The .025"

to

.035" skirt

clearance

allows

the

rotate

de-

tent

to

enter

and withdraw

from

the

type head notch

area

at

the

proper time with respect to

the

rotating

typehead.

If

this

clearance

is

too small

the

rotate

detent

will

enter

the

notch

area

too

early

and

withdraw too

late.

This

will also cause an intermittent erroneous

character

to

print,

parts

breakage,

or unwanted roller

droppage.

Too

much skirt

clearance

will

only

cause premature wear on

the

detent

mechanism due to

the

leverage

gain.

Since

the

detent

cam

and

print cam

are

both keyed

to

the

print

shaft,

the

relationship between

the

detent

tim-

ing

and

the point

at

whi ch

the

typehead

prints

is

non-

adjustable.

The design

of

the

two cams

is

such

that

the

detents will be fully

seated

in

their

notches when

the

typehead

contacts

the

platen

durin~

a print

operation.

The

only

thing

that

can

affect

this timing relationship

is

the

position

of

the

detent

cam follower mounting

brack-

et.

The position

of

this

bracket

is

fixed

at

the factory

and shou

Id

not be

changed.

II.

Detent Mechanism (Gearless

Ti

It)

The

detent

mechanism must be adjusted

to

satisfy

the

following conditions:

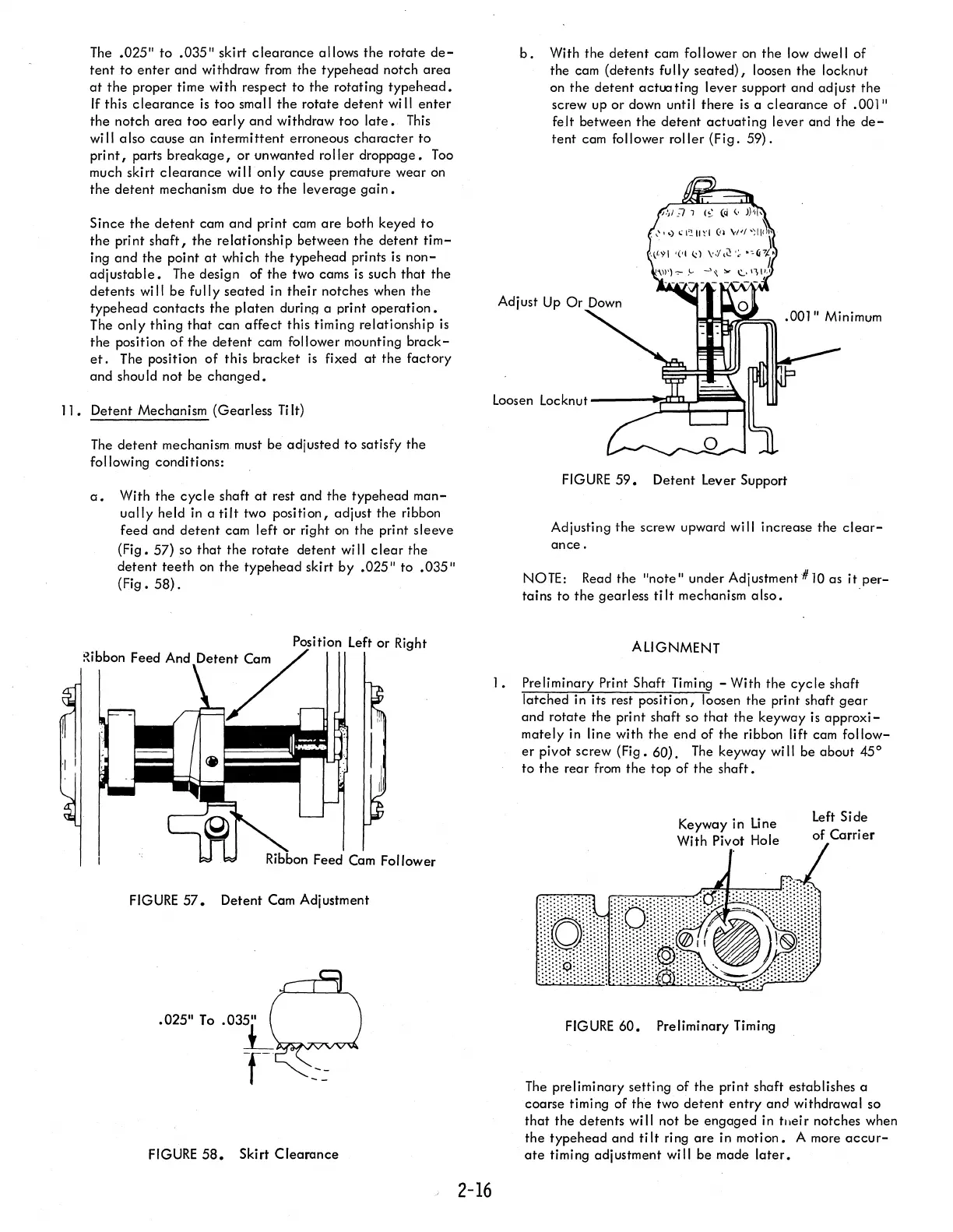

a.

With

the

cycle

shaft

at

rest and

the

typehead

man-

ually

held in a

tilt

two position, adjust the ribbon

feed and

detent

cam left

or

right

on

the print

sleeve

(Fig.

57)

so

that

the

rotate

detent

wi

II c

lear

the

detent

teeth

on

the

type head skirt

by

.025" to .035"

(Fig.

58).

Feed Cam Follower

FIGURE

57. Detent Cam Adjustment

.025"

To

FIGURE

58.

Skirt

Clearance

2-16

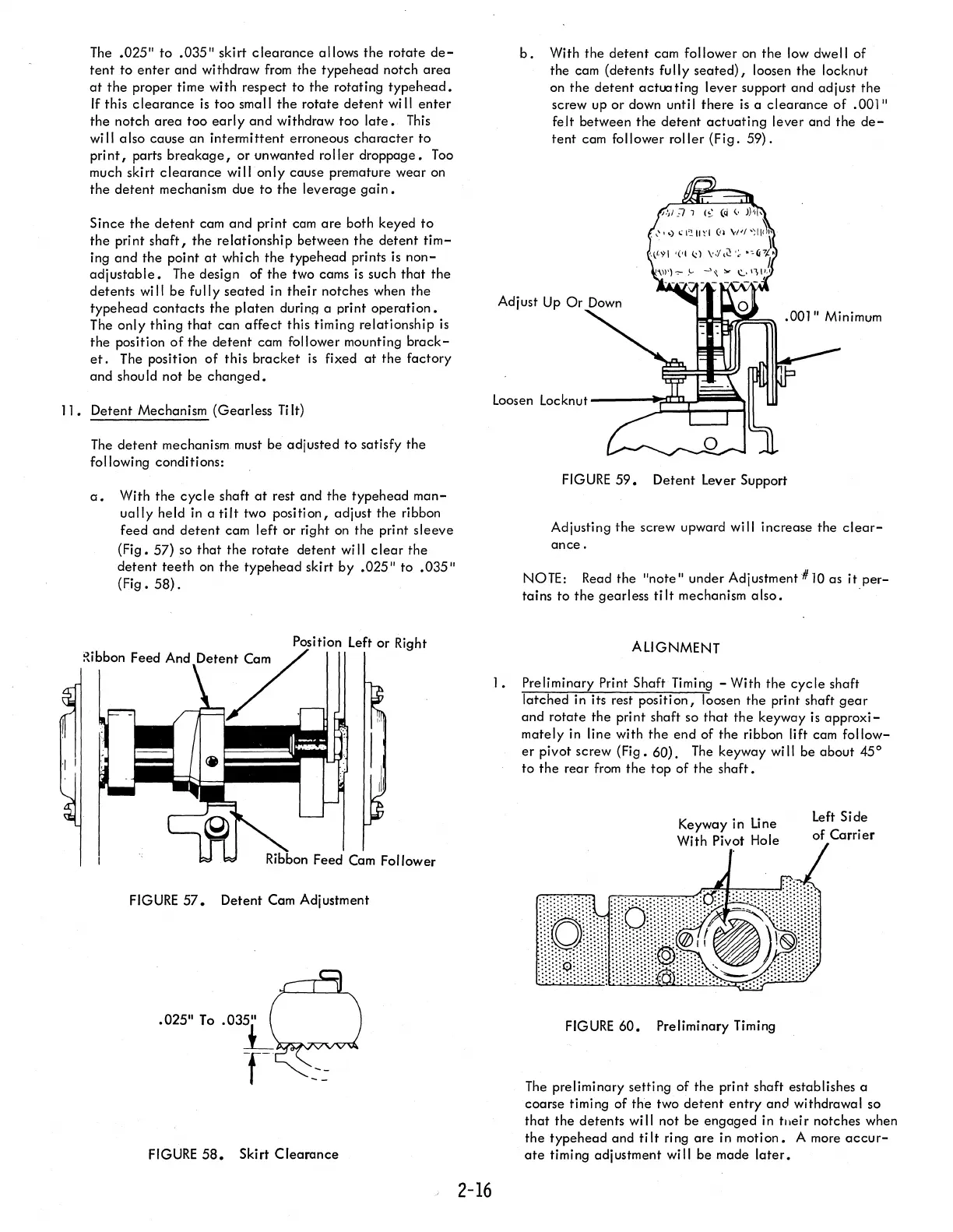

b.

With

the

detent

cam follower

on

the

low dwell of

the cam (detents fully

seated),

loosen the locknut

on

the

detent

actua ting

lever

support and adjust

the

screw up

or

down unti I

there

is

a

clearance

of

.001"

felt between

the

detent

actuating

lever and the

de-

tent

cam follower roller

(Fig.

59).

.001" Minimum

Loosen Locknut

----:~~~=::::~I

FIGURE

59.

Detent

Lever Support

Adjusting

the

screw upward will increase

the

clear-

ance.

NOTE: Read the

"note"

under Adjustment #10 as

it

per-

tains to

the

gearless ti It mechanism a Iso.

ALIGNMENT

I.

Preliminary Print Shaft Timing - With

the

cycle

shaft

latched in its rest position, loosen

the

print shaft

gear

and rotate

the

print shaft so

that

the

keyway

is

approxi-

mately in line with

the

end of

the

ribbon lift cam

follow-

er

pivot screw (Fig. 60).

The

keyway

wi

II

be about 45°

to

the

rear

from

the

top

of

the

shaft.

FIGURE

60. Preliminary Timing

Left Side

of

Carrier

The preliminary setting of

the

print shaft establishes a

coarse timing

of

the

two

detent

entry

and

withdrawal so

that

the

detents will not be

engaged

in tlleir notches when

the

typehead

and

tilt

ring

are

in motion. A more

accur-

ate

timing adjustment

wi

II be made

later.

Loading...

Loading...