not occurring

at

the

negative

four position, thus

the

arm

assembly

is

operating as one soli d arm

at

this position.

In

Figure 85C

the

correct amount

of

rati 0

change

is in

the

system. All positions

from

the

-3

to

the

+5

detent

the

same as

the

-5.

Note

that

when

the

-3

detents

the

same as

the

-5,

the detenting

of

the

-4

is

slightly

dif-

ferent.

This

is

caused by the ratio

change.

No

attempt

should be made to control

the

detenting

of

the

-4

posi-

tion because its position may vary

on

each

machine

de-

pending

on

the

amount of ratio change required (of

each

machine)

to

make

the

-3

detent

the same as

the

-5.

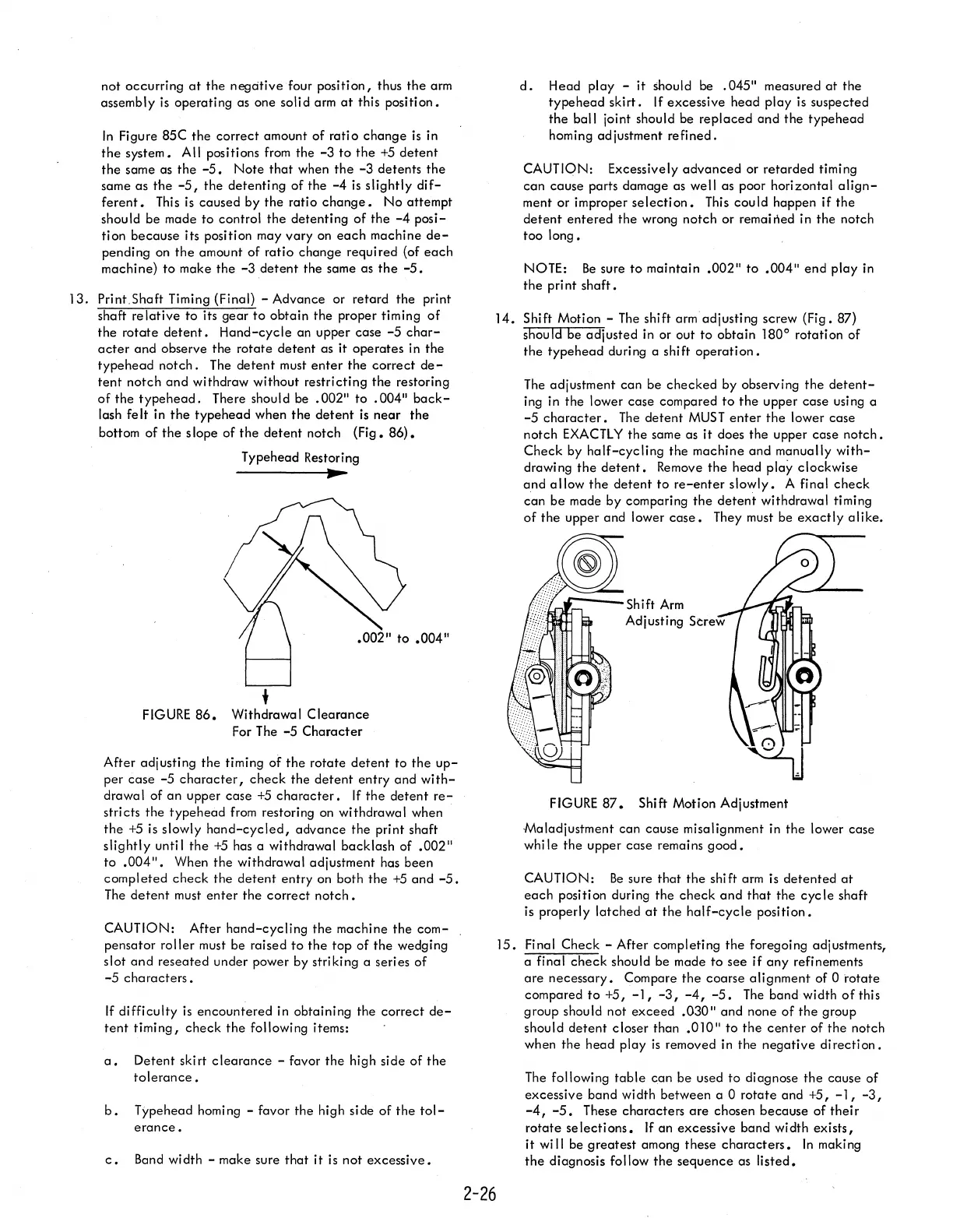

13.

Print.Shaft Timing (Final) - Advance or retard the print

shaft

relative

to

its gear

to

obtain the proper timing

of

the

rotate

detent.

Hand-cycle

an upper case

-5

char-

acter

and observe the rotate

detent

as it operates in the

typehead

notch.

The

detent

must

enter

the

correct

de-

tent

notch

and

withdraw without restricting

the

restoring

of

the

typehead.

There should be

.002"

to

.004"

back-

lash

felt

in

the

type head when the

detent

is

near

the

bottom

of

the

s lope of

the

detent

notch

(Fig.

86).

Typehead Restoring

~

t

FIGURE

86.

Withdrawal

Clearance

For The

-5

Character

After adjusting

the

timing

of

the

rotate

detent

to

the

up-

per case

-5

character,

check

the

detent

entry

and

with-

drawa I of

an

upper case

+5

character.

If

the

detent

re-

stricts

the

typehead

from

restoring

on

withdrawal when

the

+5

is slowly

hand-cycled,

advance

the

print shaft

slightly

until

the

+5

has a withdrawal backlash of

.002"

to

.004".

When

the

withdrawal adjustment has been

completed check the

detent

entry on both

the

+5

and

-5.

The

detent

must

enter

the correct

notch.

CAUTION: After

hand-cycling

the

machine

the

com-

pensator roller must be raised

to

the

top

of

the

wedging

slot

and

reseated under power by striking a series

of

-5

cha

racters.

If

difficulty

is

encountered in obtaining the correct

de-

tent

timing,

check

the

following items:

a.

Detent ski

rt

clearance

- favor

the

high side

of

the

tolerance.

b.

Typehead homing - favor

the

high side

of

the

tol-

erance.

c.

Band width - make sure

that

it

is

not

excessive.

2-26

d.

Head play -

it

should be

.045"

measured

at

the

type head

skirt.

If excessive head play is suspected

the

ball joint should be

replaced

and

the

typehead

homing adjustment

refined.

CAUTION: Excessively

advanced

or retarded timing

can

cause parts damage as well as poor horizontal

align-

ment

or

improper

selection.

This

could happen

if

the

detent

entered

the

wrong notch or remai ned in

the

notch

too long.

NOTE:

Be

sure

to

maintain

.002"

to

.004"

end

play in

the

pri nt

shaft.

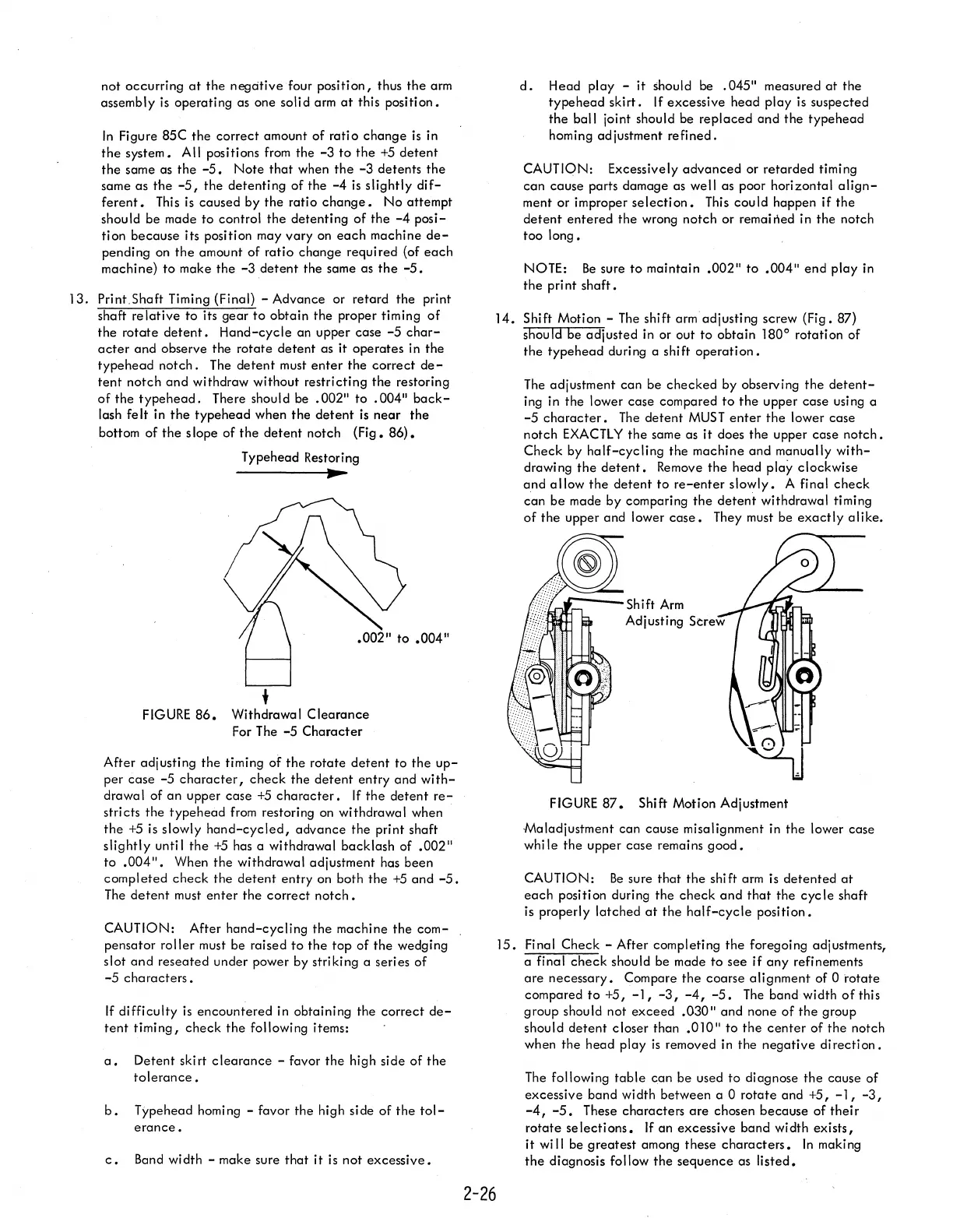

14.

Shift Motion -

The

shift arm adjusting screw (Fig. 87)

should be adjusted in or out to obtain

180

0

rotation

of

the

typehead

during a shift

operation.

The

adjustment can be

checked

by observing

the

detent-

ing in

the

lower case compared

to

the

upper case using a

-5

character.

The

detent

MUST

enter

the

lower case

notch

EXACTLY

the

same as

it

does the upper case

notch.

Check by

half-cycling

the machine

and

manually

with-

drawing

the

detent.

Remove

the

head play clockwise

and

allow

the

detent

to

re-enter

slowly.

A final

check

~an

be made by comparing

the

detent

withdrawal timing

of

the

upper and lower

case.

They must be

exactly

alike

•

.1:"'--_

Sh

i ft

Arm

Adjusting Screw

...

~

FIGURE

87.

Shift Motion Adjustment

Maladjustment can cause misalignment in

the

lower case

while the upper case remains

good.

CAUTION:

Be

sure

that

the shift arm is detented

at

each

position during the

check

and

that

the

cycle

shaft

is properly latched

at

the

half-cycle

position.

15.

Final Check - After completing

the

foregoing adjustments,

a final

check

should be made

to

see

if

any

refinements

are

necessary. Compare

the

coarse alignment of 0

rotate

compared

to

+5,

-1, -3,

-4, -5.

The

band width

of

this

group should not

exceed

.030"

and none

of

the

group

should

detent

closer than

.010"

to

the

center

of

the

notch

when the head play

is

removed in the

negative

direction.

The

following

table

can be used

to

diagnose

the

cause

of

excessive band

wi

dth between a 0 rotate and

+5,

-1,

-3,

-4, -5.

These characters

are

chosen because

of

thei r

rotate

se lecti ons. If an excessive band

wi

dth exists,

it

wi

II

be

greatest

among these

characters.

In

making

the

diagnosis follow

the

sequence as

listed.

Loading...

Loading...