will

slightly

affect

the

adjustment

at

the

other

end.

Be

sure

to

recheck

each

adjustment.

Anvil

Frame

Power

______________

~*

Frame

Buffer

Anvil

Locking

Screws

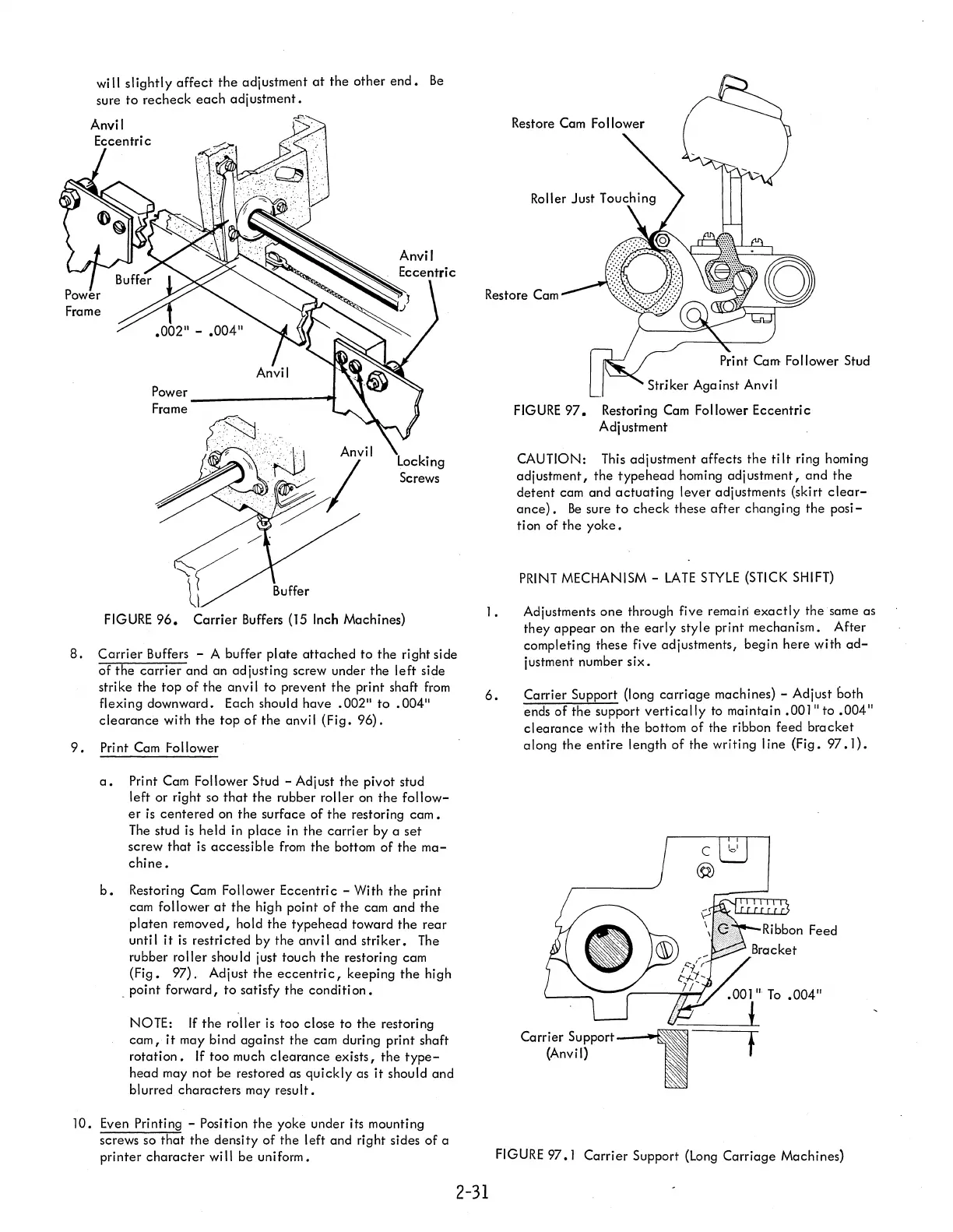

FIGURE

96.

Carrier

Buffers

(15

Inch Machines)

8.

Carrier

Buffers - A buffer

plate

attached

to

the right side

of

the

carrier

and an adjusting screw under

the

left

side

strike

the

top

of

the

anvil to prevent

the

print shaft

from

flexing downward. Each should

have

.002"

to

.004"

clearance

with

the

top

of

the

anvil

(Fig.

96).

9.

Print Cam Follower

a.

Print Cam Follower Stud - Adjust

the

pivot stud

left or right so

that

the

rubber roller on

the

follow-

er

is

centered

on

the

surface

of

the

restoring

cam.

The stud

is

held

in

place

in

the

carrier

by a

set

screw

that

is

accessible

from

the

bottom

of

the

ma-

chine.

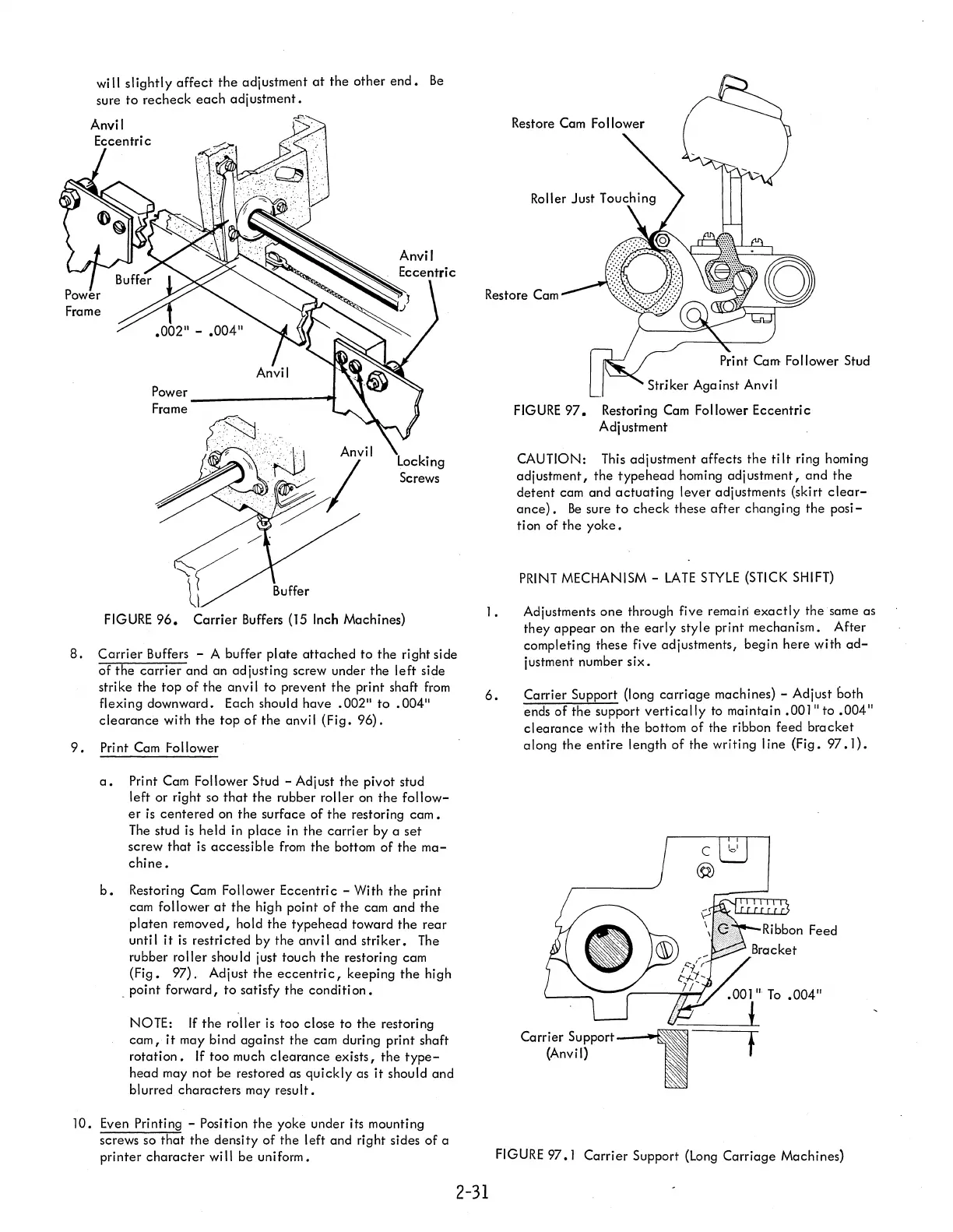

b.

Restori

ng

Cam

Fo

II

ower Eccentri c -

Wi

th

the

pri nt

cam follower

at

the

high point

of

the

cam

and

the

platen

removed, hold

the

typehead

toward

the

rear

until

it

is

restri

cted

by the anvi I and

striker.

The

rubber roller should just touch

the

restoring cam

(Fig.

97). Adjust

the

eccentric,

keeping

the

high

_ point forward,

to

satisfy the

condition.

NOTE:

If

the

roller

is

too

close to

the

restoring

cam,

it

may bind

against

the cam during print shaft

rotation.

If too much

clearance

exists,

the

type-

head

may not be restored as

quickly

as

it

should and

blurred

characters

may

result.

10.

Even Printing - Position

the

yoke under its mounting

screws so

that

the

density

of

the

left and right sides

of

a

printer

character

wi

II

be uniform.

Restore

Cam

1.

6.

Striker Aga inst Anvi I

FIGURE

97.

Restoring Cam Follower Eccentric

Adjustment

CAUTION: This adjustment affects

the

ti It ring homing

adjustment,

the

typehead

homing

adjustment,

and

the

detent

cam and

actuating

lever

adjustments (skirt

clear-

ance).

Be

sure

to

check

these

after

changing

the

posi-

ti

on

of

the

yoke.

PRINT

MECHANISM -

LATE

STYLE

(STICK SHIFT)

Adjustments

one

through five remain

exactly

the same as

they

appear

on

the

early

style print mechanism.

After

completing

these

five adjustments, begin

here

with

ad-

justment number

six.

Carrier Support (long

carriage

machines) - Adjust both

ends

of

the

support

vertically

to maintain

.001"

to

.004"

clearance

with the bottom

of

the ribbon feed

bracket

along

the

entire

length

of

the writing

line

(Fig.

97.1).

.001"

To

.004"

!

t

FIGURE

97.

I

Carrier

Support (Long

Carriage

Machines)

2-31

Loading...

Loading...