Position

to

Governor

Pinion For

.00211

to

.004

11

Backlash

Operational

Shaft

Tab Pinion

Gear

CollarR

Tab Governor Spring

Tab Governor Arbor

FIGURE

109.

Tab Governor Pinion

3.

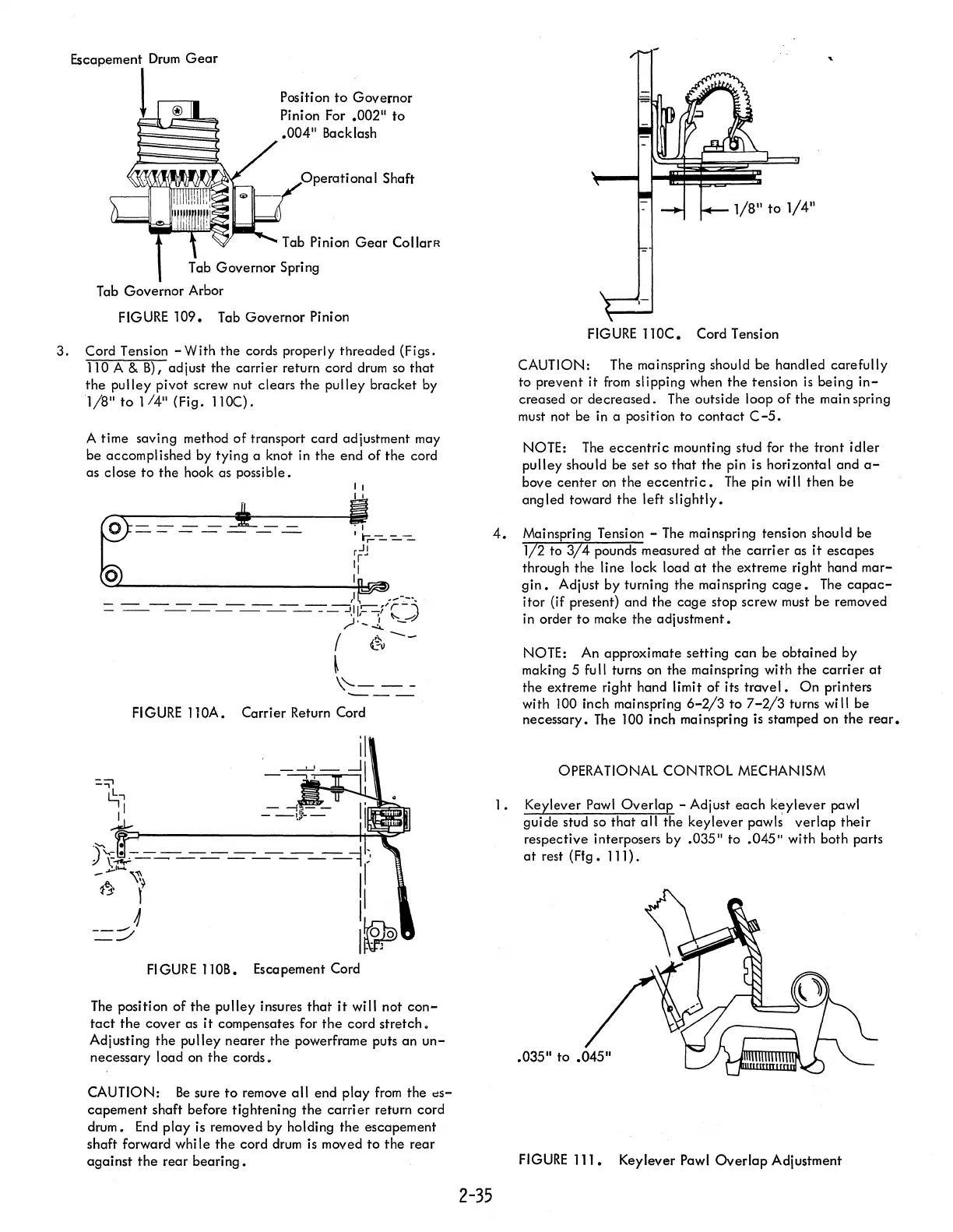

Cord Tension - With

the

cords properly threaded (Figs.

110 A &

B)

I adjust the

carrier

return cord drum

so

that

the

pulley

pivot screw nut clears the

pulley

bracket by

1/8"

to

1/4"

(Fig. I1OC).

A time saving method

of

transport card adjustment may

be accomplished by tying a knot in the end of the cord

as close

to

the hook as possible.

II

I

,I

.~-._'.

- -

--

-

--

---.-

'r-)

-

--

-----

___

--

JII--f

,I

,

,,~

,)'-~

-

(

L~--

~

\'--

--

---

FIGURE

1 lOA. Carrier Return Cord

il

,

_...J..J_

..JI

-

---,.

Ii

)

''''''

=l

\,-

------

--

- .

.

\~---------:

~~

I

-

e..

\~~

I

b \ I

4 I

=::/

I~

FIGURE

110B. Escapement Cord

The

position of

the

pulley

insures

that

it

wi

II

not

con-

tact

the

cover

as

it

compensates for

the

cord

stretch.

Adjusting

the

pulley

nearer the powerframe puts an

un-

necessary load on

the

cords.

CAUTION:

Be

sure

to

remove

all

end play

from

the

dS-

capement shaft before tighteni

ng

the

carri

er

return cord

drum.

End

play is removed by holding

the

escapement

shaft forward while

the

cord

drum

is moved

to

the

rear

against

the

rear

bearing.

2-35

"

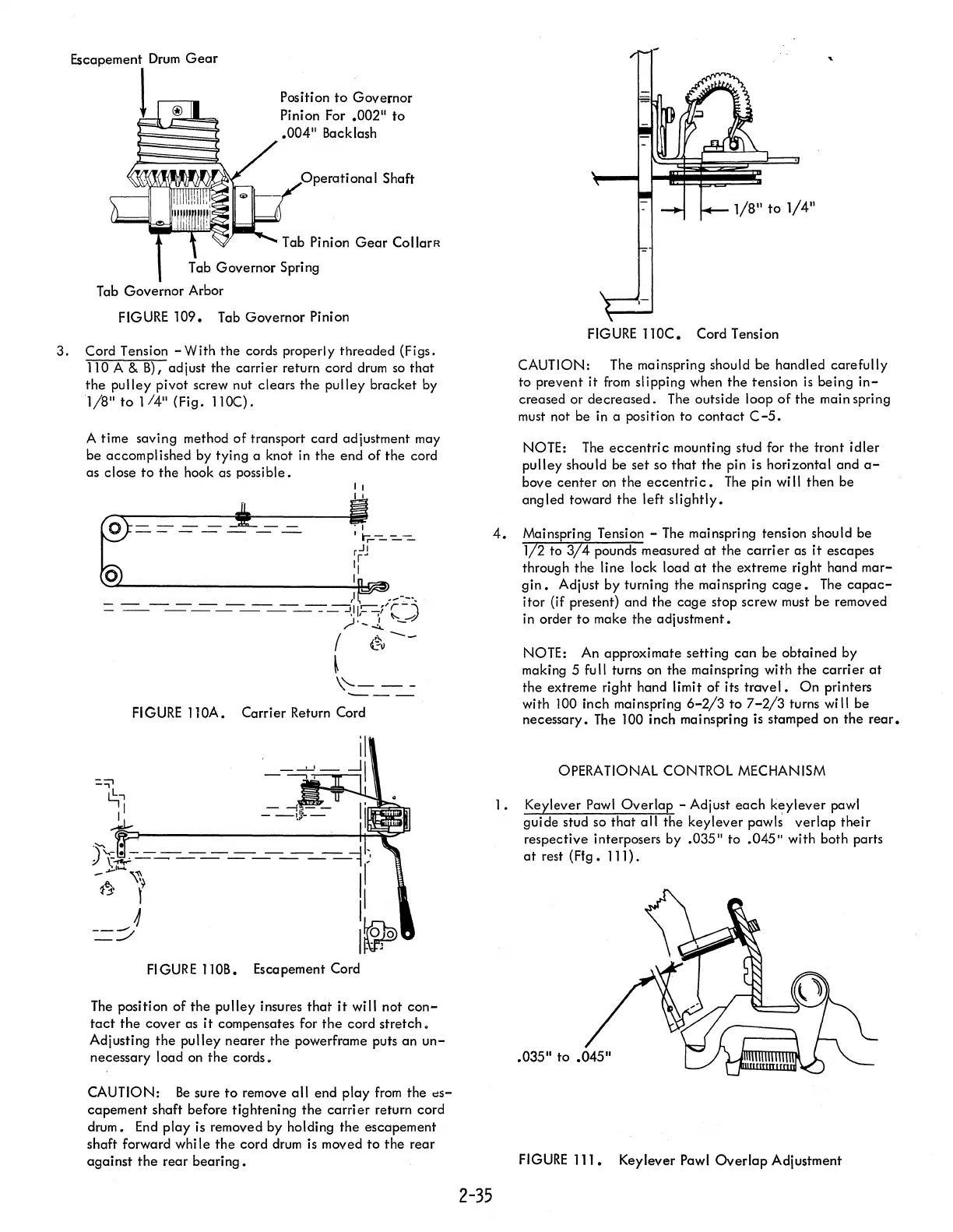

FIGURE

110C.

Cord Tension

CAUTION: The mainspring should be handled carefully

to prevent

it

from

sl

ipping when

the

tension

is

being

in-

creased or

decreased.

The outside loop

of

the main spring

must

not be in a position to

contact

C-5.

NOTE:

The

eccentric

mounting stud for

the

trontidler

pulley should be

set

so

that

the

pin is horizontal and

a-

bove

center

on

the

eccentri

c.

The

pin will then be

ang led toward the left

slightly.

4.

Mainspring Tension -

The

mainspring tension should be

1/2

to

3/4

pounds measured

at

the

carrier

as

it

escapes

through

the

line lock load

at

the

extreme right hand

mar-

gin.

Adjust by turning the mainspring

cage.

The

capac-

itor (if present) and the

cage

stop screw must

be

removed

in order

to

make

the

adjustment.

NOTE: An approximate setting

can

be obtained by

making 5 full turns on the mainspring with the

carrier

at

the extreme right hand limit of its

travel.

On

printers

with 100 inch mainspring

6-2/3

to

7-2/3

turns will be

necessary.

The

100 inch mainspring is stamped on the

rear.

OPERATIONAL CONTROL MECHANISM

1 • Keylever Pawl

Overlap

- Adjust

each

keylever

pawl

guide stud so

that

all

the keylever pawls

verlap

their

respective interposers by

.035"

to

.045"

with both parts

at

rest

(Fig.

111) .

FIGURE

111.

Keylever Pawl

Overlap

Adjustment

Loading...

Loading...