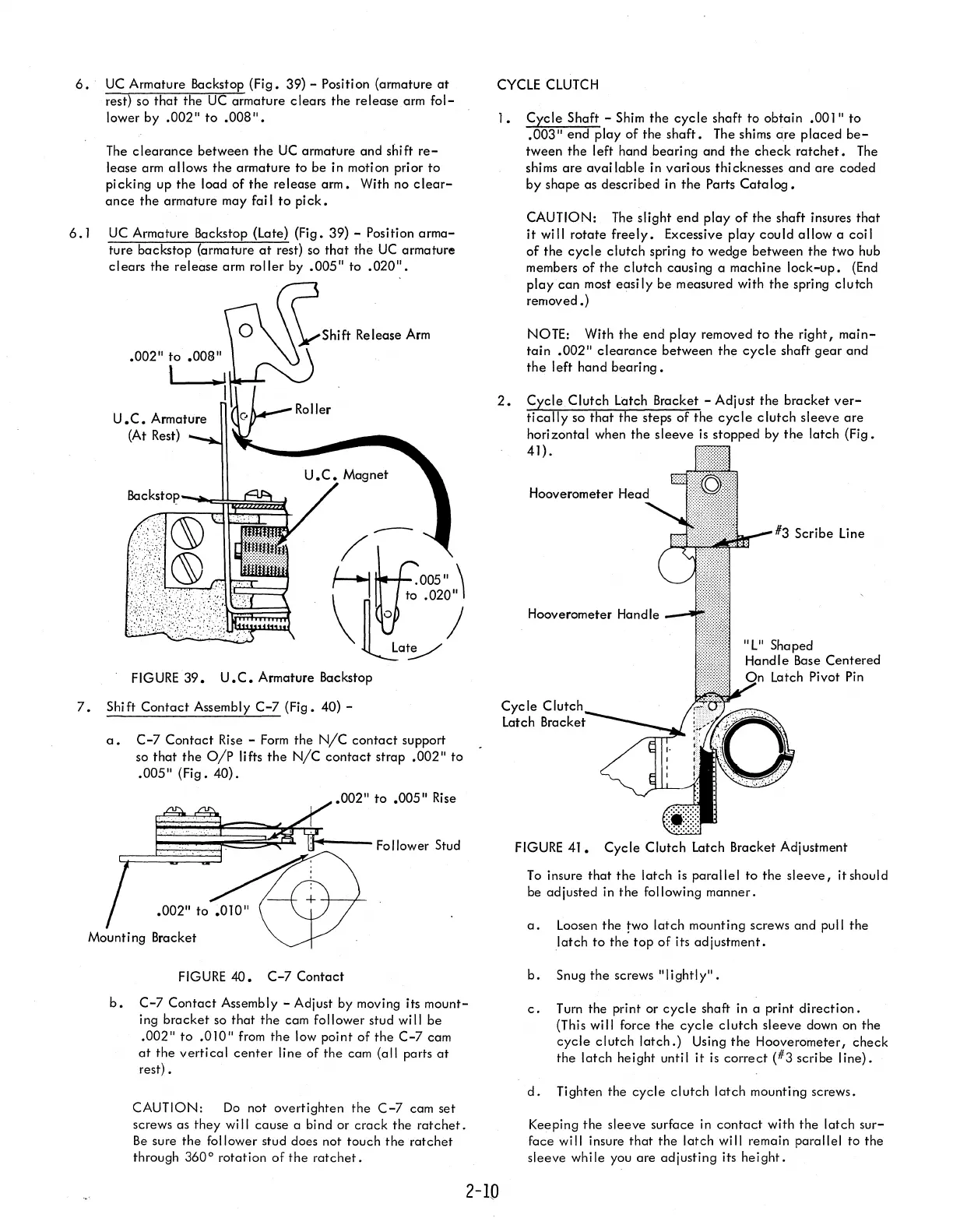

6.·

UC

Armature Backstop

(Fig.

39) - Positi

on

(armature

at

rest) so

that

the

UC

armature clears

the

release arm

fol-

lower by

.002"

to

.008".

The

clearance

between

the

UC

armature and shift

re-

lease arm allows

the

armature to

be

in motion prior

to

pi

cking up

the

load

of

the

release

arm.

With no

clear-

ance

the

armature may fai I

to

pick.

6.

I

UC

Armature Backstop (Late) (Fig. 39) - Position

arma-

ture backstop {armature

at

rest} so

that

the

UC

armature

clears

the release arm

roller

by

.005"

to

.020".

FIGURE

39.

U.C.

Armature Backstop

7.

Shift

Contact

Assembly

C-7

(Fig. 40) -

--

Lay

a.

C-7

Contact

Rise

-

Form

the

N/C

contact

support

so

that

the

alp lifts

the

NIC

contact

strap

.002"

to

.005"

(Fig.

40).

.002"

to

.005"

Rise

"'=!~~~~~~~~!~---

Follower Stud

Mounting Bracket

FIGURE

40.

C-7

Contact

b.

C-7

Contact

Assembly - Adjust by moving its mount-

ing

bracket

so

that

the

cam follower stud will

be

.002"

to

.010"

from

the

low point

of

the

C-7

cam

at

the

vertical

center

line of

the

cam (all parts

at

rest) •

CAUTION:

Do

not overtighten the

C-7

cam set

screws as they

wi

II

cause a bind or

crack

the

ratchet.

Be

sure the follower stud does not touch

the

ratchet

through 360

0

rotation

of

the

ratchet.

CYCLE

CLUTCH

I.

Cycle

Shaft -

Shim

the

cycle

shaft to obtain

.001"

to

.003"

end play

of

the

shaft.

The shims

are

placed

be-

tween

the

left hand

bearing

and

the

check

ratchet.

The

shims

are

available

in various thicknesses

and

are

coded

by

shape as described in

the

Parts

Catalog.

CAUTION:

The

slight

end

play

of

the

shaft insures

that

it

will

rotate

freely.

Excessive

play

could

allow

a coil

of

the

cycle

clutch

spring to wedge between

the

two hub

members

of

the

clutch

causing a machine

lock-up.

(End

play

can

most

easily

be measured with

the

spring clutch

removed.)

NOTE: With

the

end

play

removed

to

the

right I

main-

tain

.002"

clearance

between

the

cycle

shaft

gear

and

the

left hand

bearing.

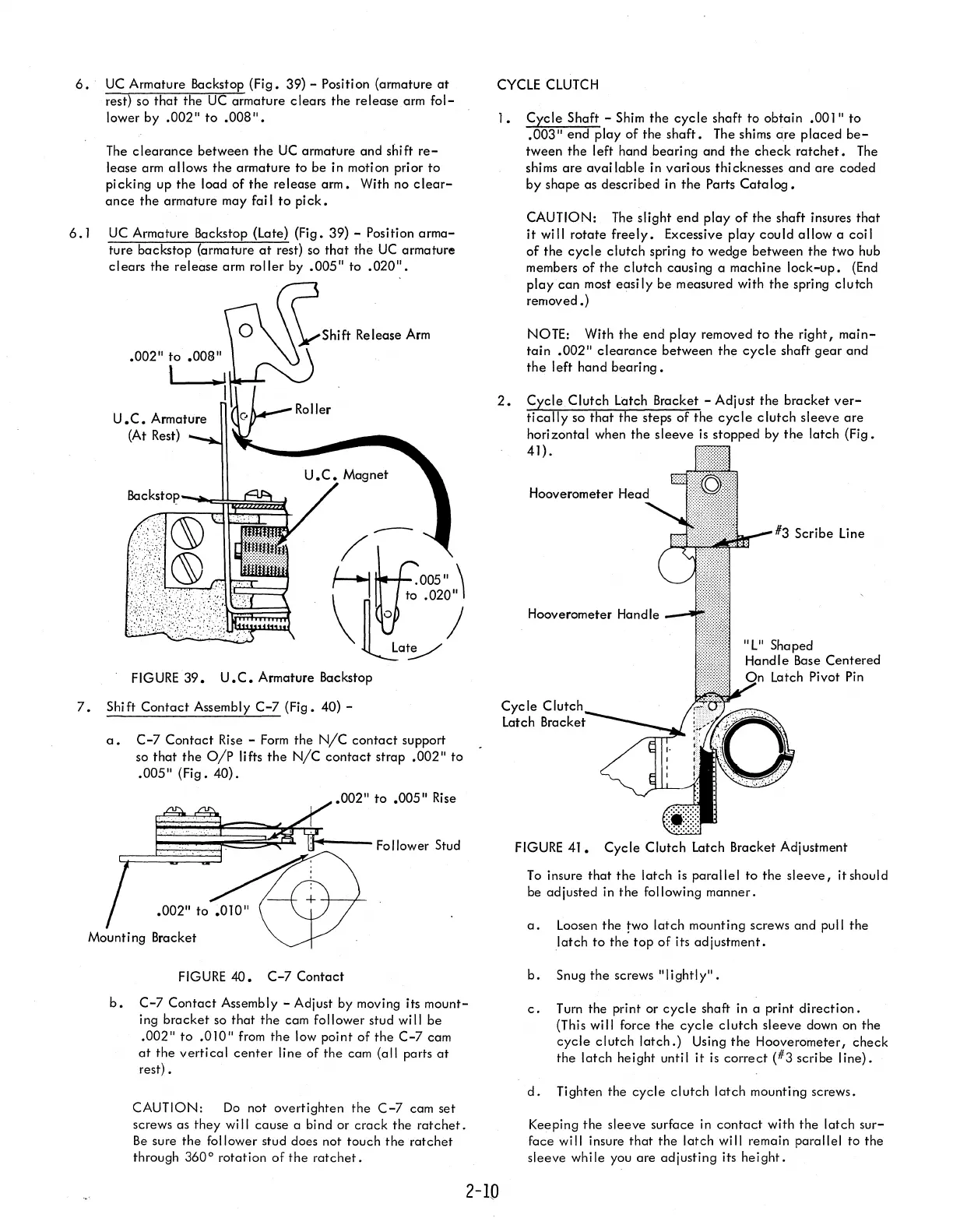

2.

Cycle

Clutch Latch Bracket - Adjust the

bracket

ver-

tically

so

that

the

steps

of

the

cycle

clutch

sleeve

are

horizontal when

the

sleeve

is

stopped by

the

latch

(Fig.

41).

Hooverometer Handle

Cycle

C

Latch Bracket

"L" Shaped

Handle

Base

Centered

Latch Pivot

Pin

FIGURE

41.

Cycle

Clutch Latch Bracket Adjustment

To

insure

that

the

latch is parallel to

the

sleeve,

itshould

be adjusted in

the

following manner.

a.

Loosen

the

two

latch

mounting screws and pull the

.Iatch

to

the

top

of

its ad justment.

b.

Snug

the

screws

"lightly".

c.

Turn the print or

cycle

shaft in a print

direction.

(This will force the

cycle

clutch

sleeve down on

the

cycle

clutch

latch.)

Using

the

Hooverometer I

check

the

latch

height until

it

is

correct

{#3 scribe line}.

d.

Tighten the

cycle

clutch

latch

mounting screws.

Keeping

the

sleeve surface in

contact

with the

latch

sur-

face will insure

that

the

latch

will remain parallel to the

sleeve while you

are

adjusting its

height.

2-10

Loading...

Loading...