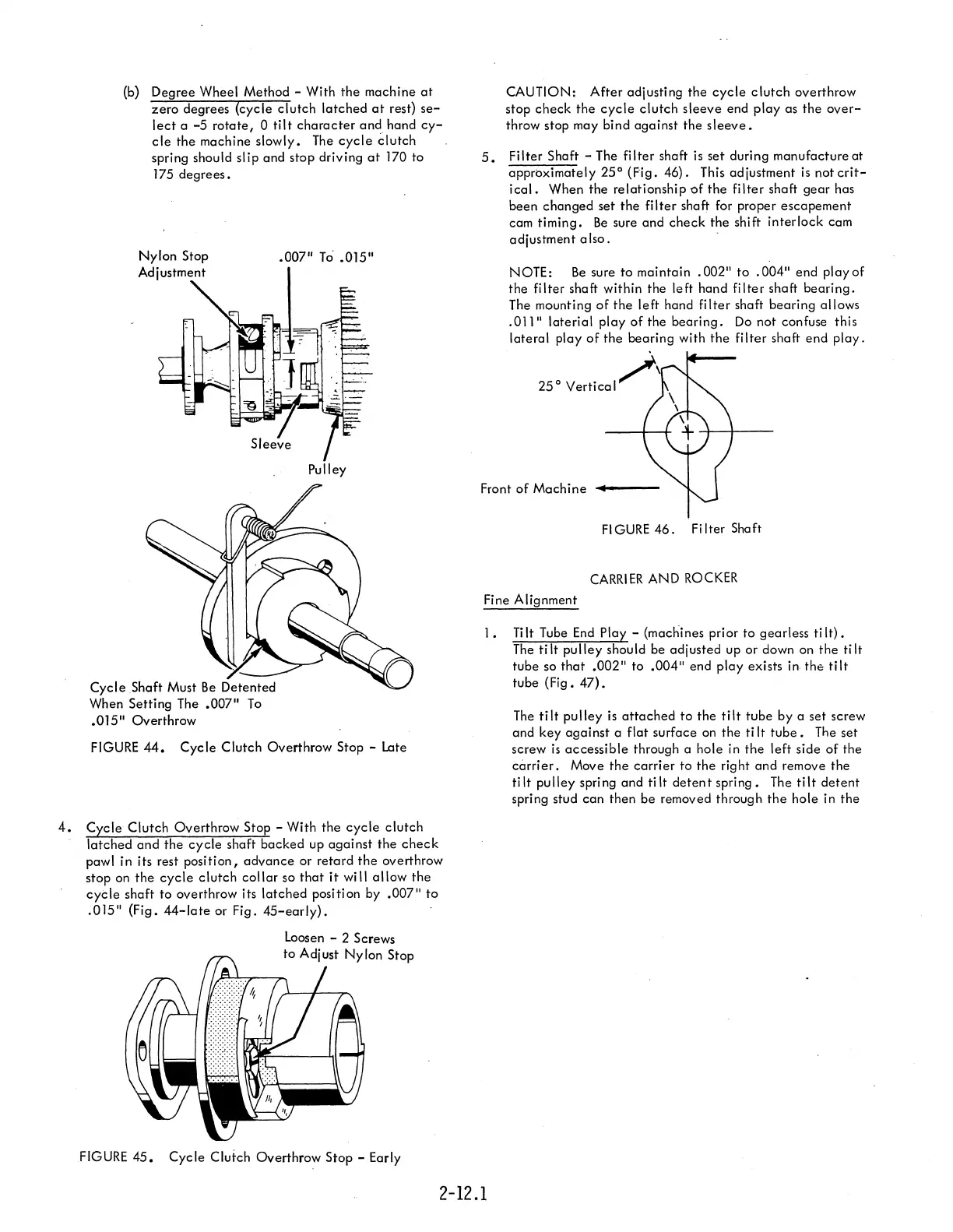

Nylon

Stop

Adjustment

Cycle

Shaft

Must

Be

Detented

When Setting The

.007"

To

.015"

Overthrow

.007"

To'

.015"

Pulley

FIGURE

44.

Cycle

Clutch Overthrow Stop - Late

4.

Cycle

Clutch

Overthrow Stop - With

the

cycle

clutch

latched

and

the

cycle

shaft

backed

up

against

the

check

pawl in its rest

position,

advance

or retard

the

overthrow

stop on

the

cycle

clutch

collar

so

that

it

will

allow

the

cycle

shaft

to overthrow its

latched

position by

.007"

to

;015"

(Fig.

44-late

or Fig.

45-early).

FIGURE

45.

Cycle

Clutch Overthrow Stop - Early

CAUTION:

After

adjusting

the

cycle

clutch

overthrow

stop

check

the

cycle

clutch

sleeve

end

playas

the

over-

throw stop may bind

against

the

sleeve.

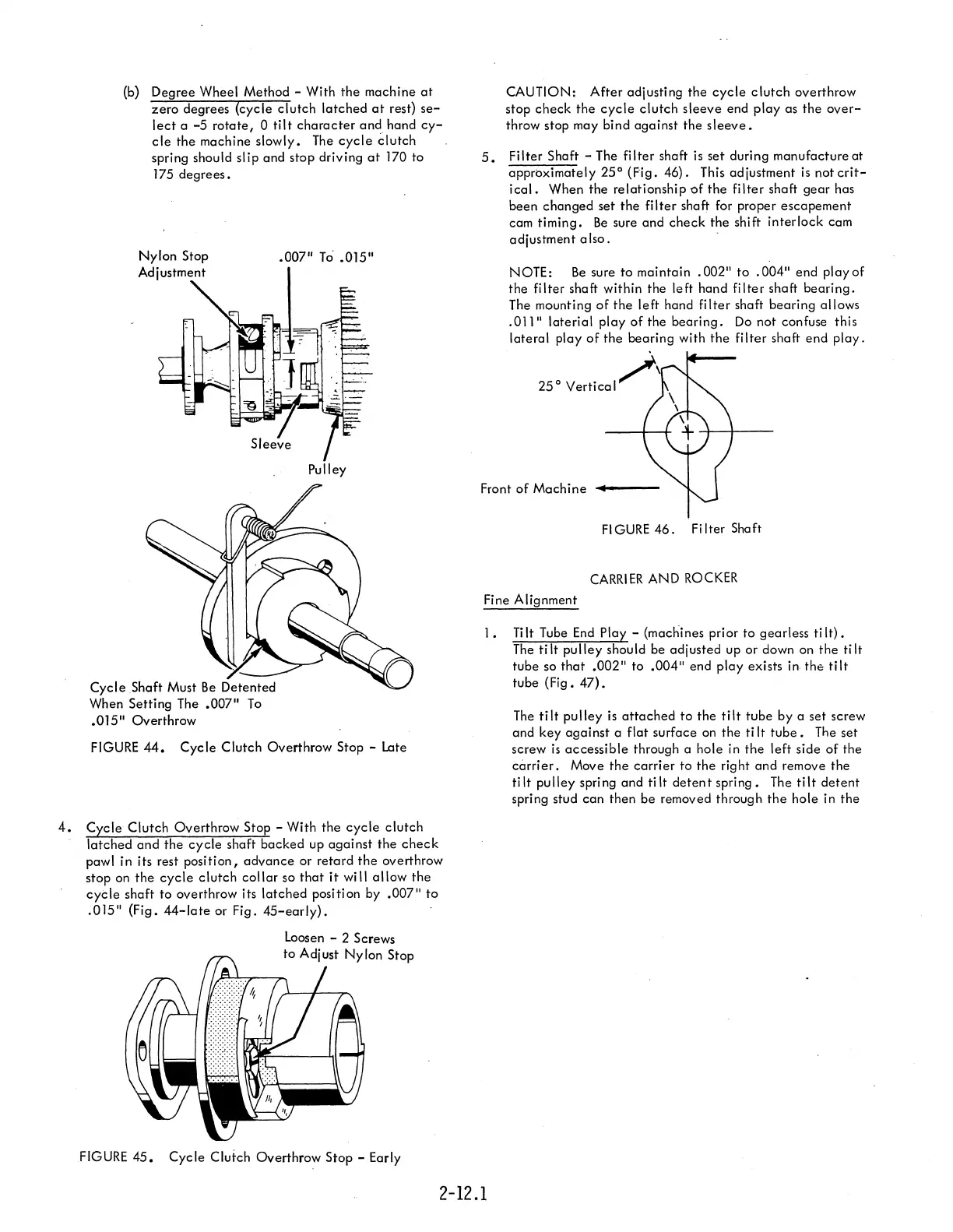

5.

Fi

Iter Shaft - The

filter

shaft is

set

during manufacture

at

approximately

25°

(Fig.

46).

This adjustment

is

not

crit-

ical.

When the relationship

~f

the

filter

shaft

gear

has

been

changed

set

the

filter

shaft for proper

escapement

cam

timing.

Be

sure and

check

the shift

interlock

cam

adjustment a

Iso.

NOTE:

Be

sure to maintain

.002"

to

.004"

end

playof

the filter shaft within the left hand

filter

shaft

bearing.

The mounting

of

the

left

hand

filter

shaft

bearing

allows

.011"

laterial

play

of

the

bearing.

Do

not confuse this

lateral

play

of

the

bearing with

the

filter

shaft

end

play.

25°

Vertical/\

Front

of

Machine

....

_--

FIGURE

46.

Filter Shaft

CARRIER

AND

ROCKER

Fine Alignment

1.

Ti

It

Tube

End

Play - (machines prior

to

gearless ti

It).

The

tilt

pulley

should be adjusted up or down on

the

tilt

tube so

that

.002"

to

.004"

end

play

exists in

the

tilt

tube (Fig.

47).

The

tilt

pulley

is

attached

to

the

tilt

tube

by a set screw

and key

against

a flat surface on the ti

It

tube.

The set

screw

is

accessible

through a hole in

the

left side

of

the

carrier.

Move

the

carrier

to

the

right

and

remove the

tilt

pulley

spring and

tilt

detent

spring.

The

tilt

detent

spring stud

can

then

be

removed through

the

hole in

the

2-12.1

Loading...

Loading...