6.

Differential

Guides

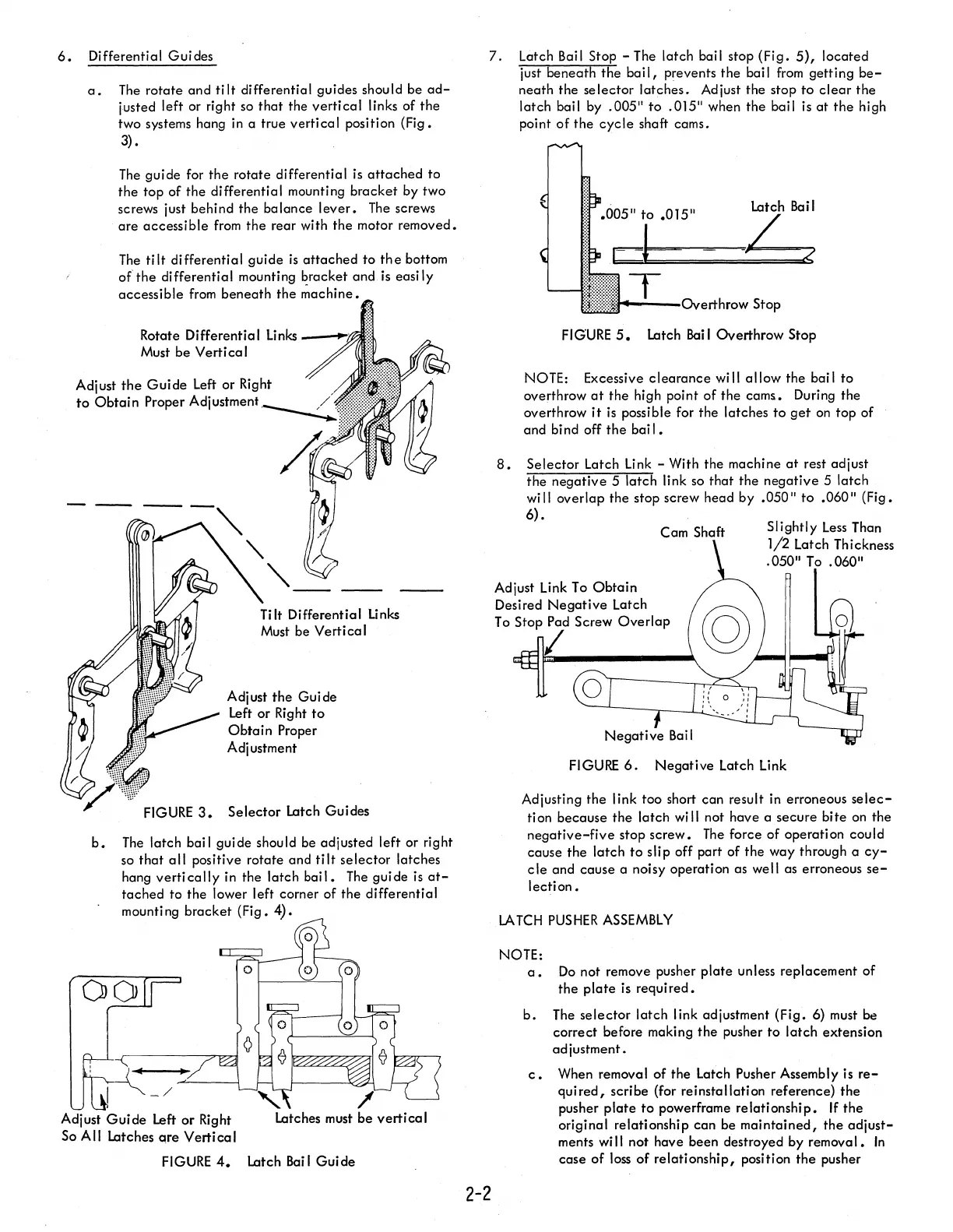

a.

The

rotate

and

tilt

differential guides should be

ad-

justed left or right so

that

the

vertical

links of

the

two systems hang in a true

vertical

position (Fig.

3).

The

guide for

the

rotate differential

is

attached

to

the

top of the differential mounting

bracket

by two

screws just behind the balance

lever.

The

screws

are

accessible

from

the

rear with

the

motor removed.

The

tilt

differential guide

is

attached

to

the

bottom

of'the

differential mounting bracket and

is

easi

Iy

accessible

from

beneath

the

~achine.

Rotate Differential links

__

~!0'i

Must be

Vertical

Adjust

the

Guide

left

or Right

to

Obtain

Proper Adjustment

Tilt Differential Unks

Must be

Vertical

Adjust

the

Guide

left

or Right

to

Obtain

Proper

Adjustment

FIGURE

3.

Selector

Latch Guides

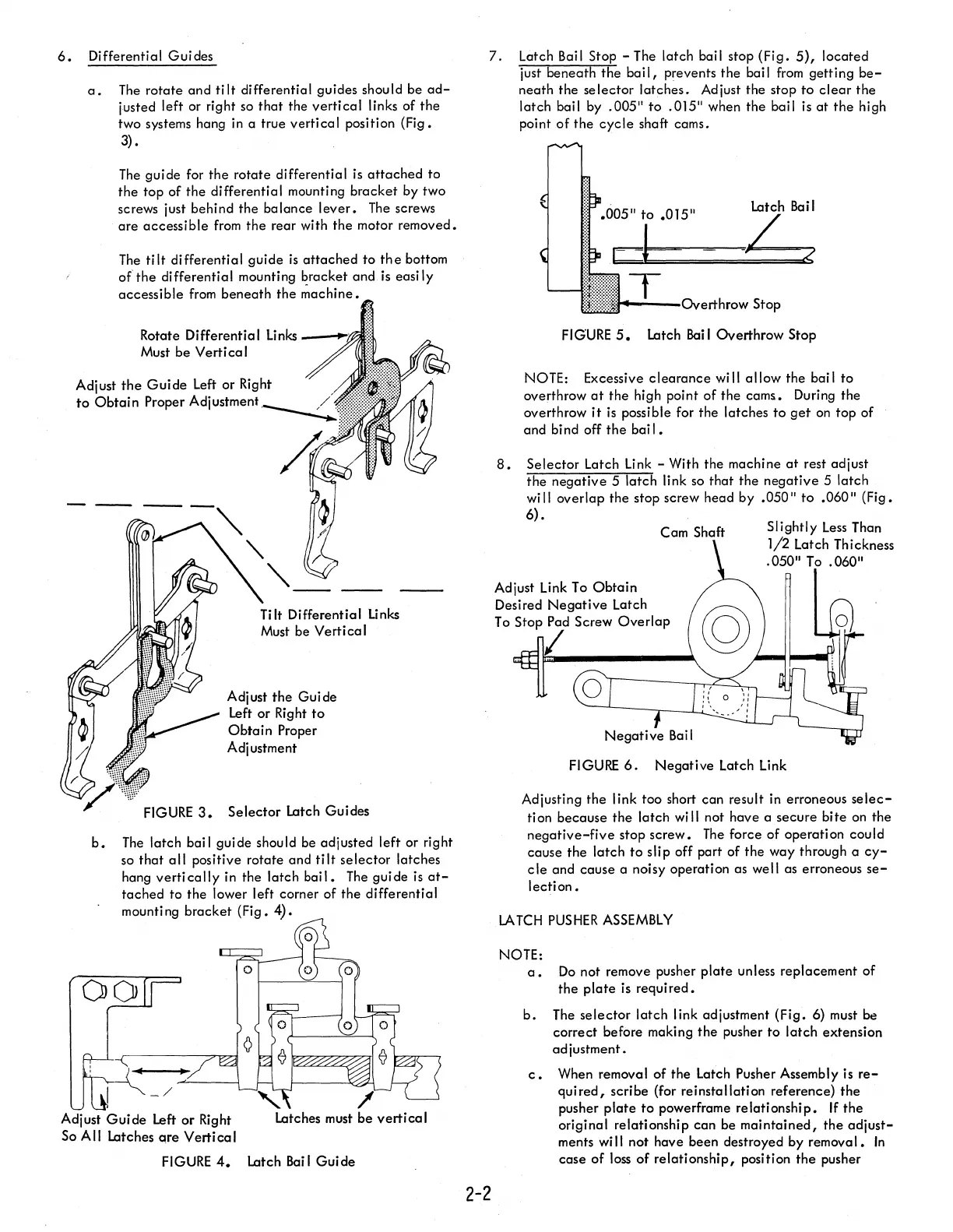

b.

The

latch bail guide should be adjusted left or right

so

that

all

positive rotate and

tilt

selector

latches

hang

vertically

in the

latch

bail.

The

guide

is

at-

tached

to the lower left corner of the differential

mounting

bracket

(Fig. 4).

Adjust

Guide

left

or

Right

latches

must

be

vertical

So All

latches

qre

Vertical

FIGURE

4.

latch

Bai

I

Guide

7.

latch

Bail Stop

-The

latch bail stop

(Fig.

5),

located

just beneath

the

bail,

prevents the bail

from

getting

be-

neath the

selector

latches.

Adjust the stop

to

clear

the

latch bail by .005"

to

.015" when

the

bail is

at

the

high

point

of

the

cycle

shaft cams.

2-2

latch

Bail

/

-~

?

:::::::~~'"-..,;-._.n..,

..

rI·hrr'w

Stop

FIGURE

5.

latch

Bail Overthrow Stop

NOTE: Excessive

clearance

will

allow

the bail

to

overthrow

at

the high point of

the

cams. During the

overthrow

it

is

possible for the latches

to

get

on

top

of

and

bi

nd

off

the

bai I •

8.

Selector

latch

link

- With the machine

at

rest adjust

the

negative

5 latch link so

that

the

negative

5 latch

wi

II

overlap the stop screw head by .050"

to

.060" (Fig.

6).

Adjust

link

To

Obtain

Desired

Negative

latch

Cam Shaft

To

Stop Pad Screw

Overlap

I

Slightly

less

Than

1/2

latch

Thickness

.050"

To

.060"

FIGURE

6.

Negative

latch

link

Adjusting

the

I ink too short can result in erroneous

selec-

tion because

the

latch will not have a secure

bite

on the

negative-five

stop

screw.

The

force of operation could

cause the

latch

to

slip off part of

the

way through a

cy-

cle

and cause a noisy operation as well as erroneous

se-

lection.

LA

TCH

PUSHER

ASSEMBLY

NOTE:

a.

Do

not remove pusher

plate

unless replacement of

the

plate

is

required.

b.

The

selector

latch link adjustment

(Fig.

6) must

be

correct before making

the

pusher

to

latch

extension

adjustment.

c.

When removal of

the

Latch Pusher Assembly is

re-

quired,

scribe (for reinstallation reference)

the

pusher

plate

to

powerframe

relationship.

If

the

original relationship can be

maintained,

the

adjust-

ments

wi

II

not have been destroyed by remova

I.

In

case

of

loss

of

relationship, position

the

pusher

Loading...

Loading...