Excessive

Band

Wi

dth Between

o (zero) and -1

-3

and

+5

-3,

+5

and

0 (zero)

-5

and

-3

Cause

Incorrect

balance

Incorrect

rotate

arm motion

Incorrect

latch

clearances

Incorrect paddle adjustment

Unwanted compensator roller droppage may result from

one

or more

of

the

following.

a.

Improper

detent

timing

b.

Malselection

(popping latches)

c.

Incorrect

rotate

spring tension

or

damper spring

ten-

sion.

d.

Binds in

the

typehead,

upper ball

socket,

rotate

shaft,

rotate

pulley,

or

rotate

spring.

e.

Binds in

the

compensator

or

lever

system.

f. Loose

differential

mounting

bracket.

g.

Excessive band width or

head

play.

If

the

band width appears

to

be

all

right but

the

align-

ment

is

not

satisfactory,

check

the

following items:

a.'

Detent timing

b.

Play or binds in

the

tilt

or

rotate

detents.

Side

play

in

the

rotate

detent

can

be

checked

by

repeating

any

full

size

character

such as

the

letter"

N"

so

that

it

repeats

for a full

line.

Move

the

carrier

backman-

ually

and

repeat

the

operation

without

indexing.

The

second line should

cover

the

first line

exactly.

If

any

of

the

characters

are

shadowed, side

play

in

the

rotate

detent

could

be the

cause.

c.

Loose fitting upper

ball

socket

Copy Control Lever

Copy Control

Ecc.

d.

Excessive

play

in

the

carrier

or rocker

e.

Binds

in the rocker parts

f.

If

the

-5

characters

vary

horizontally,

improper

damper spring tension cou

Id

be

the

cause.

g.

Improper ti

It

adjustments

can

cause

poor

horizontal

alignment by

delaying

the

detent,

seating.

NOTE: After

the

machine

has been in use for some time

wear in

the

tape

system will

allow

the

typehead

to

drift

in

the

negative

di recti

on.

It

is

not necessary

to

slip

the

rotate

shaft within

the

rotate

pulley

to

REFINE

the

type-

head

position.

The proper position may be

gained

by

re-

fining the

eccentric

stud

adjustment.

Be

sure

to

RESEAT

the

compensator

roller

after

changing

the

eccentri

c stud

adjustment.

(Maintain

the

roller

position

1/16"

from

the

top of the

slot

by adjustment

of

the

rotate

link.)

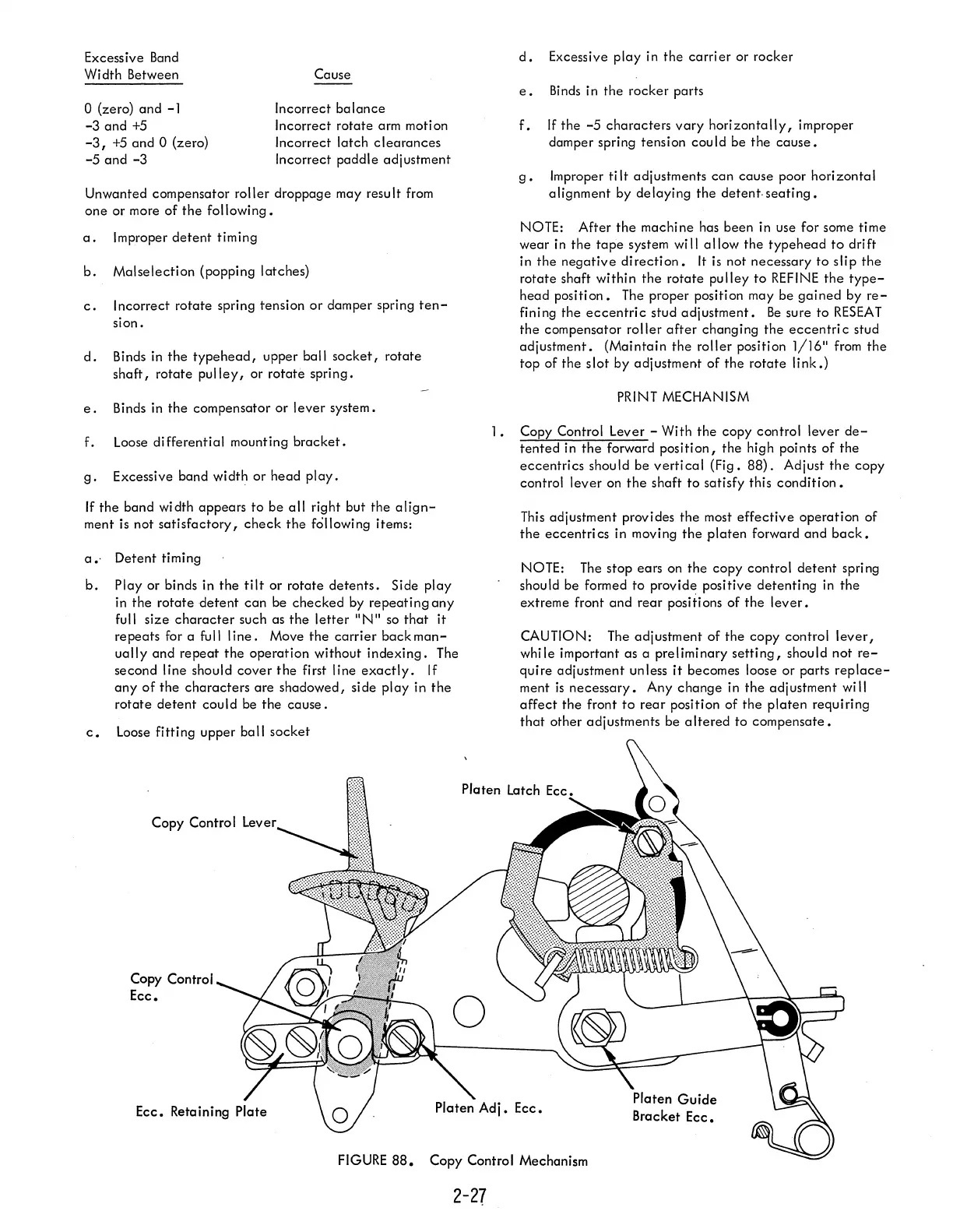

PRINT MECHANISM

1.

Copy Control Lever - With

the

copy control

lever

de-

tented

in

the

forward

position,

the

high points

of

the

eccentrics

should be

vertical

(Fig.

88).

Adjust

the

copy

control

lever

on

the

shaft

to

satisfy this

condition.

This

adjustment provi des

the

most

effective

operation

of

the

eccentri

cs

in moving

the

platen

forward

and

back.

NOTE: The stop ears on

the

copy control

detent

spri

ng

should be formed

to

provide positive

detenting

in

the

extreme front

and

rear

positions

of

the

lever.

CAUTION: The adjustment

of

the

copy control

lever,

while important as a preliminary

setting,

should not

re-

quire

adjustment unless

it

becomes loose or parts

replace-

ment

is

necessary.

Any

change

in

the

adjustment will

affect

the front

to

rear

position of

the

platen

requiring

that

other adjustments be

altered

to

compensate.

FIGURE

88.

Copy Control Mechanism

2-27

Loading...

Loading...